Active principle of sarsaparilla and extracting method thereof

An active ingredient and a technology for sarsaparilla, which are applied to the extraction and purification method of sarsaparilla effective ingredients and the field of extract products thereof, can solve the problems of difficult production process requirements, low content of active ingredients, cumbersome process, etc., and achieve low cost and transfer efficiency. The effect of improving the rate and content and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 The extraction process test of the effective parts of Rattan jinganga

[0034] (1) use the ethanol reflux extraction method to carry out the experiment, adopt L 9 (3 4 ) Orthogonal experiment method to investigate the process parameters of ethanol reflux extraction of total flavonoids of Smilax, ethanol concentration in total saponins, ethanol dosage (multiple of Smilax weight) and extraction time times, and adopt UV-visible spectrophotometry to extract The contents of total flavonoids and total saponins were determined, and the comparison and analysis were carried out with the contents of total flavonoids, total saponins and the yield of dry paste as indicators. The results are shown in Table 1, Table 2 and Table 3.

[0035] Table 1 Level table of experimental factors

[0036]

[0037] Table 2 Orthogonal experiment design and result analysis

[0038]

[0039]

[0040] Table 3 Analysis of variance of total flavonoids

[0041]

[0042] F0.05 (2...

Embodiment 2

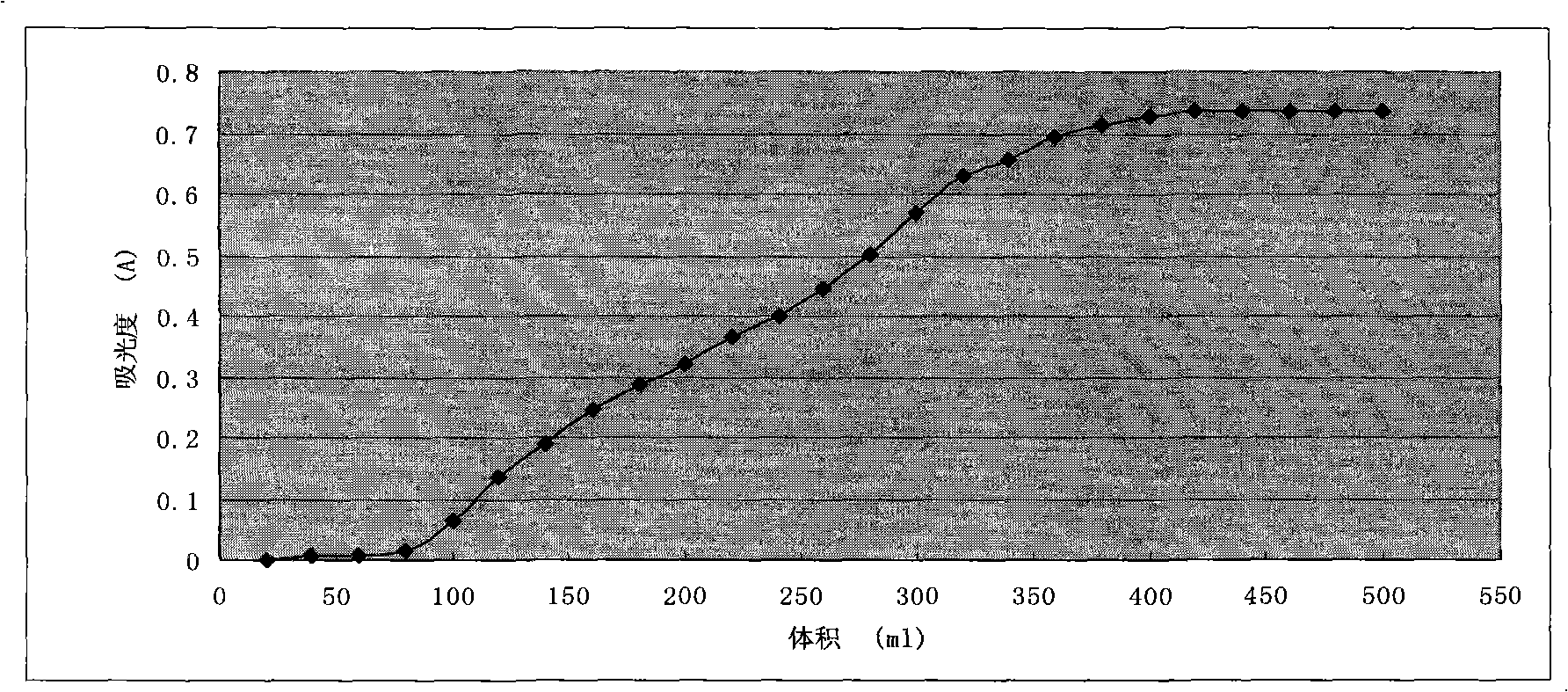

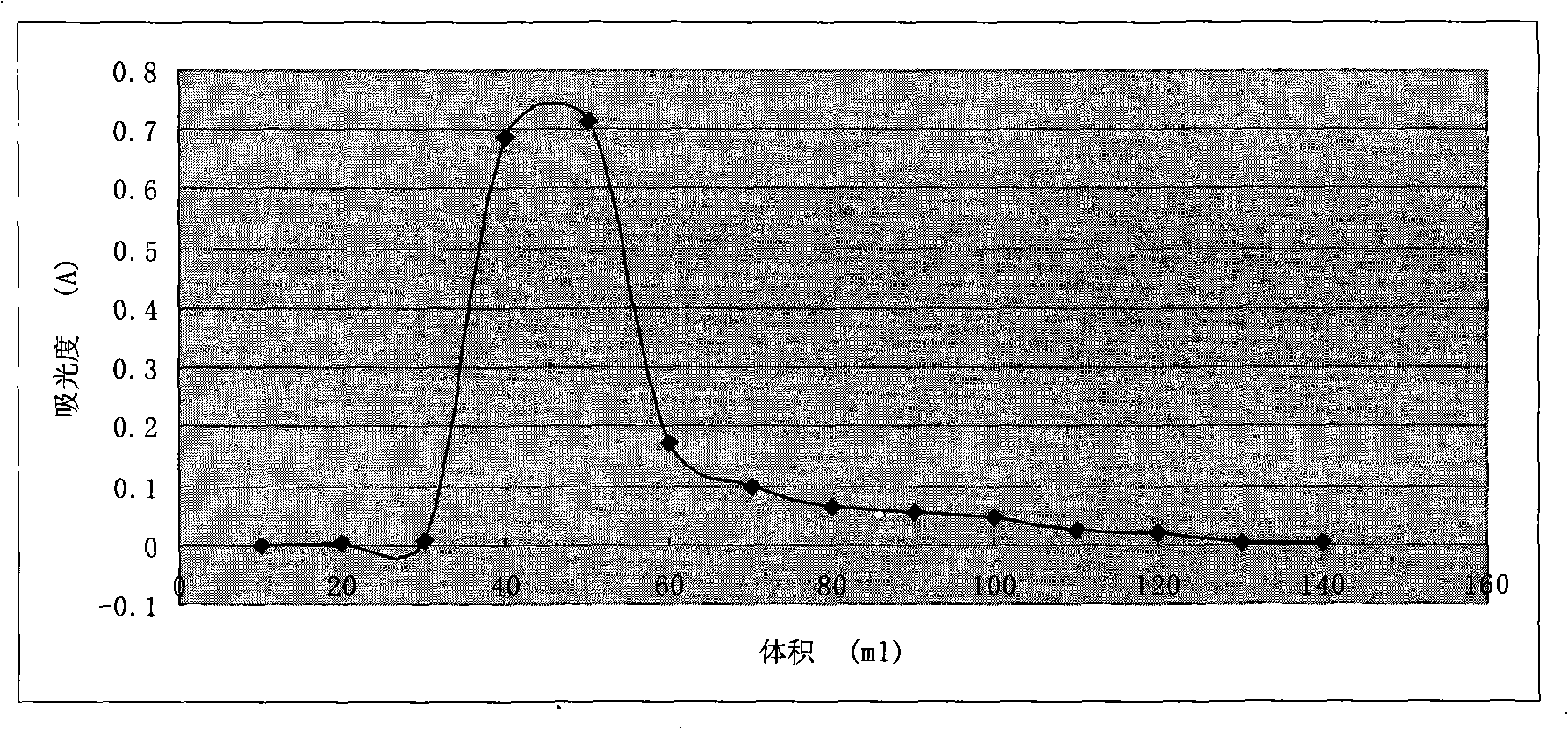

[0053] Example 2 The macroporous resin purification process experiment of the effective part group of jingangatana

[0054] The sarsaparilla extract that extracts with aforementioned optimal extraction condition is carried out following experiment:

[0055](1) Screening experiment of macroporous resin

[0056] Resin source: D101 resin (Tianjin Haiguang Chemical Co., Ltd.), AB-8, HPD100 resin (Hebei Baocang Co., Ltd.).

[0057] The screening results of the resin are shown in Table 7 and Table 8.

[0058] Table 7 Measurement results of static saturation adsorption and desorption of three resins

[0059]

[0060] Table 8 Dynamic screening results of three macroporous resins

[0061]

[0062] The test results show that: D101 and HPD100 macroporous resins have better specific adsorption capacity and elution rate for total flavonoids, total saponins and total tannins of Smilax. However, D101 type macroporous resin has lower price, better effect and higher safety. Therefore...

