Electrochemistry mixing capacitor base on water system (acid) electrolyte

A hybrid capacitor and electrolyte technology, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problem of less electrolyte solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

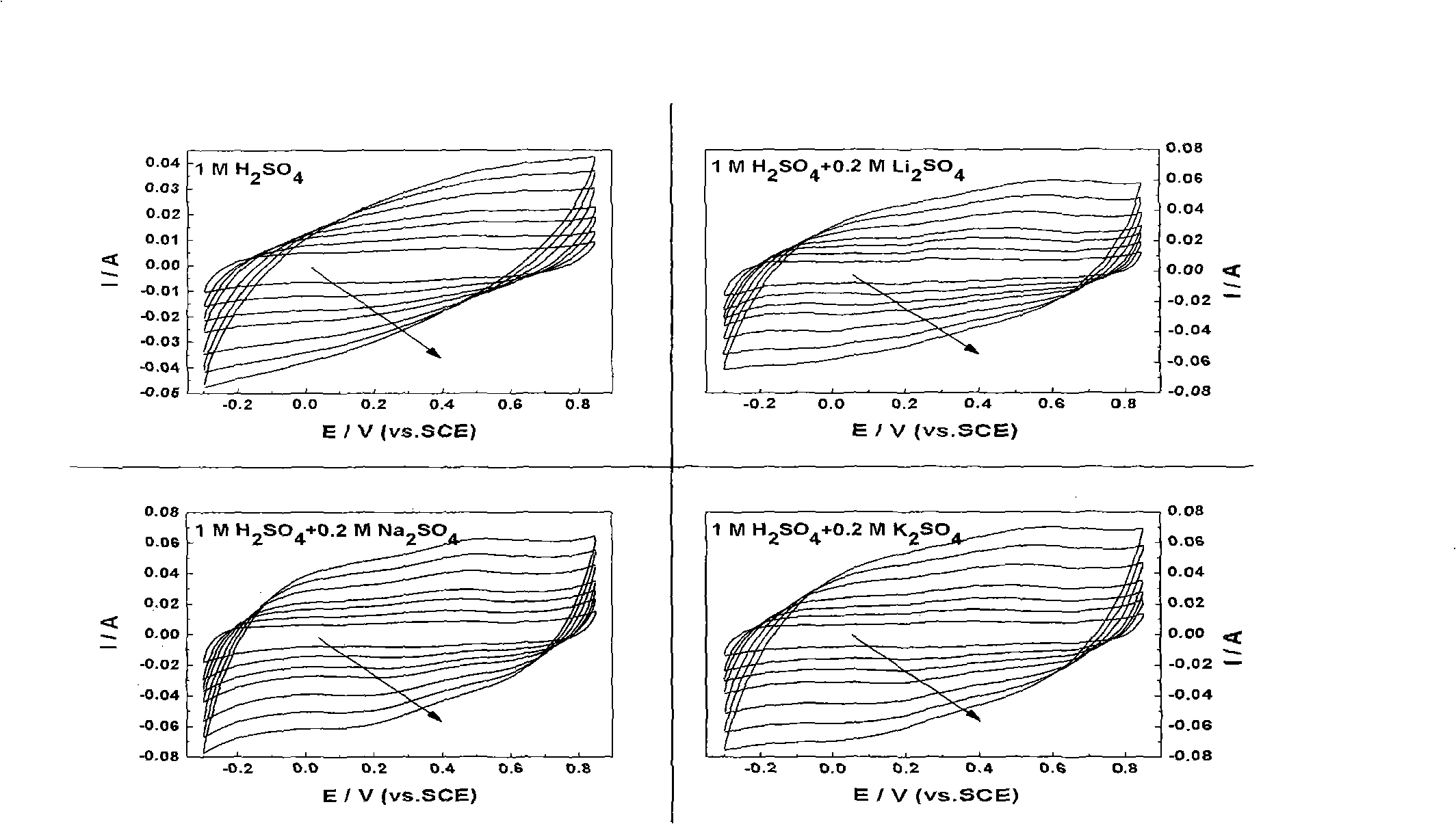

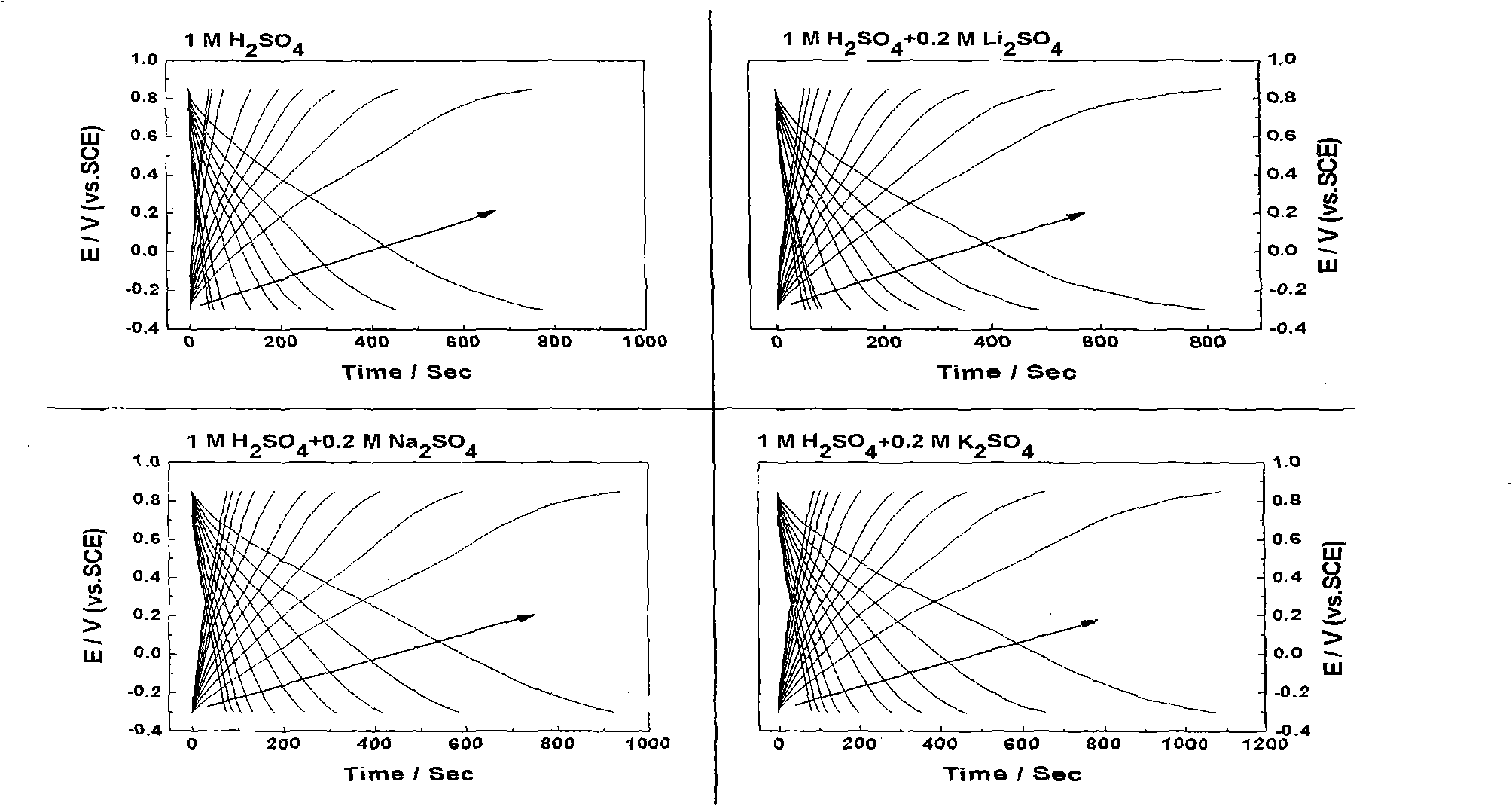

[0014] Prepare a concentration of 1M H 2 SO 4 Aqueous solution and containing concentration of 1M H 2 SO 4 with 0.2MLi 2 SO 4 、1M H 2 SO 4 with 0.2M Na 2 SO 4 and 1M H 2 SO 4 with 0.2M K 2 SO 4 mixed solution as a supporting electrolyte.

experiment example 1

[0016] Mix the obtained activated carbon with acetylene black and PTFE at a ratio of 8.5:1.0:0.5 (mass ratio), add a little deionized water dropwise after grinding to make it evenly mixed, and press it on the carbon electrode under a pressure of 12MPa to make a working electrode. The area is 3.14cm 2 . A three-electrode system was used to test the performance of electrode materials. A saturated calomel electrode (SCE) was selected as the reference electrode, and a platinum electrode (1cm×1cm) was used as the counter electrode. 2 SO 4 , 1MH 2 SO 4 +0.2M Li 2 SO 4 、1M H 2 SO 4 +0.2M Na 2 SO 4 with 1M H 2 SO 4 +0.2M K 2 SO 4 The solution is the supporting electrolyte. The above-mentioned three electrodes were immersed in the above-mentioned three kinds of electrolytes to form a three-electrode system, and the performance test of the capacitor was carried out. All tests were carried out at room temperature, and the electrochemical behavior was characterized by a CHI...

