Intravenous anesthetics 2,6-diisopropyl phenol microemulsion composition and method of making the same

A technology of diisopropylphenol and composition, applied in the field of intravenous anesthetics, can solve the problems that are not conducive to improving patient compliance and reducing pain, and achieve good emulsification effect, low requirements for storage conditions, and reasonable price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

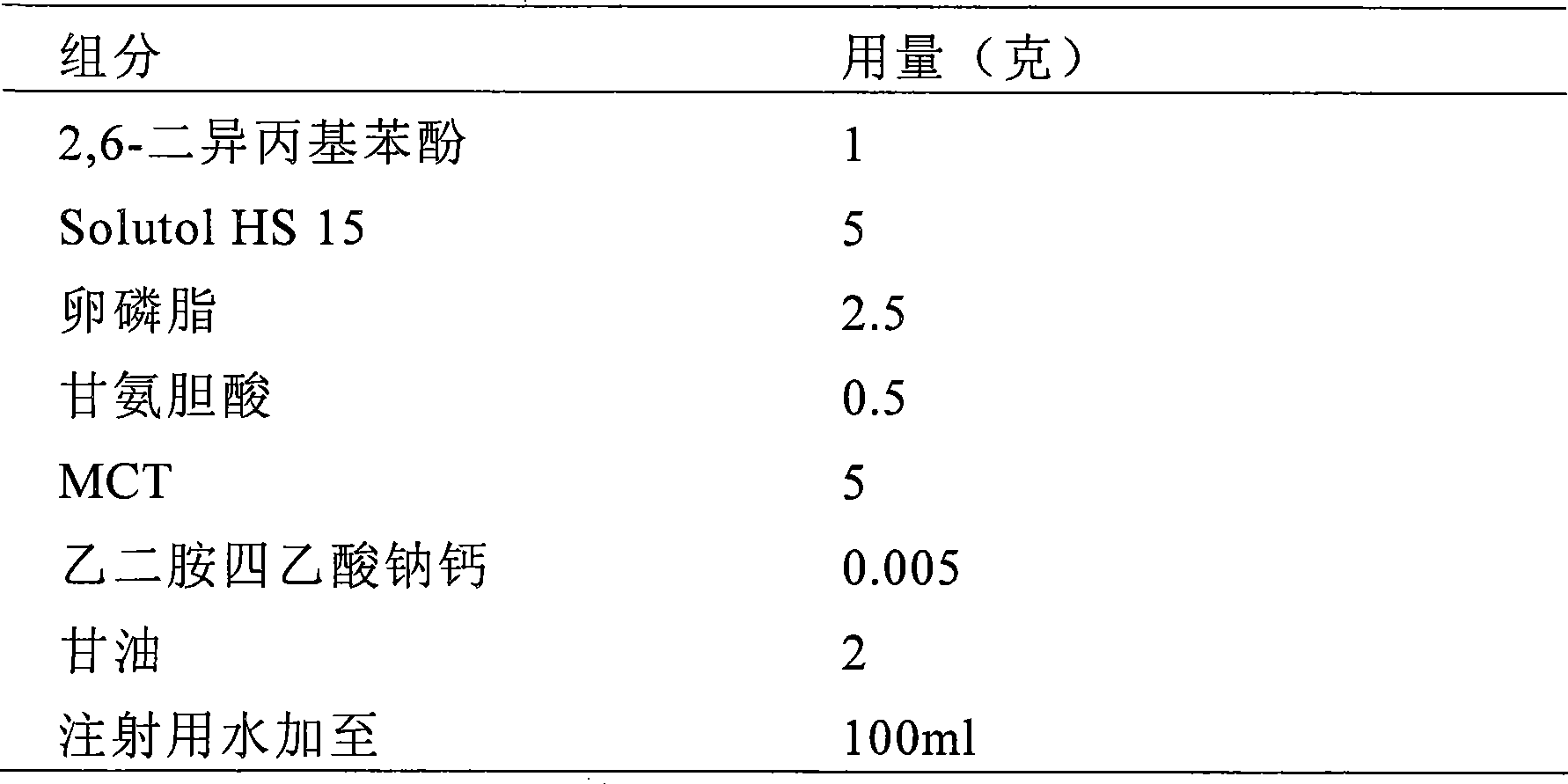

[0046] Composition prescription:

[0047]

[0048] Preparation method: Dissolve lecithin in MCT in a water bath at 65°C, add Solutol HS 15, 2,6-diisopropylphenol, and stir evenly to obtain an oil phase; combine glycocholic acid, sodium calcium ethylenediaminetetraacetate Disperse it with glycerin in about 60ml water, adjust the pH to 7 with sodium hydroxide solution to change glycocholic acid into sodium glycocholate to obtain the water phase; add the water phase to the oil phase under stirring at about 60°C, Continue to stir to obtain microemulsion, filter, add water to 100ml, potting, full nitrogen flow protection, and sterilization.

