Preparation method of ageing resistance compounding agent of wet flour

An anti-aging and compounding agent technology, applied in food science, food preservation, application, etc., can solve the problems of inconvenient anti-aging, easy oxidative rancidity of oil, and unbalanced oil ratio, so as to promote the formation of gluten network and low production cost , the effect of inhibiting recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the preparation method of anti-aging composite agent

[0037] The selected components are mixed in the following percentages by weight: fungal alpha-amylase 10.6%, gluten 58.2%, konjac gum 16.5%, sorbitan monostearate 14.7%, by 1:10 (W / W ) was dissolved in 0.01% (W / W) brine, then heated and stirred. The heating temperature is 45°C, and the product is obtained after emulsification and homogenization for 25 minutes.

Embodiment 2

[0038] Embodiment 2, the manufacturing process of wet face

[0039]Glucose amylase 0.0019kg (5.5%), carrageenan 0.006kg (17.3%), sorbitan monostearate 0.0058kg (16.7%), beta-cyclodextrin 0.021kg (60.5%), 0.01% (W / W) brine 0.33kg. Prepare the anti-aging compound agent according to the selected raw materials, then add this mixing liquid into the flour drop by drop, and mix the dough in a small dough mixer for 5 minutes to make the flour absorb water fully and evenly. Then mature in a constant temperature and humidity box at 25°C for 20 minutes. Press into sheets to form fine-textured, cohesive, uniform, flat and smooth noodle strips. Mature the noodle strips for 15 minutes, continue to press until the thickness is 2mm, cut into 2mm wide noodles, and then cook in boiling water for 8mim. Immediately wash with water for 1min. Then carry out pickling, the pickling solution is lactic acid-sodium lactate buffer solution with pH 2.7, soak for 2 minutes. Carry out vacuum packing aga...

Embodiment 3

[0040] Embodiment 3, the anti-aging composite agent of wet face is made up of the raw material of following weight percent:

