Small-sized coal gasification hydrogen making method

A small, coal gasification technology, applied in hydrogen separation, hydrogen production, chemical industry, etc., can solve the problems of high hydrogen cost, high natural gas price, difficult supply, etc., and achieve low hydrogen cost, low production energy consumption, and hydrogen cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed description will be given below in conjunction with the embodiments and accompanying drawings.

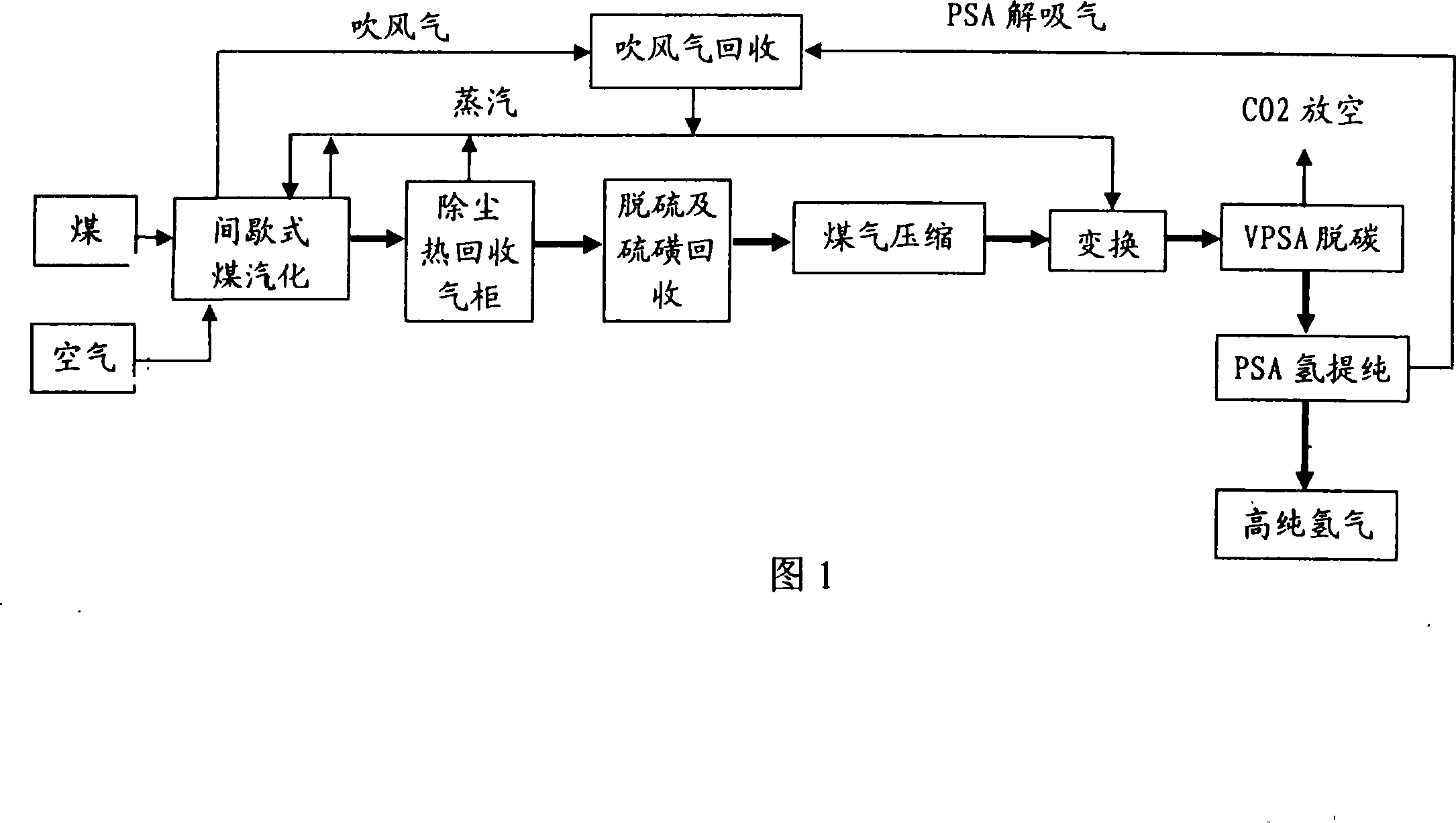

[0019] See figure 1 As shown, the present invention uses anthracite as a raw material to produce hydrogen, including interstitial coal gasification, blown gas recovery, water gas dust removal and heat recovery device, desulfurization and sulfur recovery, water gas compression and conversion, VPSA decarburization, PSA hydrogen purification and other parts of the process and corresponding equipment. The gist of the present invention is to combine the processes and equipment of each part into a complete process flow to achieve the purpose of using coal to produce hydrogen. As far as the local and single equipment is concerned, the principles and structures are well known.

