Hot-rolled ultra soft high-carbon steel plate and process for production thereof

A technology of hot-rolled steel plates and manufacturing methods, which is applied in the direction of manufacturing tools, metal rolling, heat treatment furnaces, etc., can solve problems such as difficult dissolution of carbides and reduced quenching strength, and achieve processing procedures, low costs, and uniformity Coarsening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

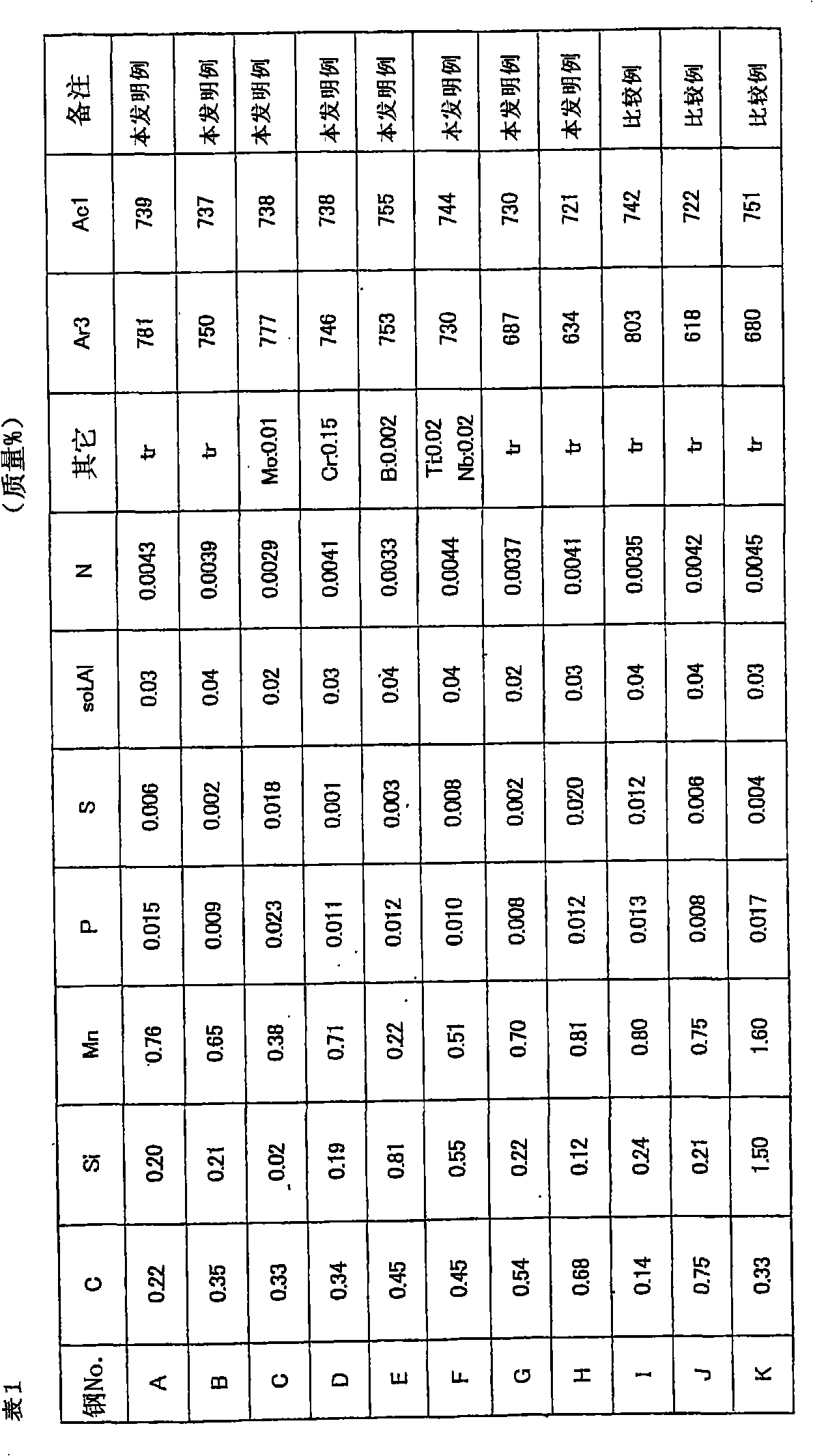

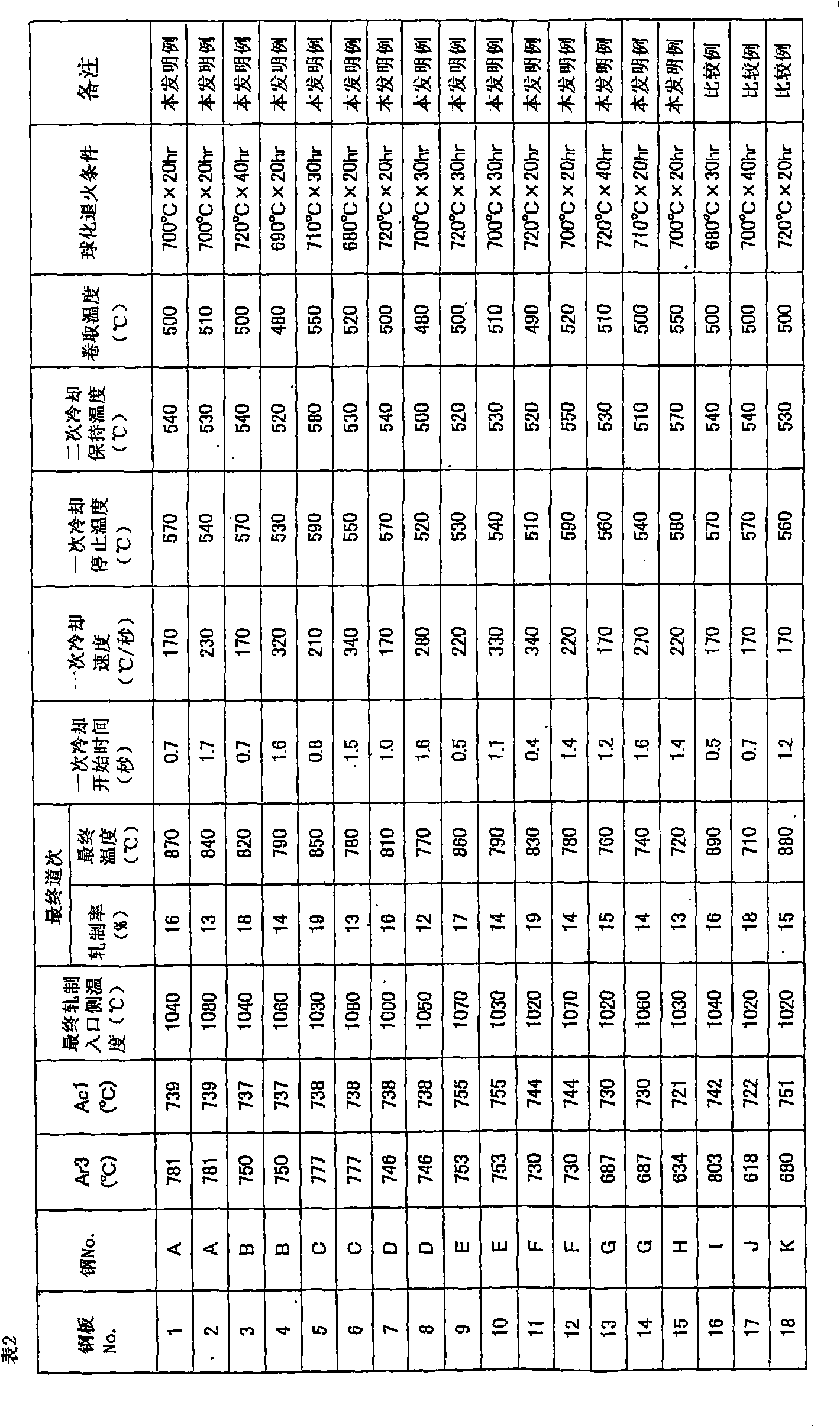

[0106] The steel having the chemical composition shown in Table 1 was continuously cast, and the obtained slab was heated to 1250°C, and hot rolled and annealed under the conditions shown in Table 2 to produce a hot rolled sheet with a thickness of 3.0mm. steel plate.

