Feedstuff for increasing meat chicken production performance and production method thereof

A technology of production performance and production method, which is applied in the field of feed for improving the production performance of broilers, can solve the problems of waste of amino acid, waste of crude protein, and unsatisfactory actual effect of amino acid, etc., and achieve improvement of breeding environment, reduction of pollution, and economical utilization of feed protein Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The feed for improving the production performance of broilers in this embodiment includes the following components in parts by weight: 510 parts of corn, 160 parts of secondary meal, 260 parts of base material, 35 parts of meat and bone meal, 12 parts of lard, and 3 parts of lysine hydrochloride , 1 part of DL-methionine, 1 part of threonine, 6 parts of calcium carbonate, 12 parts of 1% broiler premix.

[0017] Among them, the composition of the basic material is: 30 parts of soybean meal, 15 parts of cottonseed meal, 25 parts of rapeseed meal, 10 parts of corn gluten meal, 5 parts of distiller's grain protein feed DDGS, 4 parts of brewer's grains, 4 parts of fermented bean products, and 7 parts of blood meal share.

[0018] Its preparation method is as follows: first, the above-mentioned raw materials are pulverized with a micro-powder machine, and 85% of the pulverized particle size is passed through a 80-150 mesh sieve. 80-85°C, the pressure is 0.3-0.4 MPa.

Embodiment 2

[0020] The feed for improving the production performance of broilers in this embodiment includes the following components in parts by weight: 555 parts of corn, 145 parts of secondary meal, 245 parts of base material, 30 parts of meat and bone meal, 10 parts of lard, and 2 parts of lysine hydrochloride , 0.5 parts of DL-methionine, 0.5 parts of threonine, 4 parts of calcium carbonate, 8 parts of 1% broiler premix.

[0021] The base material consists of: 20 parts of soybean meal, 14 parts of cottonseed meal, 33 parts of rapeseed meal, 9 parts of corn gluten meal, 6 parts of DDGS, 4 parts of brewer's grains, 6 parts of bean fermented product and 8 parts of blood meal.

Embodiment 3

[0023] Each composition of present embodiment is made up as follows:

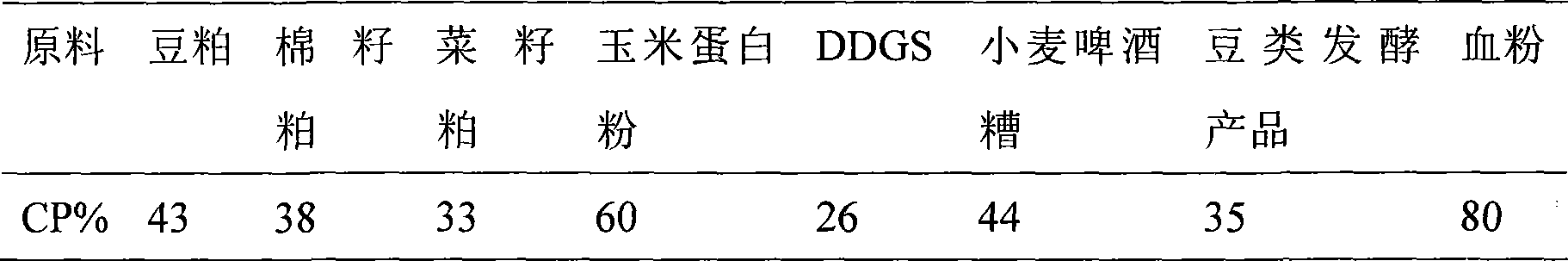

[0024] Table 1 Protein content of feed ingredients

[0025]

