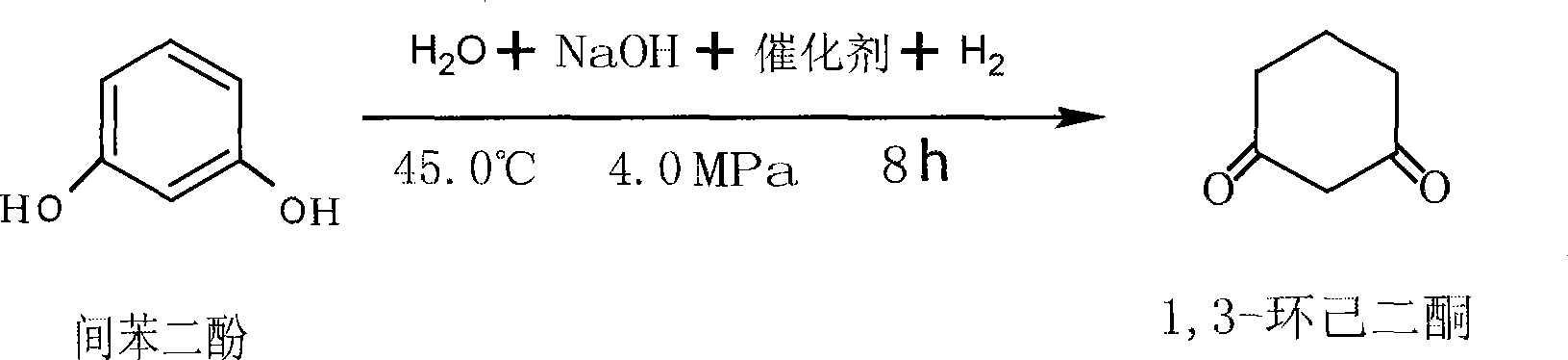

Industrial production method of 1,3-cyclohexanedione

A technology of cyclohexanedione and a production method, which is applied in 1 field, can solve the problems of inability to apply downstream products, increase in waste water treatment costs, influence post-treatment acidification, etc., so as to reduce the amount of hydrochloric acid added, the production of by-products, and the raw materials. Improved conversion rate and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 3000L stainless steel sealed feeding box, drop 800kg liquid caustic soda, 1300kg water, and drop 600kg resorcinol under stirring conditions. When the material is fully dissolved and the temperature is stable at 40-45°C, it is introduced into a 3000L stainless steel high-pressure reactor. Then add 20kg of modified skeleton nickel catalyst from the catalyst special port, close the high pressure valve after fully washing with water. Turn on the vacuum pump, close the vacuum valve after reaching the ultimate vacuum in the kettle, slowly introduce industrial hydrogen to 4MPa, and replenish hydrogen at any time to maintain the pressure. The observation temperature should be between 45 and 50°C. After maintaining the pressure and temperature for 8 hours, open the discharge valve, discharge the material into the sedimentation storage tank, and discharge the remaining gas through the safety emptying pipe, and the pressure is released to zero, ready for the next batch of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com