Three-dimensional strain NMOS integrated device and preparation method thereof

An integrated device and three-dimensional technology, which is applied in the field of three-dimensional strained NMOS integrated devices and its production, can solve the problems of low speed of three-dimensional integrated devices, achieve the effects of ensuring AC and DC electrical performance, shortening interconnection lines, and reducing process steps

Inactive Publication Date: 2011-01-05

XIDIAN UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

One of the purposes of the present invention is to provide a three-dimensional strained NMOS integrated device, and the second purpose is to provide a method for manufacturing a three-dimensional strained NMOS integrated device to solve the problem of low speed of existing three-dimensional integrated devices

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

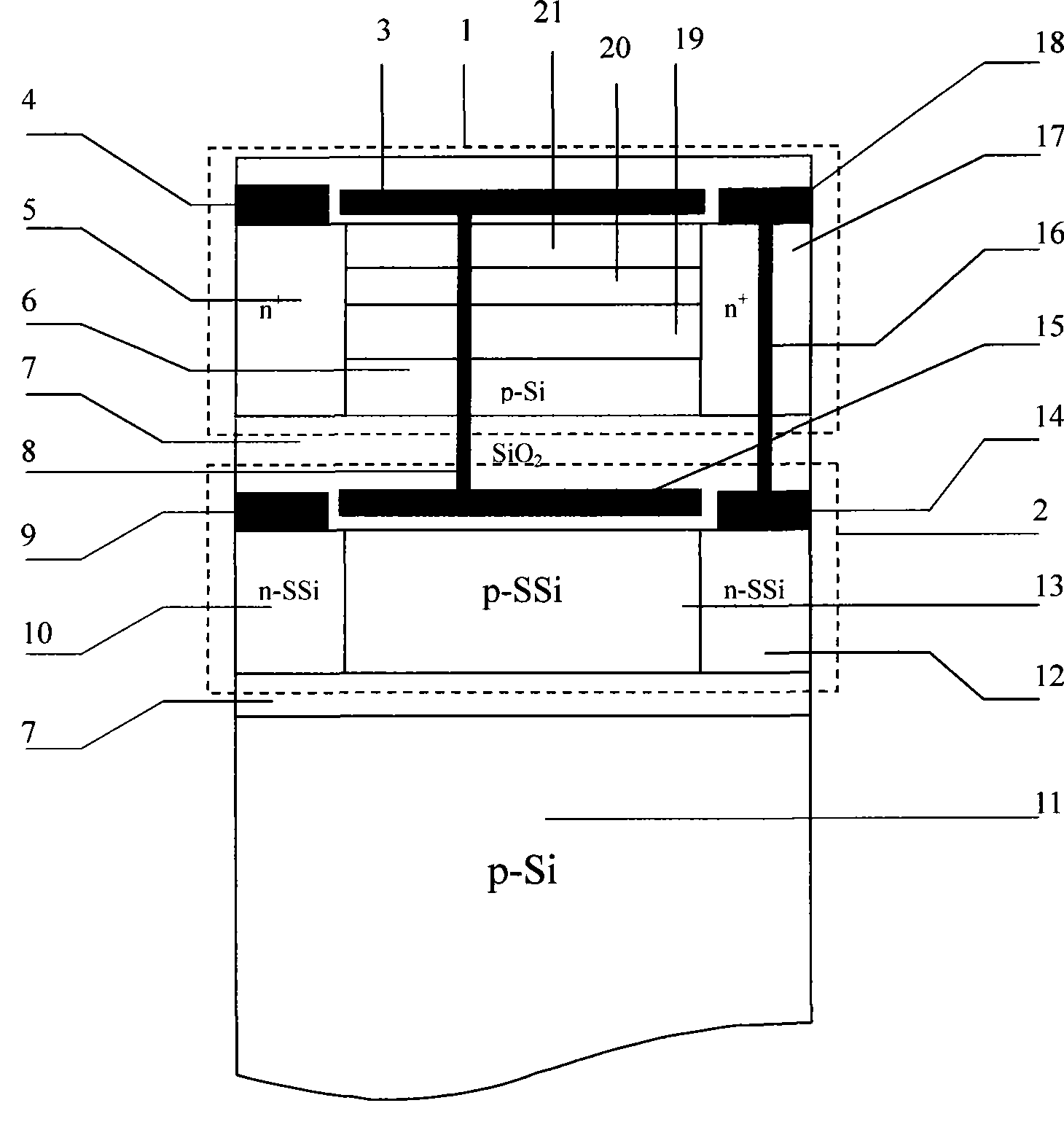

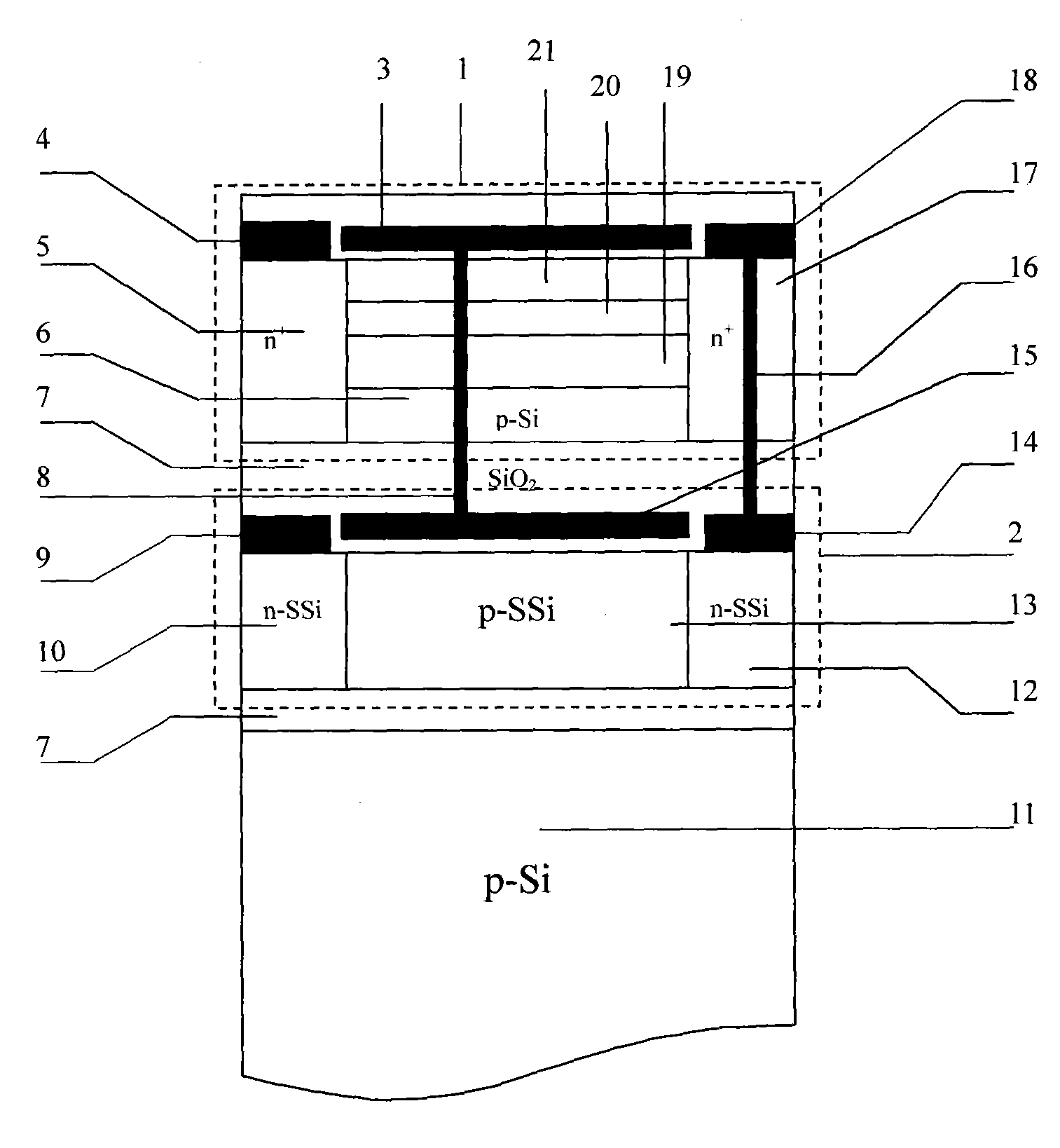

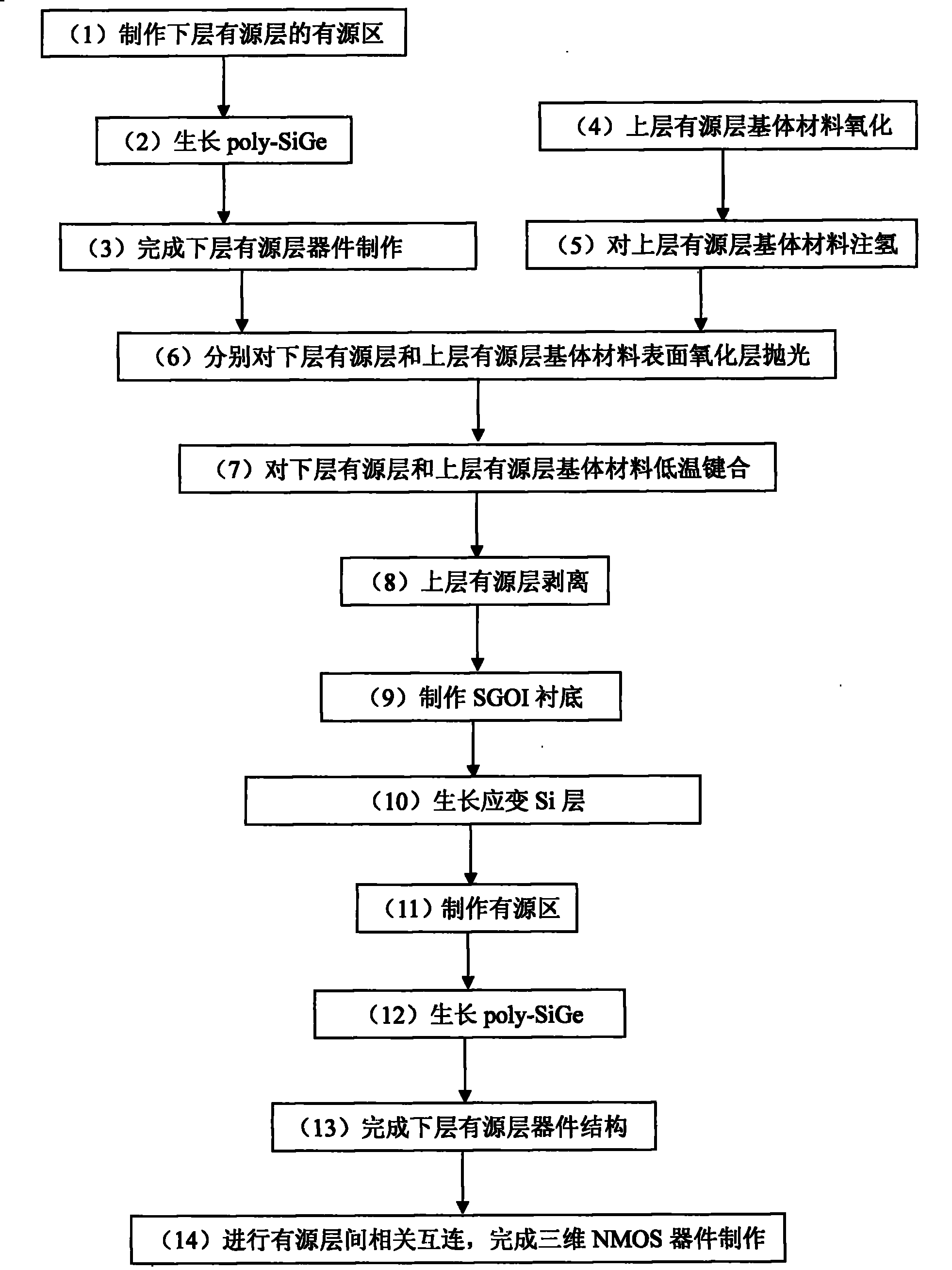

