Preparation of germanium quantum point

The technology of quantum dots and cleaning solution is applied in the field of preparing germanium quantum dots, which can solve the problems of complex manufacturing process, high cost, small size and the like, and achieve the effects of simple manufacturing process, convenient growth and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

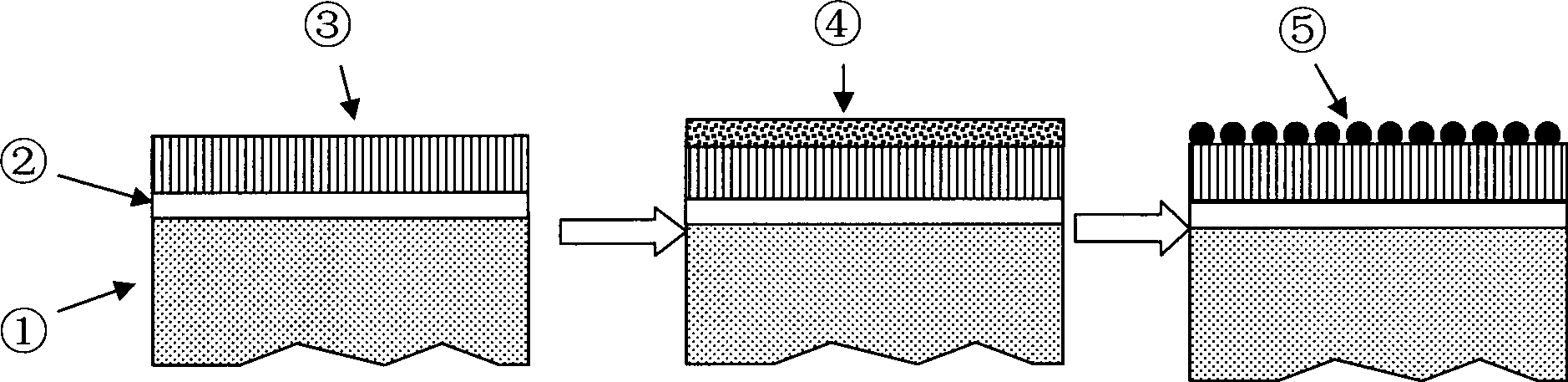

[0021] figure 1 A schematic flow chart of the preparation of Ge quantum dots by the method of high-temperature deoxidation in a vacuum chamber is given in the present invention. exist figure 1 The labels in ① are silicon substrate; ② silicon buffer layer; ③ SiGe alloy layer, the Ge composition is greater than 0 and less than or equal to 0.5; ④ the oxide coating layer formed after standard cleaning, its thickness is about 3nm; Ge quantum dots formed on the surface of SiGe film.