Embodiment 2

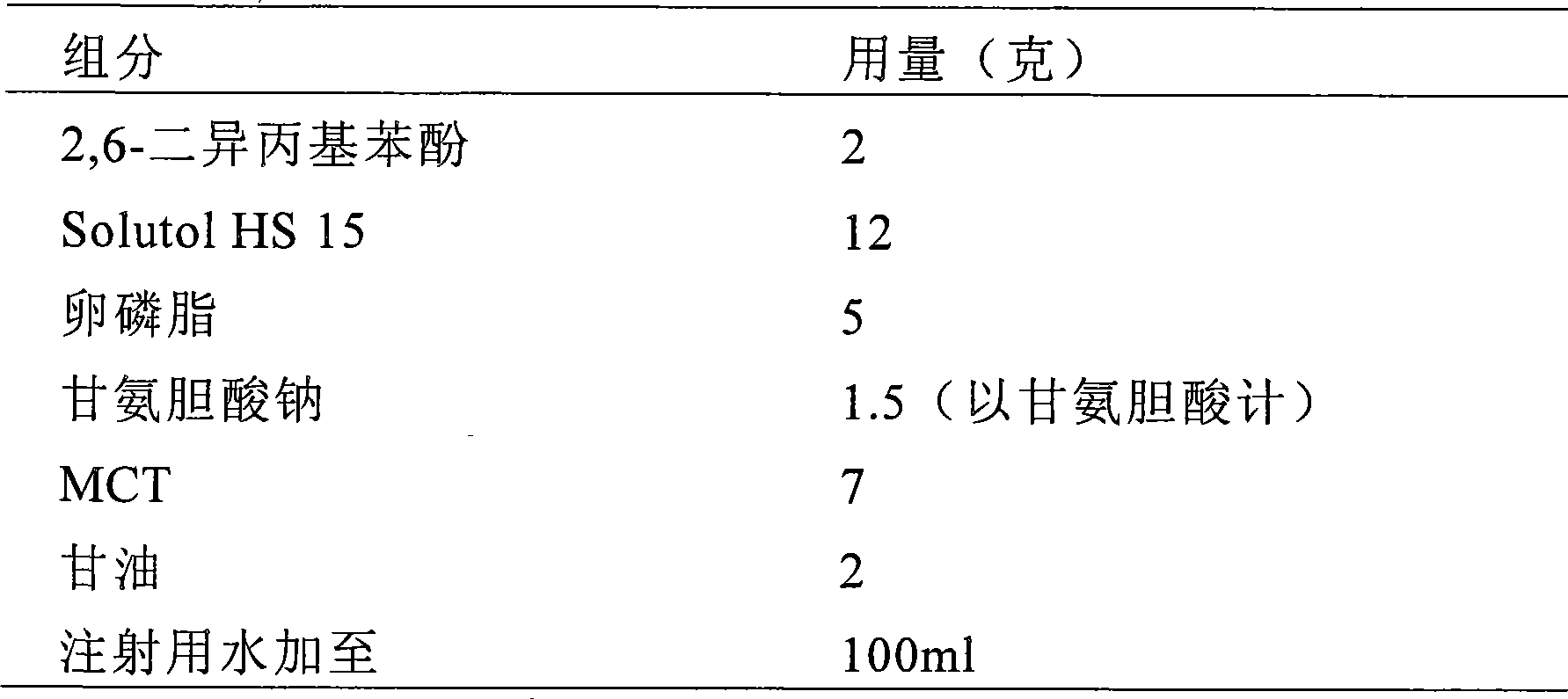

[0050] Composition prescription:

[0051]

[0052] Preparation method: Dissolve lecithin in MCT in a water bath at 60°C, add Solutol HS 15, 2,6-diisopropylphenol, and stir evenly to obtain an oil phase; disperse sodium glycocholate and glycerin in about 60ml water , Adjust the pH to 5 to obtain the water phase; add the water phase to the oil phase under stirring at about 60°C, pass the homogenizer 300Bar homogenization 2 cycles to quickly reach equilibrium, obtain microemulsion, filter, add water to 100ml, It is potted, protected by nitrogen flow throughout, and sterilized.

