Plant desensitizer and preparation method thereof

An anti-allergic agent, cactus technology, applied in the field of plant anti-allergic agent and its preparation, can solve the problems of high cost, difficult removal, cumbersome operation steps, etc., and achieve the effect of stable quality, simple extraction and separation method, and obvious anti-allergic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1. Production of plant anti-sensitizer

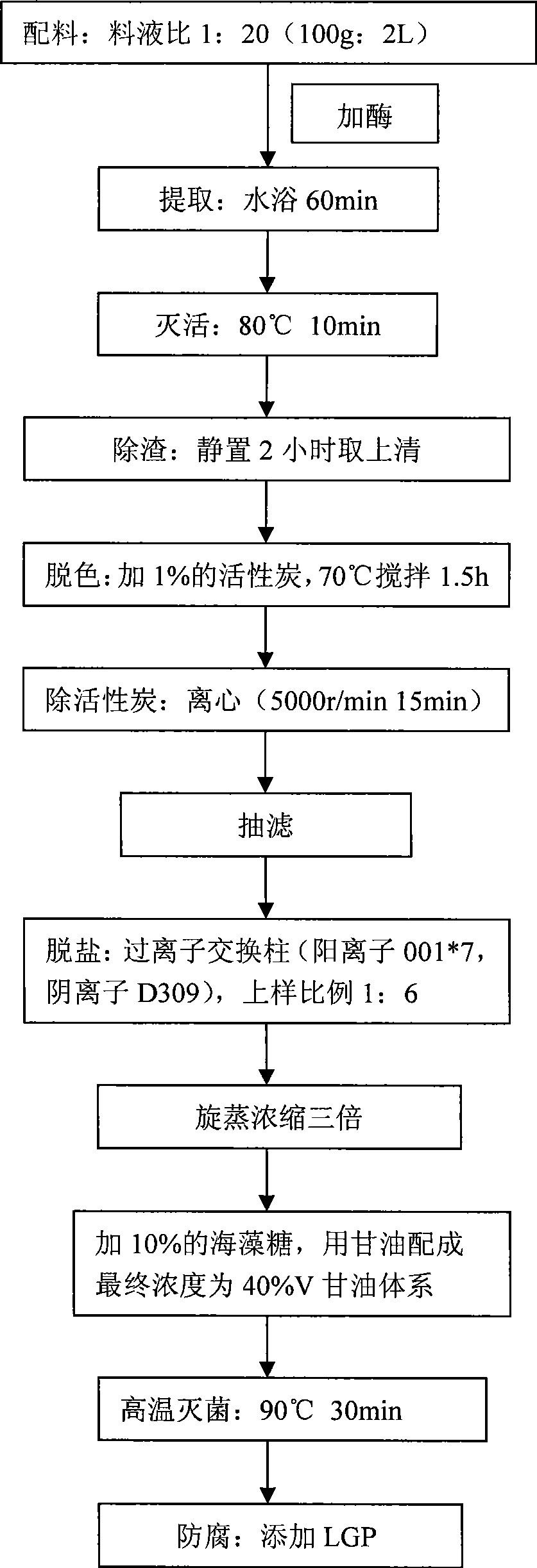

[0026] The production process of plant anti-sensitizers is as follows: figure 1 As shown, the specific process is as follows:

[0027] 1) Mix 100g of cactus powder (purchased from Xinsheng Biotechnology Development Co., Ltd.) and 2L of water at a mass ratio of 1:20, then add 20g of cellulase with an enzyme activity of 1 million U / g, and stir for 1 hour at 50°C , With no precipitation as an indicator, obtain an aqueous solution of cactus powder;

[0028] 2) Heat the above-mentioned aqueous solution of cactus powder at 80°C for 10 minutes to inactivate the enzyme. After the enzyme is inactivated, the solution is allowed to stand for 2 hours, and the supernatant is taken;

[0029] 3) Take 1800ml of the supernatant from the above step 2), adjust the pH to 4.2, and then add 36g of activated carbon to it so that the ratio of activated carbon to the supernatant is 1:50, and stir at 70°C for 1.5 hours;

[0030] 4) The reaction solut...

Embodiment 2

[0035] Example 2. Function test of plant anti-sensitizer

[0036] 1. Moisturizing effect experiment

[0037] Twenty volunteers were selected, half of the volunteers were male and female, the left and right forearms of the volunteers were washed with clean water respectively, and the moisturizing effect experiment was carried out without using any cosmetics.