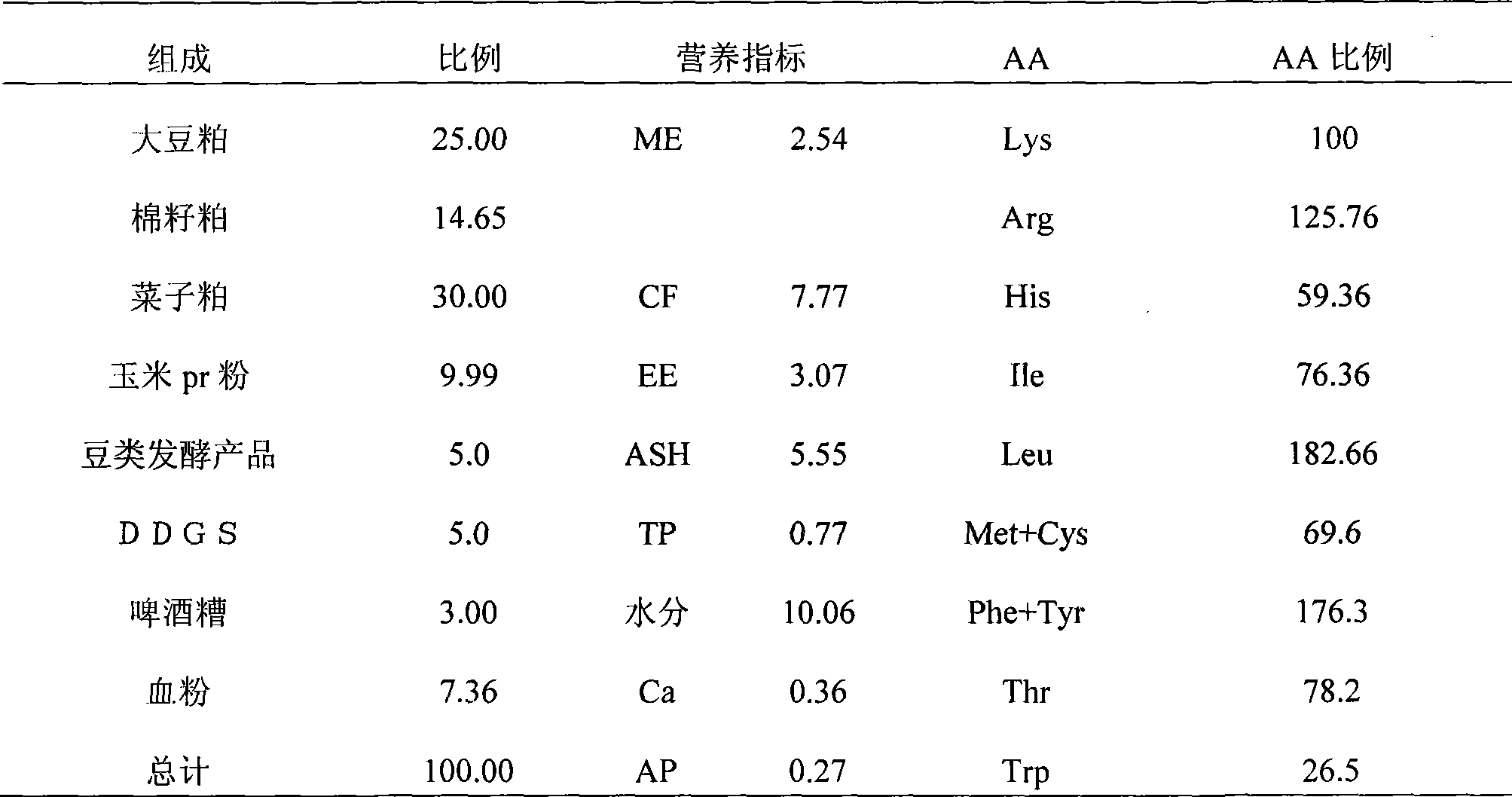

[0026] Table 2 Combination ratio mode of unconventional protein raw materials (%)

[0027]

[0028] Table 3 Composition and main nutritional indicators of complex proteins from unconventional protein sources (%)

[0029]

[0030]

[0031] Table 4 Diet Composition and Nutrients (%)

[0032]

[0033]The compound protein of 8 kinds of non-conventional protein sources with optimal nutritional combination balance was used to replace the total protein content provided by the protein raw materials in the commercial feed to formulate the diet, and its effect on the amino acid balance of the diet was studied. Using the computer, combined with the knowledge of animal nutrition and feed science, using the above model to optimize the dynamic combination of unconventional protein feed, 10 essen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com