Device and method for controlling length of electric arc

An arc length and control method technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of inability to accurately reflect the arc length, and achieve strong anti-interference ability, simple parameter setting, and simple circuit structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

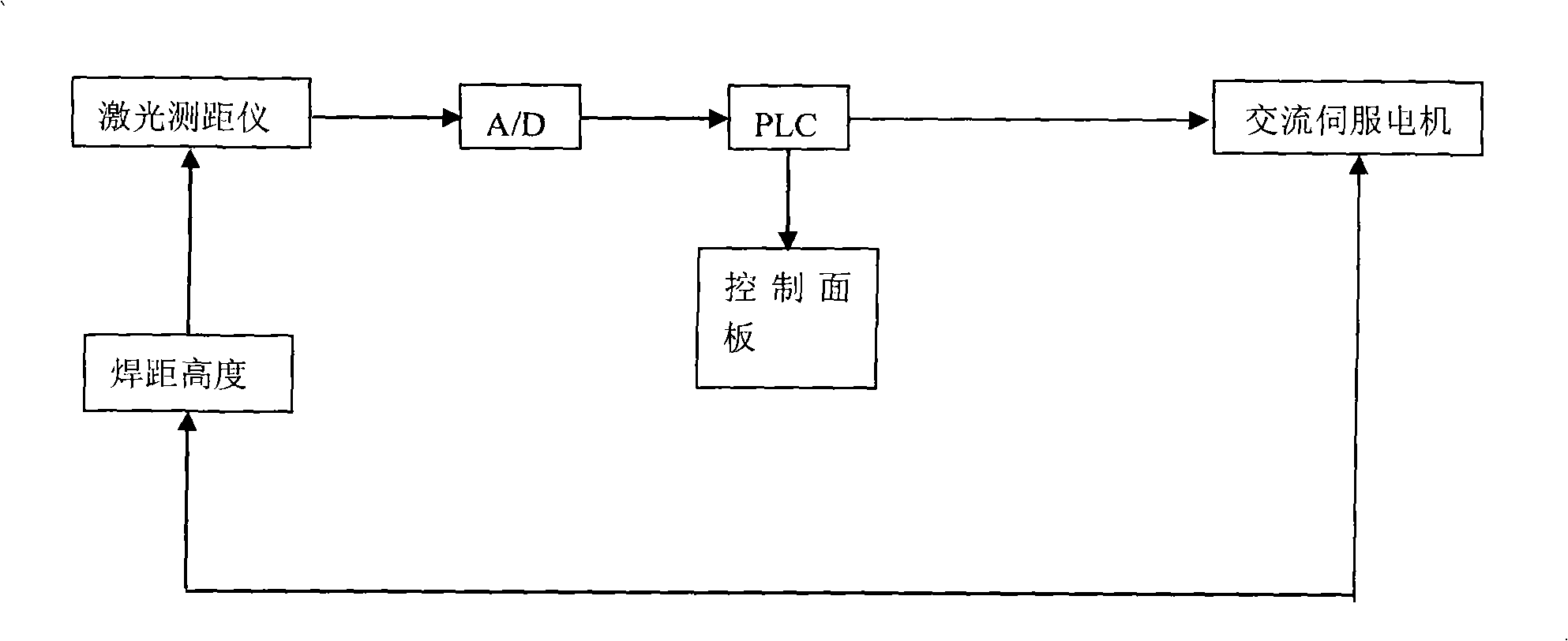

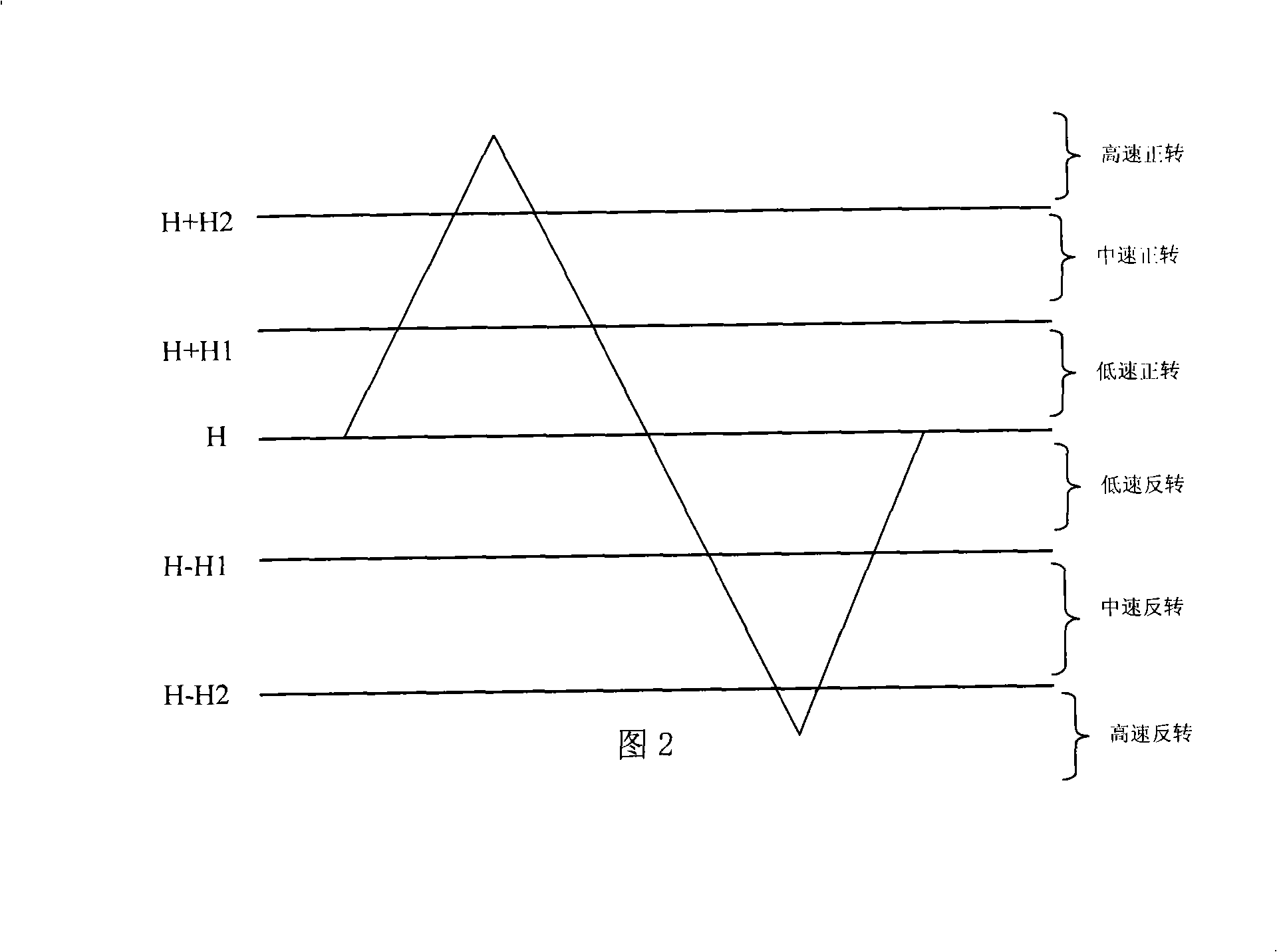

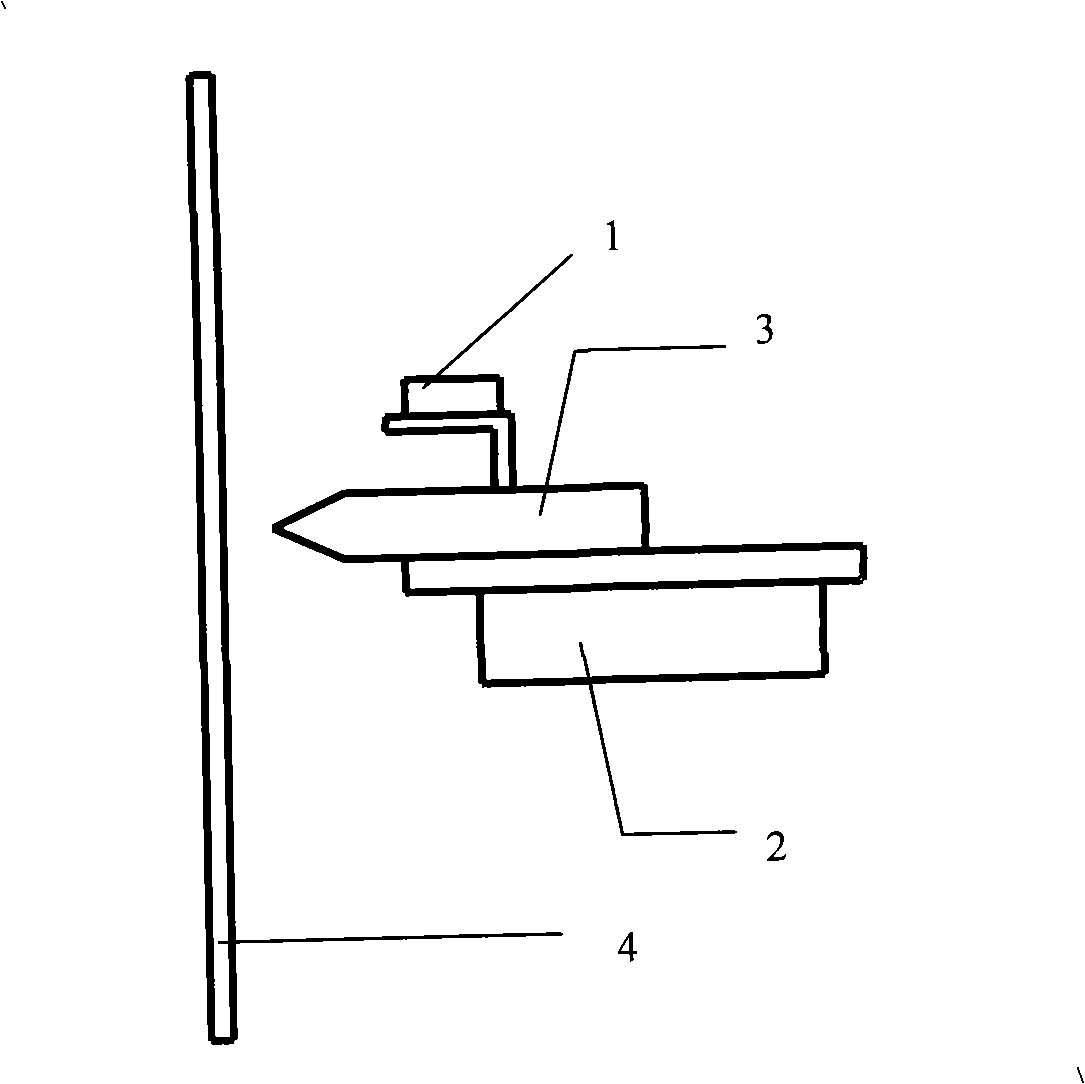

[0023] The device includes a laser range finder 1, an AC servo motor 2, an A / D conversion module, a PLC (programmable logic controller) control unit and a control panel connected with the PLC control unit. The laser range finder 1 is installed on the welding torch frame of the welding torch 3 so that it moves synchronously with the welding torch 3 . Its function is to collect the distance between the workpiece 4 and the laser rangefinder 1. This distance can directly reflect the welding arc length (ie welding height), and the arc length is transmitted to the PLC control unit through the A / D conversion module in the form of voltage. After processing in the PLC control unit, compare the distance with the set welding distance height value to confirm the direction of rotation. By changing the pulse frequency of the PLC to change the speed of the AC servo motor 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com