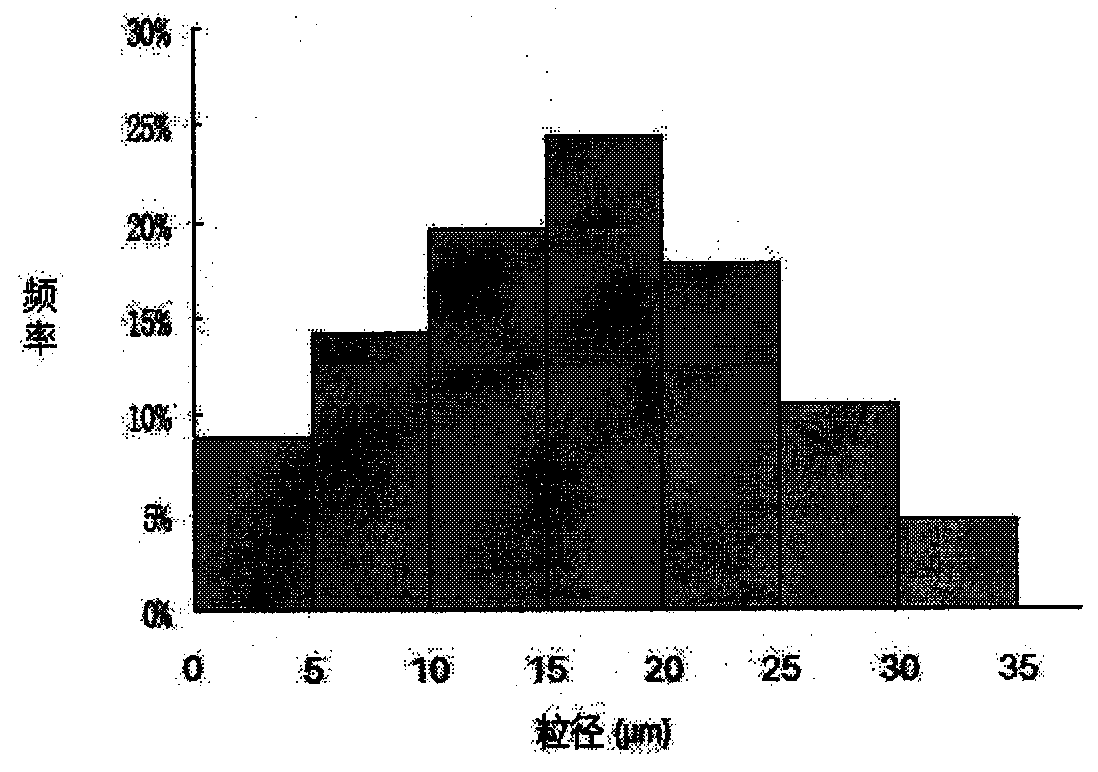

Curcumin glutin microsphere and preparation thereof

A technology of curcumin gelatin and preparation process, which is applied in the field of curcumin gelatin microspheres and its preparation, can solve the problems of no curcumin microspheres, etc., and achieve the effects of good fluidity, good dispersibility, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: prepare curcumin gelatin microspheres, the steps are as follows:

[0020] With liquid paraffin as the oil phase and Span80 as the emulsifier, slowly add 2 mL of curcumin-containing gelatin aqueous solution to 8 mL of liquid paraffin containing 2% Span80 at a temperature of 55 °C under 800 r / min electromagnetic stirring , wherein the mass concentration of gelatin is 20%, and the mass ratio of curcumin to gelatin is 1:20; stir for 30min to form a W / O emulsion, then cool down to 20°C, add 0.4mL of 25% glutaraldehyde solution, ice bath, Keep the temperature at 5-8°C, stir and solidify for 30 minutes, then put it in a refrigerator at 4-8°C to continue solidifying for 24 hours; pour out the upper oil phase, add isopropanol to dehydrate, filter with suction, and rinse several times with ether and isopropanol alternately , to obtain dry powder microspheres. It was determined that the drug loading was 2.22%, and the encapsulation efficiency was 27.50%.

Embodiment 2

[0021] Embodiment 2: prepare curcumin gelatin microspheres, the steps are as follows:

[0022] With liquid paraffin as the oil phase and Span80 as the emulsifier, at a temperature of 55°C, slowly add 2 mL of curcumin-containing gelatin aqueous solution to 8 mL of 1.5% Span80-containing liquid paraffin at a temperature of 55°C under 1000 r / min electromagnetic stirring , wherein the mass concentration of gelatin is 15%, and the mass ratio of curcumin to gelatin is 15:200; stir for 40min to form a W / O emulsion, then cool down to 20°C, add 0.4mL of 25% glutaraldehyde solution, ice bath, Keep the temperature at 5-8°C, stir and solidify for 25 minutes, and then put it in a refrigerator at 4-8°C to continue solidifying for 23.5 hours; pour the upper oil phase, add isopropanol to dehydrate, filter with suction, and rinse with ether and isopropanol alternately for several times Once, dry powdered microspheres were obtained. It was determined that the drug loading was 4.44%, and the en...

Embodiment 3

[0023] Embodiment 3: prepare curcumin gelatin microspheres, the steps are as follows:

[0024] With liquid paraffin as the oil phase, Span80 as the emulsifier, at a temperature of 55°C, slowly add 2mL of aqueous gelatin solution containing curcumin to 8mL of liquid paraffin containing 1% Span80 at a temperature of 55°C under electromagnetic stirring, wherein, The mass concentration of gelatin is 10%, and the mass ratio of curcumin and gelatin is 1:10; stir to form a W / O emulsion, then cool down to 20°C, add 0.4mL of 25% glutaraldehyde solution, and keep the temperature at 5 Stir and solidify at ~8°C for 35 minutes, then put it in a refrigerator at 4-8°C to continue curing for 24.5 hours; pour the upper oil phase, add isopropanol to dehydrate, filter with suction, rinse several times with ether and isopropanol alternately, and dry Powdered microspheres. It was determined that the drug loading was 7.6%, and the encapsulation efficiency was 71.50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com