[0041] Fungal Alpha-Amylase 11.0%

[0042] Gluten 55.7%

[0043] Guar Gum 16.7%

[0044] Glyceryl monostearate 16.6%

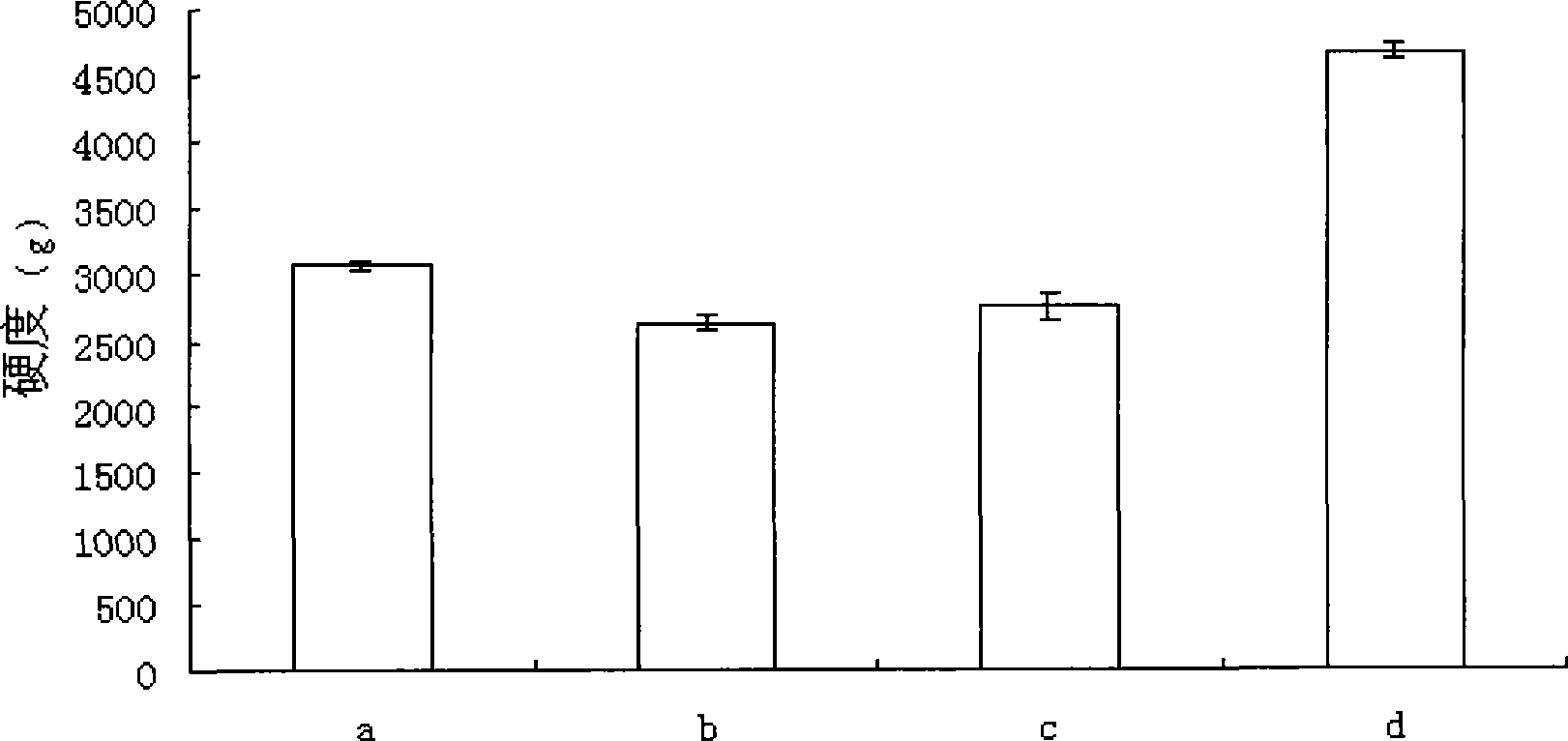

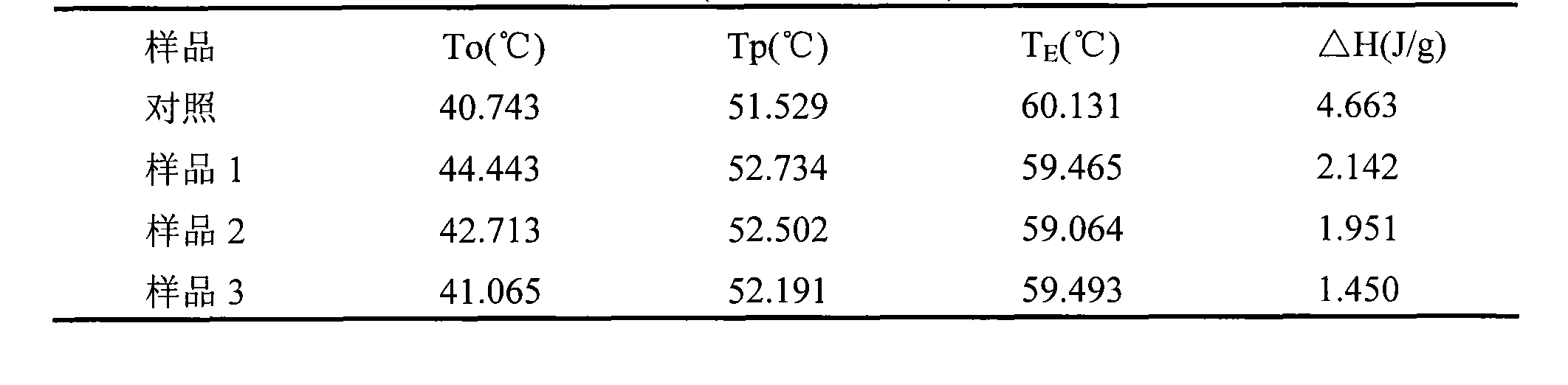

[0045] The wet noodle made of this formula with 0.01% (W / W) salt water and all-purpose flour at a ratio of 1:10:33 (W / W / W) is sample 1, and the DSC data (△H) after 30 days of storage See attached table, the improvement rate of recrystallization is 54.1%. The change in hardness of sample 1 (a represents sample 1) after storage for 30 days is shown in the attached figure, and the hardness improvement rate is 34.17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com