The invention discloses a 3D strained NMOS integrated device and a manufacturing method thereof, relates to the technical field of microelectronics, and mainly solves the problem of low speed of the existing 3D integrated circuit. The proposal is that an SSOI substrate and an SGOI substrate are employed to construct two active layers of a new 3D integrated device; wherein, the lower active layer is the SSOI substrate and is made into strained Si NMOSFET with a poly-SiGe gate by utilizing the characteristic of high electron mobility of a strained Si material in the SSOI substrate; the upper active layer is the SGOI substrate on which a layer of strained Si grows and is made into strained Si surface channel NMOSFET with the poly-SiGe gate; the lower active layer and the upper active layer are connected by an interconnection line to form the 3D strained NMOS integrated device with a conducting channel of 65nm to 130nm. Compared with the existing 3D integrated devices, the 3D strained NMOS integrated device manufactured by the manufacturing method has the advantages of high speed and good performance, and can be applied to manufacturing large-scale and high-speed 3D CMOS integrated circuits.

Description

Three-dimensional strained NMOS integrated device and its fabrication method technical field The invention belongs to the technical field of semiconductor integrated circuits, and in particular relates to a three-dimensional strained NMOS integrated device and a manufacturing method thereof. Background technique Since the 1960s, the feature size of integrated circuits has been continuously reduced following Moore's Law, and the integration and performance of chips have been continuously improved. Entering the deep submicron era, the interconnection of devices inside the chip becomes more and more complex. Therefore, the influence of the delay time caused by the parasitic resistance and parasitic capacitance of the interconnection on the performance of the circuit becomes more and more prominent. Studies have shown that after the feature size of the device is less than 250nm, the R-C delay caused by conventional metal wiring will dominate the entire circuit delay, which re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L27/12H01L21/84

Inventor 胡辉勇张鹤鸣戴显英宣荣喜宋建军舒斌赵丽霞

Owner XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com