Universal white master batch and preparation method thereof

A technology of white masterbatch and mixture, which is applied in the field of general white masterbatch and its preparation, which can solve the problems such as the decline of impact performance, and achieve the effects of avoiding peeling, strong versatility and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

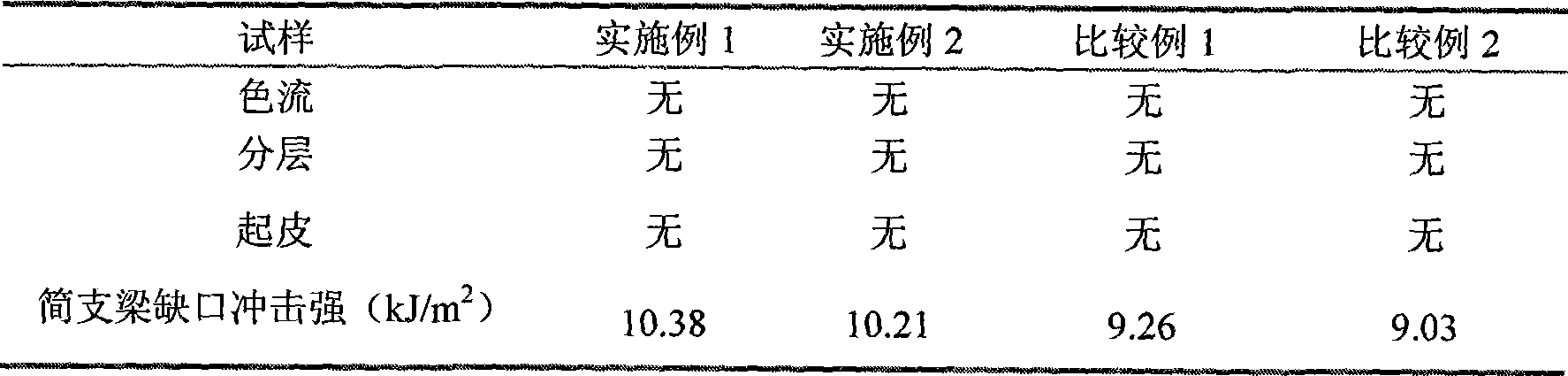

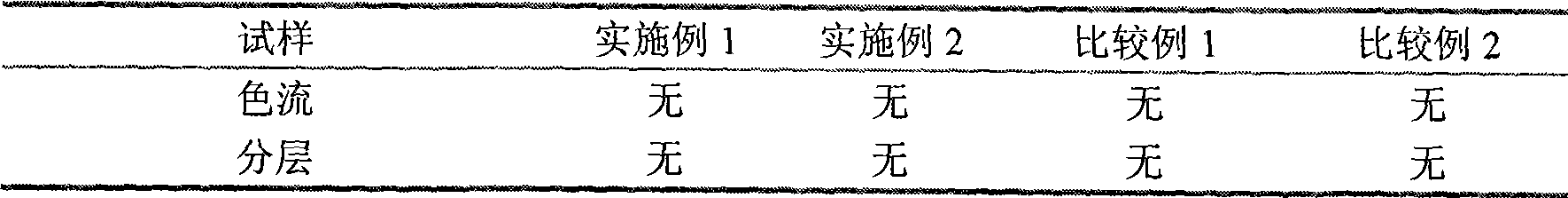

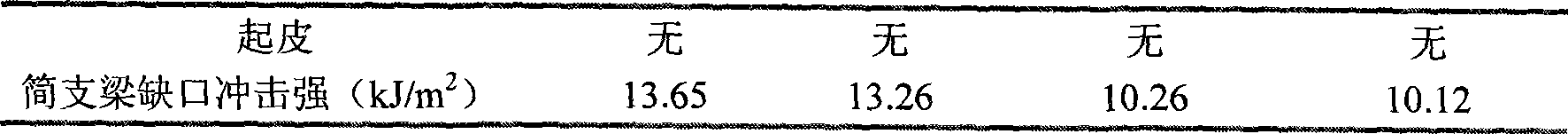

Embodiment 1

[0019] Under normal temperature and pressure, prepare 100kg micro-foaming universal white masterbatch, the weight of each component is: polyethylene-ethylene-butylene-styrene copolymer 13kg, ethylene-vinyl acetate copolymer 3.5kg, rutile titanium dioxide 74kg, 7.5kg of polyethylene wax, 1.2kg of zinc stearate, 0.5kg of ethylene bisstearamide, 10100.3kg of phenolic antioxidants, after proportioning each component, pre-mix each component in a mixer at a low speed (conventional premixing process in this industry) for 5 minutes, then high-speed mixing (conventional mixing process in this industry) for 15 minutes, and finally melt and blend the fully mixed materials in a twin-screw extruder, the temperature is controlled at 200 ° C, the screw speed The pigment is uniformly dispersed in the carrier resin by shearing and kneading of the screw at 200r / min, and then granulation, drying, packaging and other processes are carried out to obtain the color masterbatch of the present inventio...

Embodiment 2

[0021] Under normal temperature and pressure, prepare 100kg of foaming high-dispersion, impact-resistant, high-concentration general-purpose white masterbatch. The weight of each component is: polyethylene-ethylene-butylene-styrene copolymer 14kg, ethylene-vinyl acetate copolymer 3.5kg , titanium type titanium dioxide 48kg, polyethylene wax 7.5kg, zinc stearate 1.2kg, ethylene bis stearamide 0.5kg, phenolic antioxidant 10100.3kg, calcium carbonate 25kg, after proportioning each component, first Pre-mix the components in the mixer for 5 minutes at low speed, then mix at high speed for 20 minutes, and finally melt and blend the fully mixed materials with a twin-screw extruder. The temperature is controlled at 210°C, and the screw speed is 200r / min. The shearing and kneading of the pigment make the pigment evenly dispersed in the carrier resin, and then carry out granulation, drying, packaging and other processes to obtain the color masterbatch of the present invention.

[0022] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charpy impact strength | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

| Charpy notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com