Carbonized biopolymers

A biopolymer and carbonized seaweed technology, which is applied in the preparation/purification of carbon, hybrid capacitors, hybrid capacitor electrodes, etc., can solve the problems of unstable surface modification and achieve low pore volume, high density, and high volume specific capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] precursor biopolymer

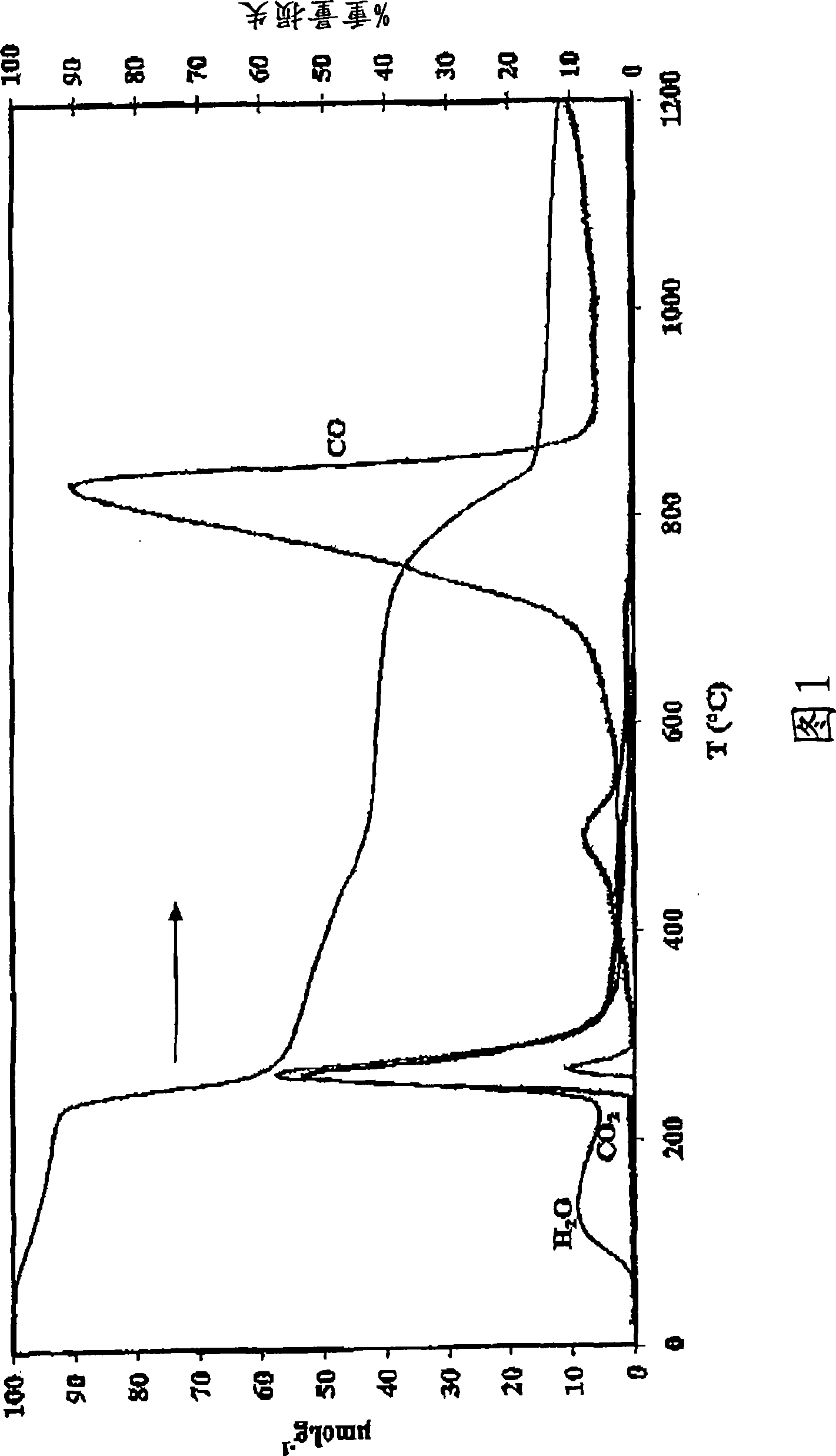

[0038] Carbonization was performed on several commercially available oxygen-rich biopolymers (alginate and carrageenan, see Table 1 ) extracted from seaweeds. Alginate is produced from brown seaweed. Carrageenan is a generic term for polysaccharides prepared by alkaline extraction (and modification) from red seaweed.

[0039] In addition, several species of seagrass that contain large amounts of these biopolymers were directly carbonized. Lessonia Nigrescens is an alginate-rich seaweed, while Hypnea Musciforme and Meristotheca Senegalensis contain high amounts of carrageenan.

[0040] Another promising precursor biopolymer is chitin. Chitin is an unbranched polymer of N-acetyl-D-glucosamine. Chitin is found in fungi and seaweeds, and is a major component of the exoskeletons of arthropods and lower animals, such as the shells of insects, crabs, and shrimp. It can be considered a derivative of cellulose in which the hydroxyl group of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com