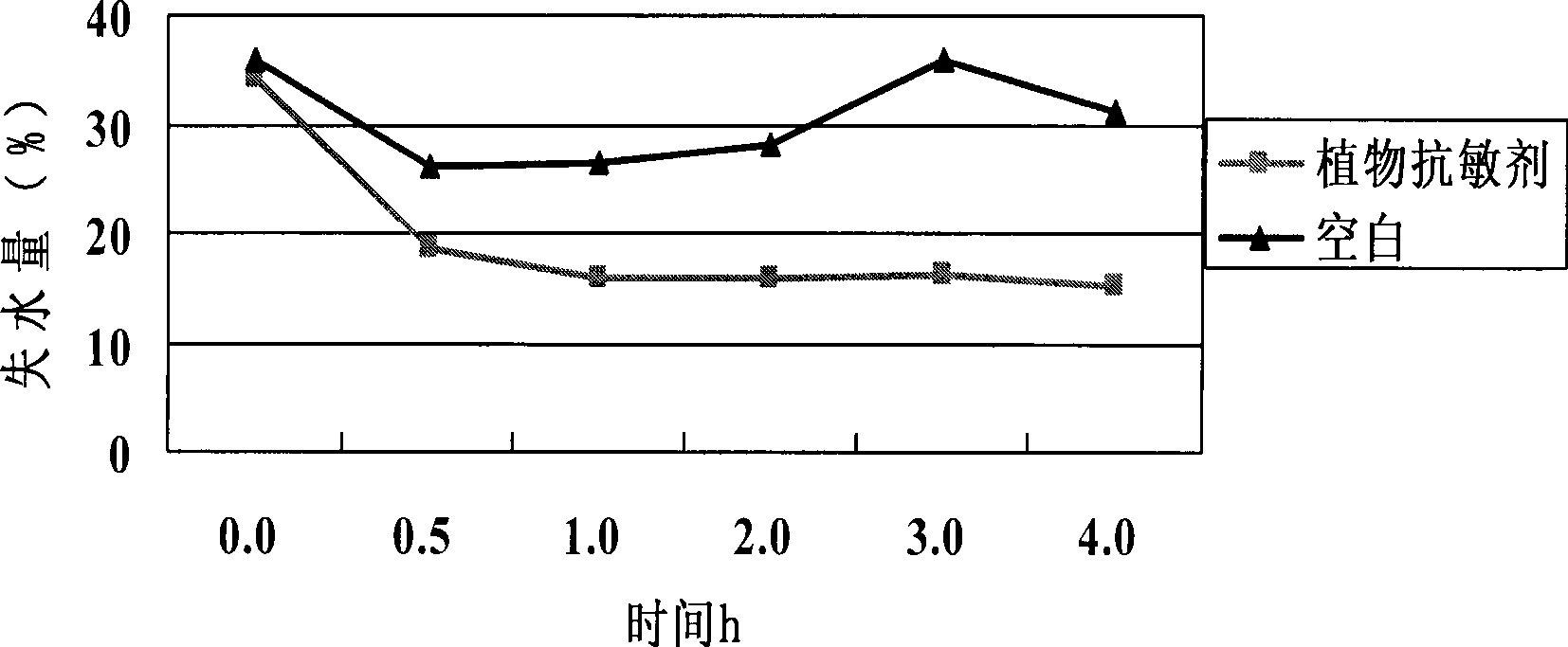

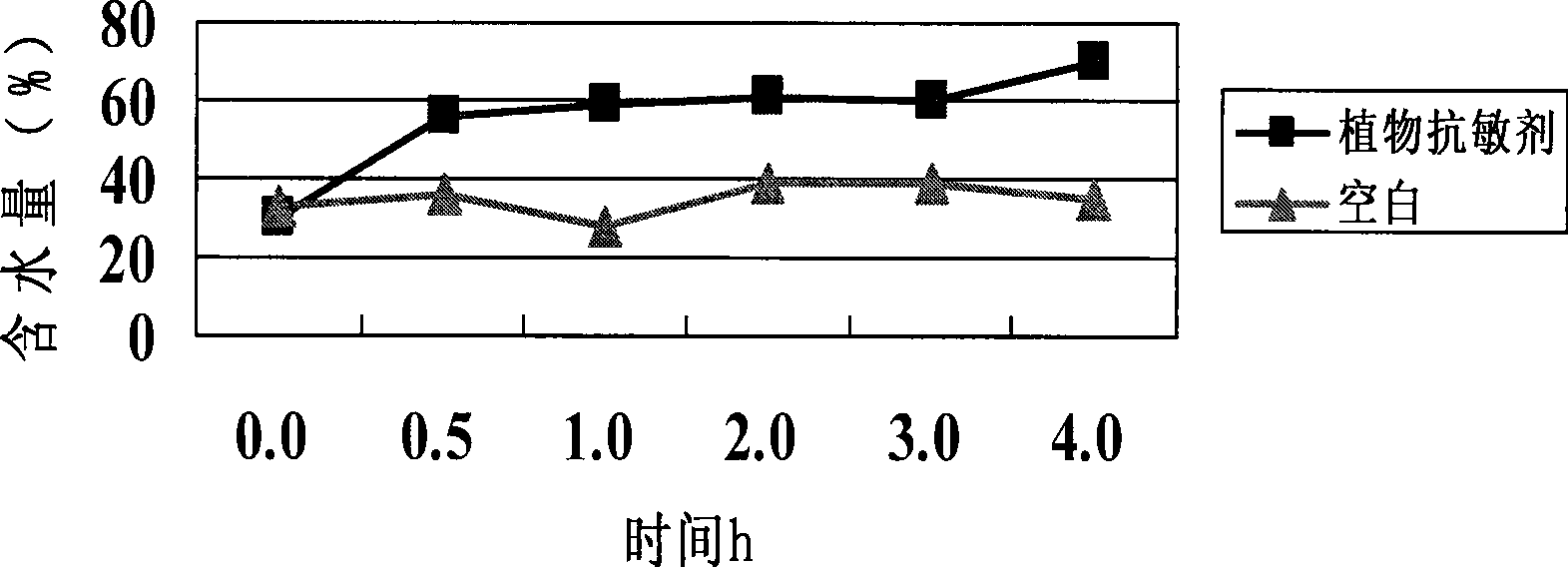

[0038] Test the moisture content and TEWL value of the subject’s left and right forearm skin with a moisture tester, then apply the plant anti-sensitizer prepared in Example 1 on the subject’s left forearm, and use the right forearm as a blank control without applying any cosmetics . Test every half an hour for a total of 4 hours. The experiment is set for three repetitions. The average moisture content and the average moisture loss percentage of the skin surface of the subject change with time as shown in the figure figure 2 with image 3 Shown. The results show that the plant anti-sensitizer prepared in Example 1 has a goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com