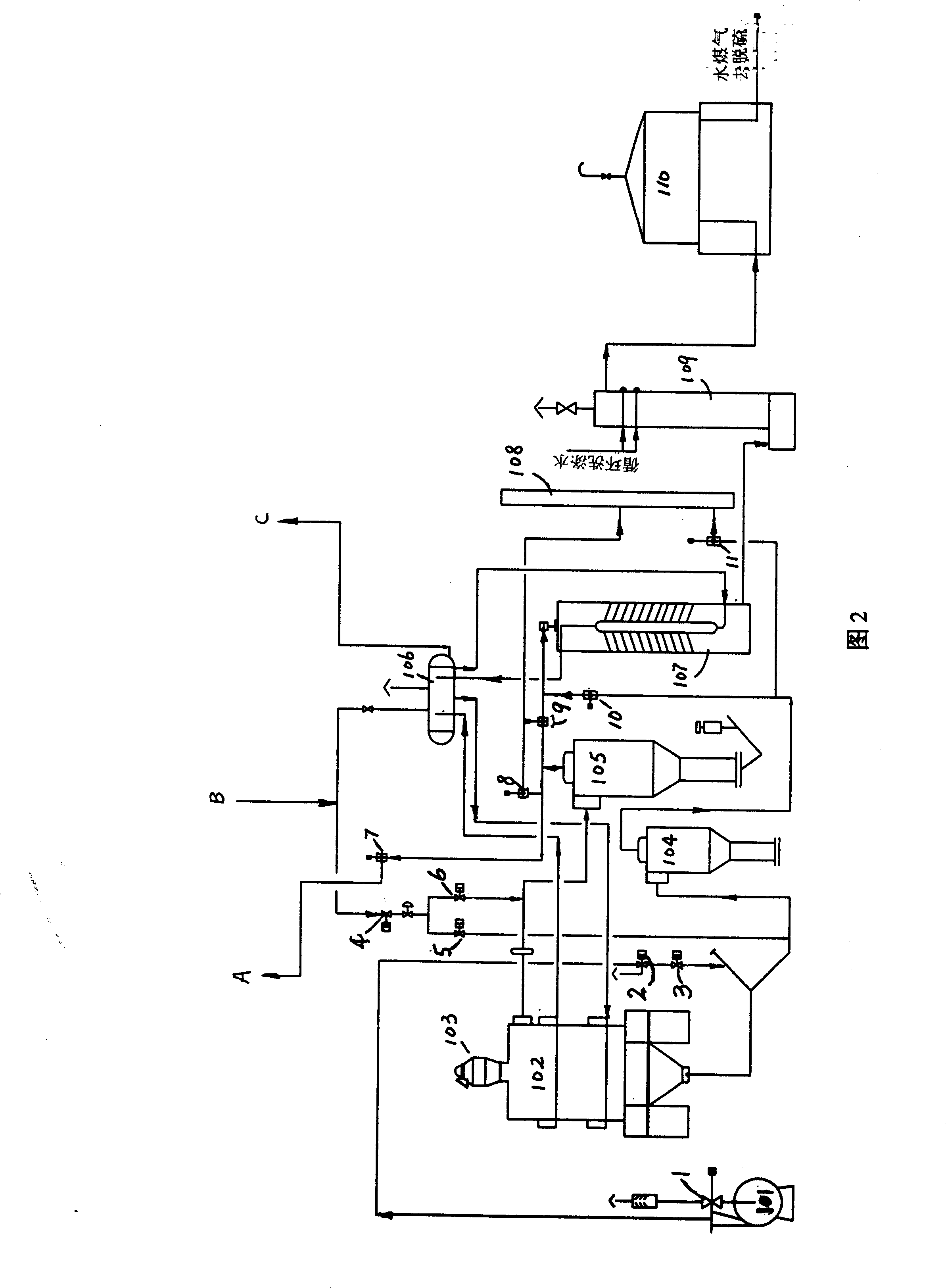

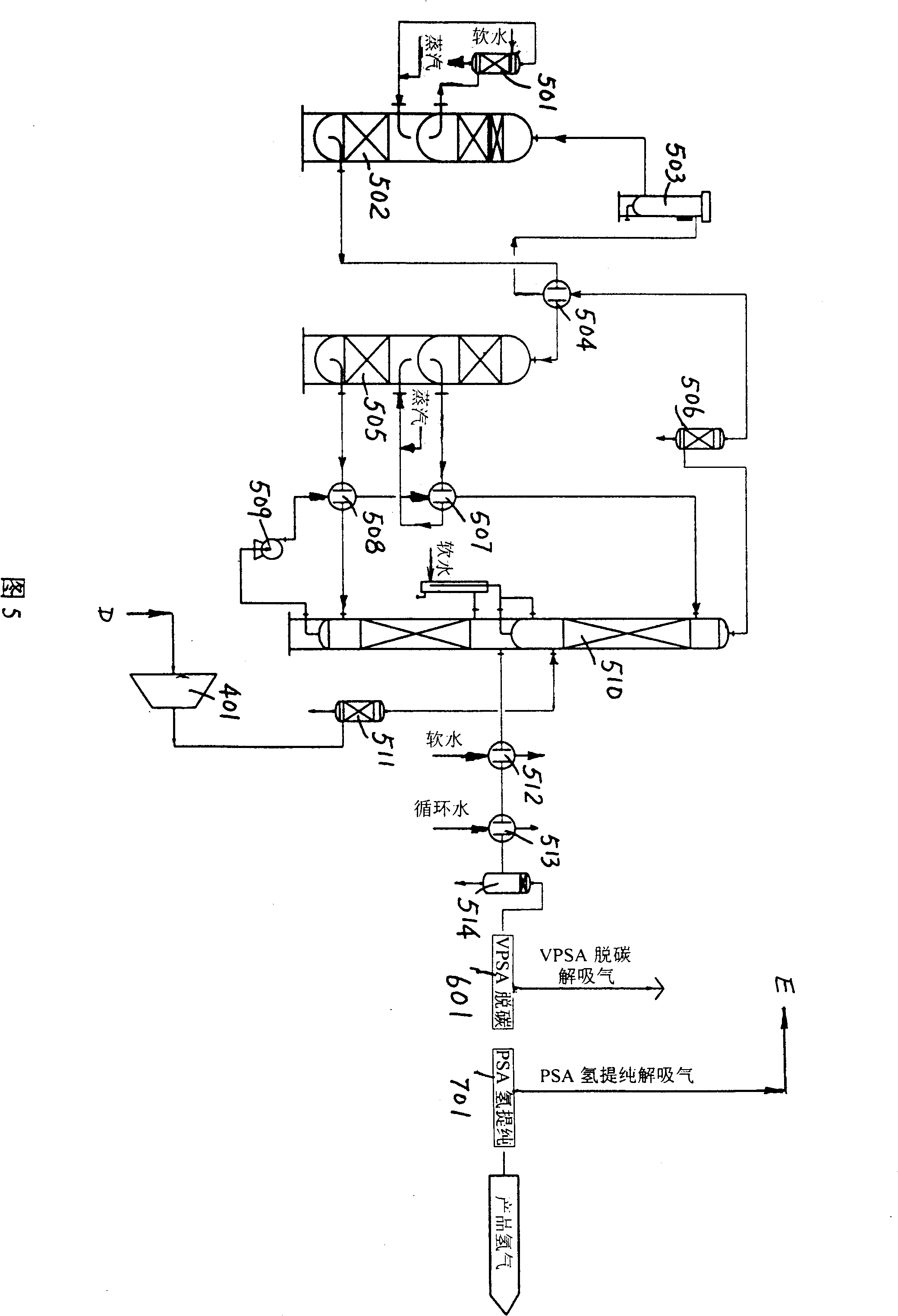

[0020] According to the following Figure 2 to Figure 5 , the process flow of small-scale high-efficiency coal gasification hydrogen production complete set of process equipment and techno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com