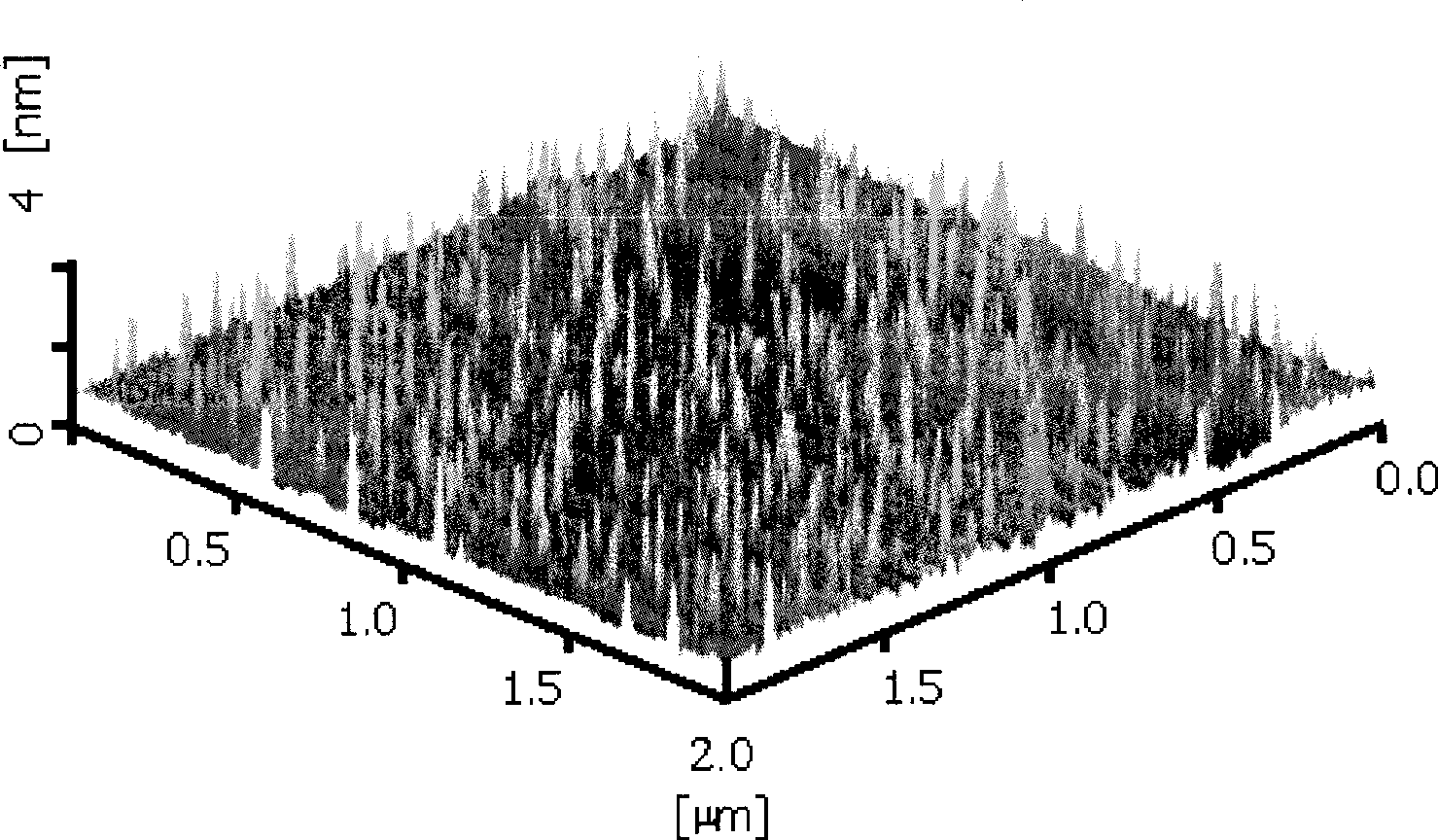

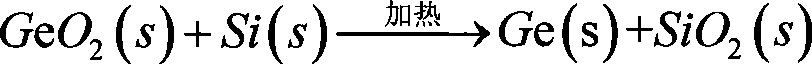

[0022] A 100nm Si buffer layer and a 200nm Si buffer layer were epitaxially grown sequentially on the Si substrate 0.94 Ge 0.06 Alloy layer; followed by cleaning solution No. III (according to the volume ratio, H 2 SO 4 :H 2 o 2 =4:1) and No. II cleaning solution (according to volume ratio, HCl:H 2 o 2 :H 2 (0=1:1:4) after cleaning, an oxide layer with a thickness of about 3nm is formed on the surface of the SiGe alloy layer; after drying with nitrogen, put it into the vacuum chamber immediat...

Embodiment 2

[0024] Similar to embodiment 1, its difference is that the cleaning method to SiGe alloy only adopts No. I cleaning solution (NH 4 OH:H 2 o 2 :H 2 O=1:1:4) for cleaning.

Embodiment 3

[0026] Similar to embodiment 1, its difference is that the cleaning method to SiGe alloy only adopts No. II cleaning solution (HCl: H 2 o 2 :H 2 O=1:1:4) for cleaning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com