experiment example 2

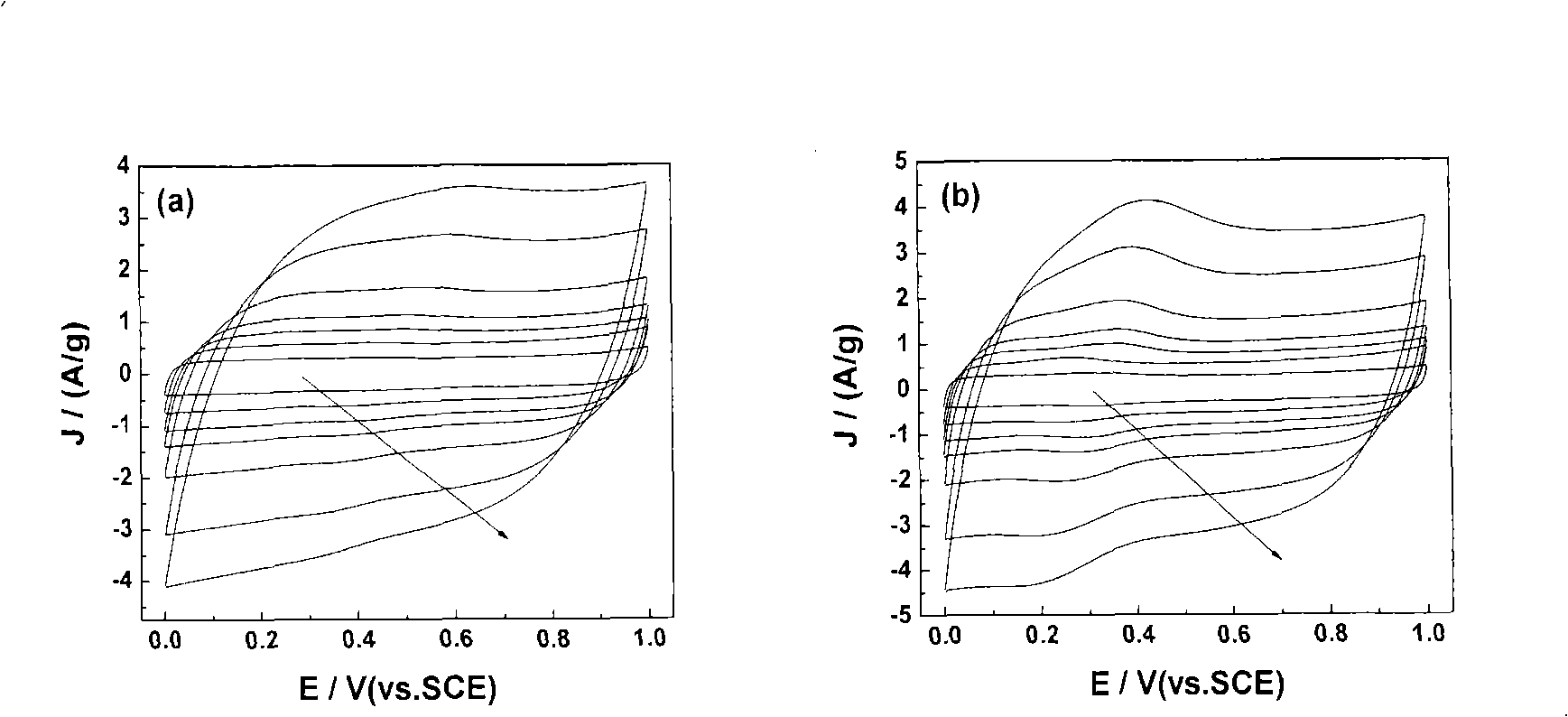

[0018] According to the method for preparing the working electrode in Experimental Example 1, prepare two working electrodes as the positive and negative electrodes respectively, wherein the ratio of the activated carbon mass of the positive electrode to the negative electrode is 1:1, immersed in the above-mentioned electrolyte to form a simulated capacitor, and simulate Capacitor performance test. All tests were carried out at room temperature, and the electrochemical behavior was characterized by a CHI660B electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.). The cyclic voltammetry and constant current charge and discharge diagrams of the simulated capacitors are shown in image 3 and 4 As shown, the specific capacitance and specific energy density of the assembled hybrid capacitors are also shown in Table 2.

[0019] Table 1: Indicates the single-electrode specific capacitance of the prepared electrode materials

[0020]

[0021] Table 2: Indicates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com