Embodiment 3

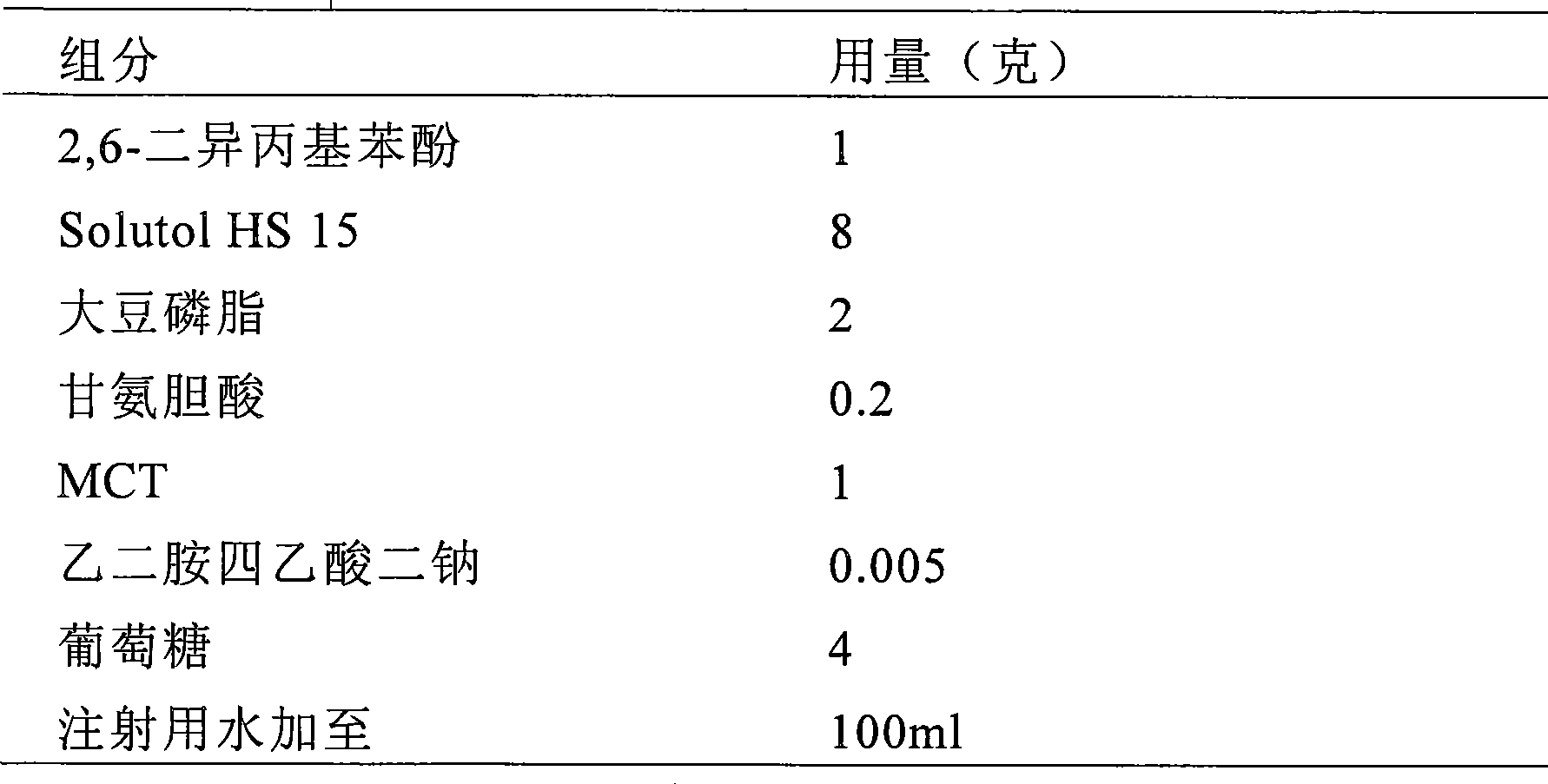

[0054] Composition prescription:

[0055]

[0056] Preparation method: Dissolve soybean phospholipids in soybean oil at 70°C in a water bath, add Solutol HS 15, 2,6-diisopropylphenol, and stir evenly to obtain an oil phase; Disperse sodium and glucose in about 60ml of water, adjust the pH to 6 with sodium hydroxide solution to change glycocholic acid into sodium glycocholate to obtain the water phase; add the water phase to the oil phase with stirring at about 70°C , Continue to stir to obtain microemulsion, filter, add water to 100ml, potting, and sterilizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com