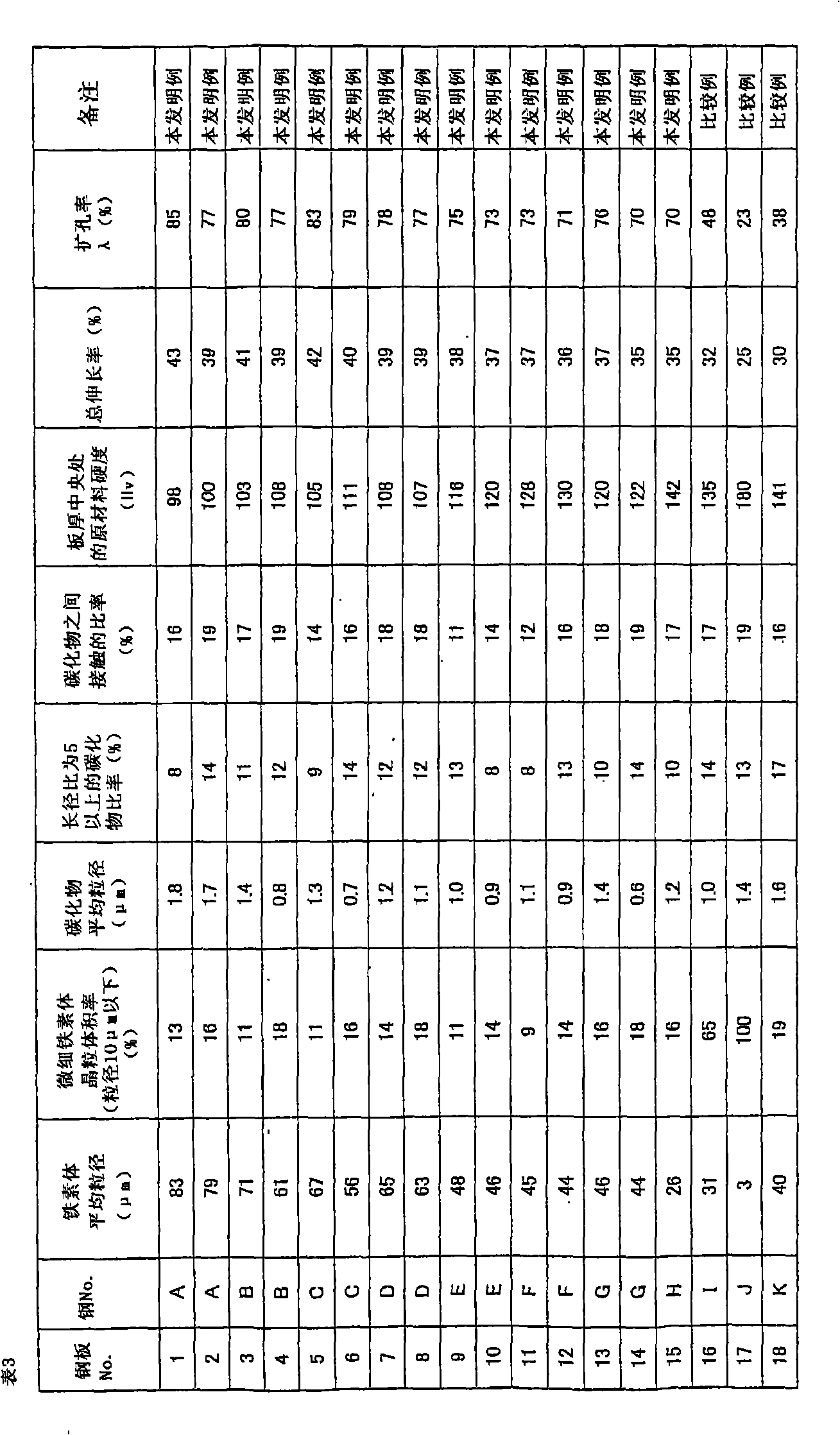

[0107] Next, a sample is taken from the hot-rolled steel sheet obtained above, and the average ferrite grain size, fine ferrite grain volume ratio, average carbide grain size, carbide aspect ratio, and contact between carbides are measured. Ratio, and determine the raw material hardness, total elongation and hole expansion rate for performance evaluation. The respective measurement methods and conditions are as follows.

[0108] [Average grain size of ferrite]

[0109] Using the cutting method described in JIS G 0552, it is measured from the optical microscope structure in the thickness section of the sample. In addition, the average grain size is set to an average value of 3000 or more ferrite crystal grain...

Embodiment 2

[0133] Steels having the chemical composition shown in Table 4 were continuously cast, and the resulting slabs were heated to 1250°C, hot-rolled and annealed under the conditions shown in Table 5, to produce hot-rolled steel sheets with a thickness of 3.0 mm .

[0134] Next, samples were taken from the hot-rolled steel sheet obtained above, and the average ferrite grain size, fine ferrite grain volume ratio, carbide average grain size, carbide aspect ratio, and contact ratio between carbides were measured. Ratio, and determine the raw material hardness, total elongation and hole expansion rate for performance evaluation. The respective measurement methods and conditions are the same as in Example 1.

[0135] Table 6 shows the results obtained by the above measurements.

[0136] In Table 6, steel plates No. 19 to 29 have chemical components within the scope of the present invention, and have an average ferrite particle size, a fine ferrite grain volume ratio (grain size below...

Embodiment 3

[0142] Steels having the chemical composition shown in Table 1 were continuously cast, and the resulting slabs were heated to 1250°C, hot-rolled and annealed under the conditions shown in Table 7, to produce hot-rolled steel sheets with a thickness of 3.0mm .

[0143] Next, samples were taken from the hot-rolled steel sheet obtained above, and the average ferrite grain size, fine ferrite grain volume ratio, carbide average grain size, carbide aspect ratio, and contact ratio between carbides were measured. Ratio, and determine the raw material hardness, total elongation and hole expansion rate for performance evaluation. The respective measurement methods and conditions are the same as in Example 1.

[0144] Table 8 shows the results obtained above.

[0145] In Table 8, the production conditions of steel plates No.31 to 47 are within the scope of the present invention, and have an average ferrite particle size, fine ferrite grain volume ratio (grain size of 20 μm or less), av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com