Fiber reinforced composite material and preparation thereof

A composite material and fiber-reinforced technology, applied in the field of composite materials, can solve the problems of electromagnetic shielding effect degradation and hindering electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

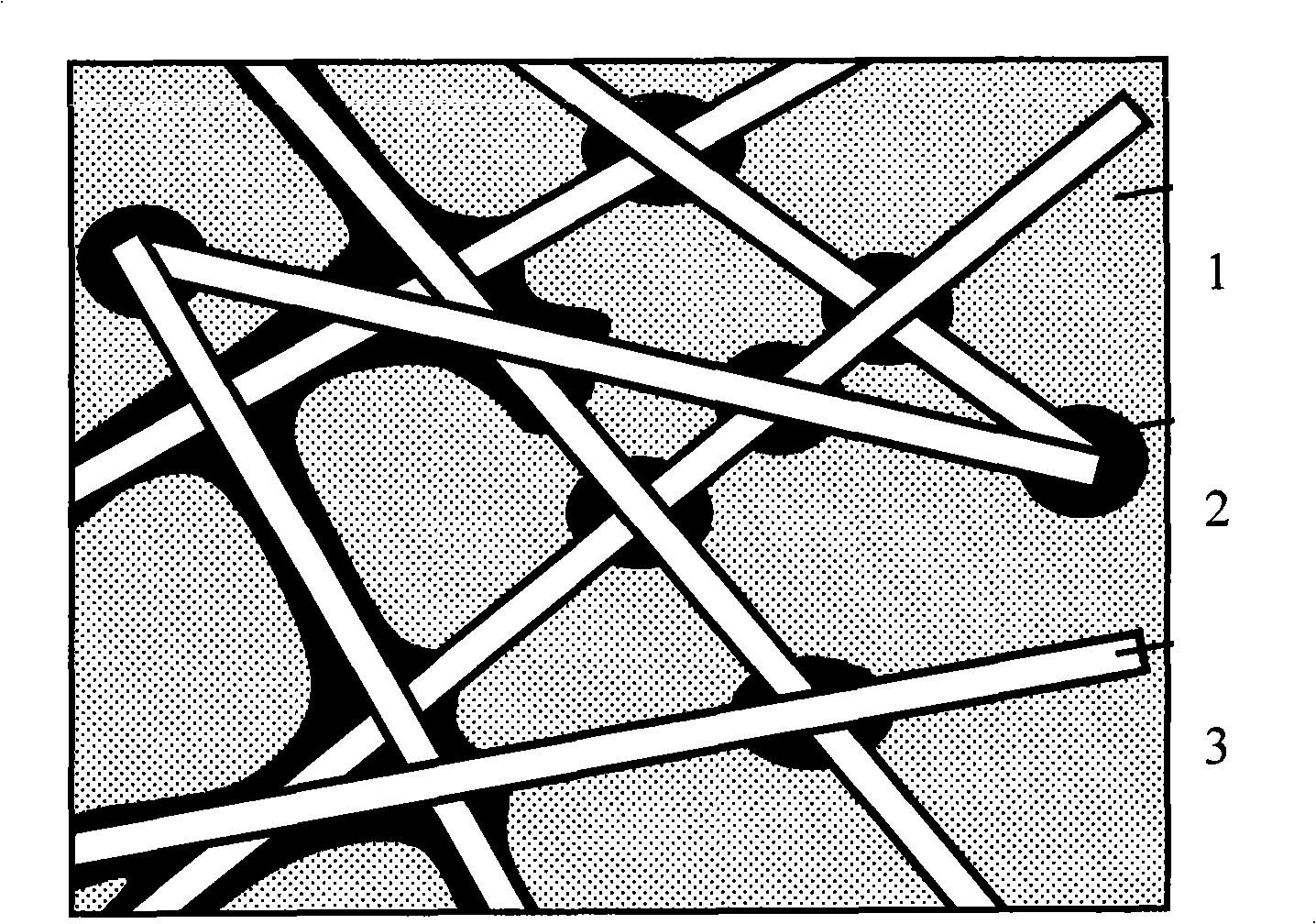

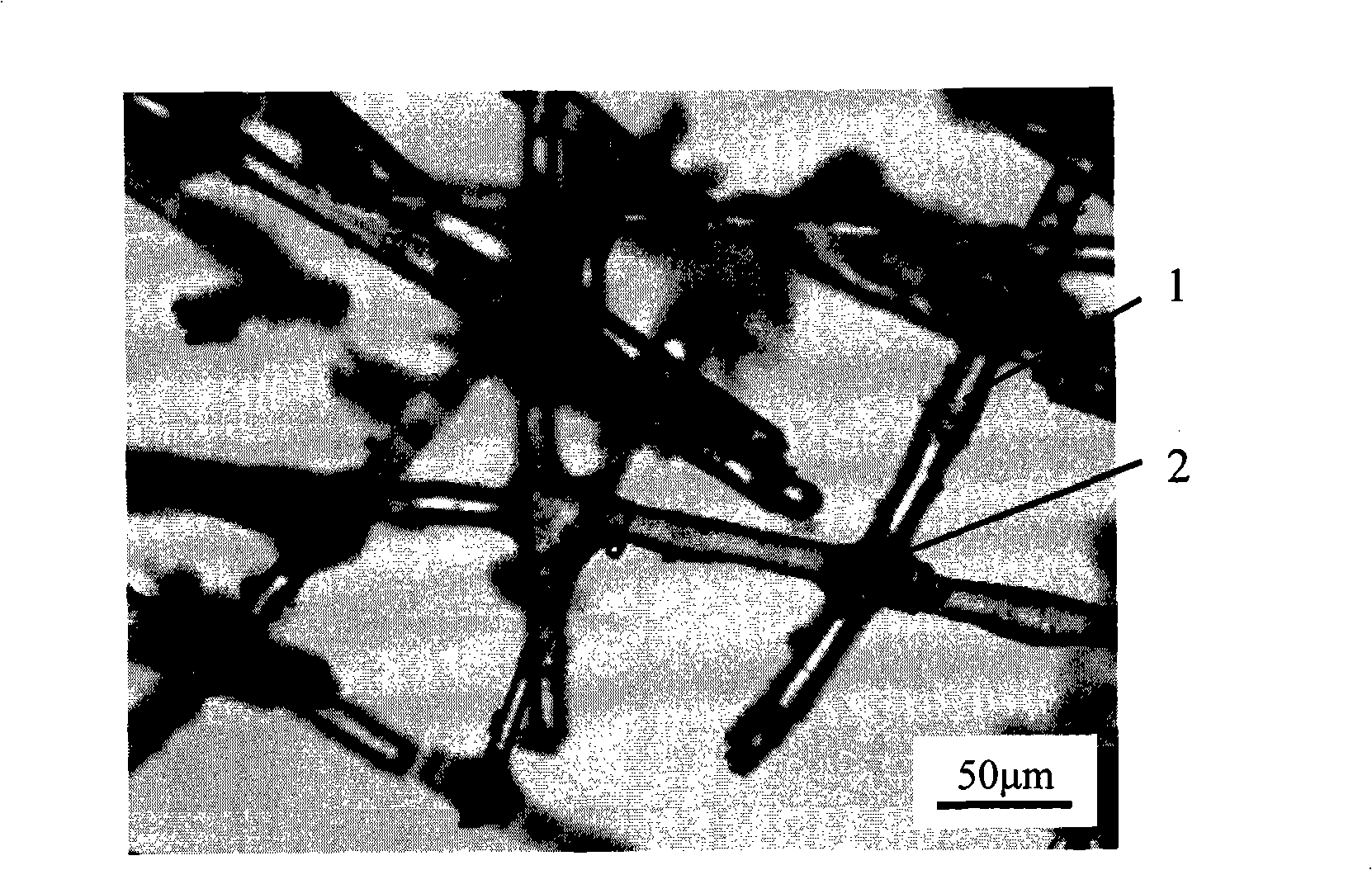

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The acrylonitrile-butadiene-styrene copolymer was melt-extruded at 220°C in a single-screw extruder equipped with a right-angle head at the head position, and a continuous copper fiber bundle with a diameter of 30 μm passed through the right-angle head along the direction perpendicular to the extruder. Traction in the outgoing direction, after water-cooled drying and pelletizing, obtain the master batch containing 85wt% copper fiber content, then acrylonitrile-butadiene-styrene copolymer, the above-mentioned copper fiber master batch and particle diameter are tin-lead alloy powder ( The lead content is 35wt%, and the melting point is 183°C). After weighing according to the weight ratio of 74 / 20 / 6, it is added to a twin-screw extruder and melted and extruded at 220°C. After the extruded product is pelletized and dried, it is injection molded at 230°C . The volume resistivity of the obtained material is 8.36×10 -1 ohm.cm.

Embodiment 2

[0035] Acrylonitrile-butadiene-styrene copolymer, copper fiber with a diameter of 30 μm and tin-lead alloy powder with an average diameter of 35 μm (lead content 35wt%, melting point is 183 ° C) were weighed according to the mass ratio 61 / 11 / 28 After that, it is added to a twin-screw extruder and melted and extruded at 220°C. After the extrudate is pelletized and dried, it is injection molded at 230°C. The volume resistivity of the obtained material is 4.55×10 -2 ohm.cm.

Embodiment 3

[0037] With the method of Example 1, 85 wt% copper fiber reinforced polypropylene masterbatch was prepared at 220°C. Then polypropylene, masterbatch and tin-copper alloy powder (copper content 0.7wt%, fusing point 227 ℃) with particle diameter of 35 μm are prepared composite material with embodiment 1 by weight ratio 64 / 30 / 6, and wherein extruding temperature is 220 °C, and the injection temperature is 240 °C. The volume resistivity of the obtained material is 6.35×10 -2 ohm.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com