Embodiment 3

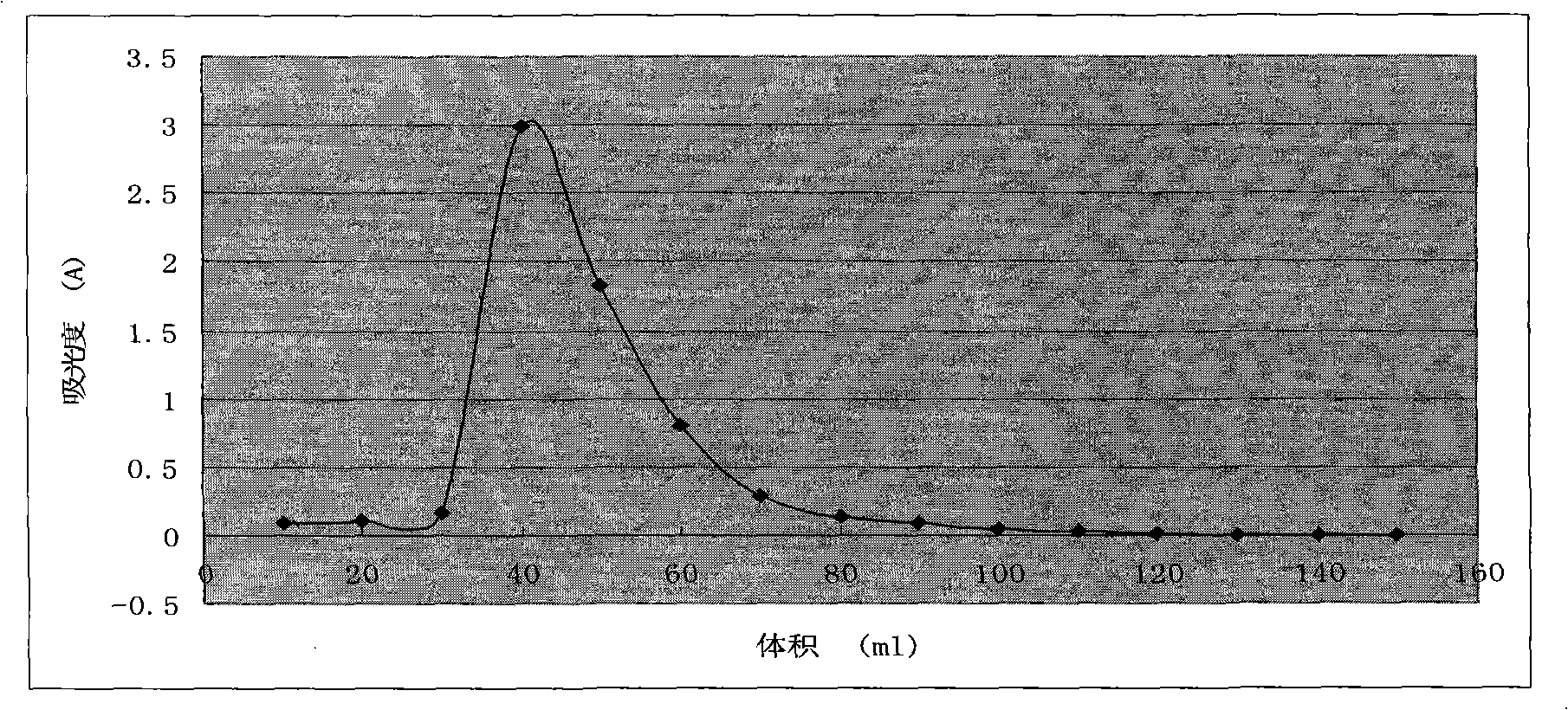

[0099] Embodiment 3 Pilot scale scale-up experiment

[0100] Take sarsaparilla decoction pieces, add 8 times the amount of 60% ethanol to heat and reflux extraction for 3 times, the first time for 2 hours, the second and third times for 1 hour each, combine the filtrates, recover the ethanol under reduced pressure to a certain volume, and suction filter to obtain the sample drug solution.

[0101] Soak 20kg of pharmaceutical-grade D101 macroporous resin with an appropriate amount of ethanol, wet-pack the column, and prepare it for later use.

[0102] Adsorption is carried out at a flow rate of 2BV / h, and the resin bed diameter-to-height ratio is 1:8. After the adsorption is completed, use 3BV of distilled water to elute at a flow rate of 2BV / h until the Molish reaction is negative, and then use 5 times the resin column 70% ethanol by volume, eluted at a flow rate of 2BV / h, and collected the eluate. The eluent was concentrated to a relative density of 1.05, and then spray-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com