Method for preparing optically pure 3-amino butyl alcohol

An aminobutanol and optical technology, applied in the field of chiral drug preparation, can solve the problems of large loss in the splitting process, inability to scale up production, high price, etc., and achieve the effects of improving optical purity, reducing the difficulty of splitting, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

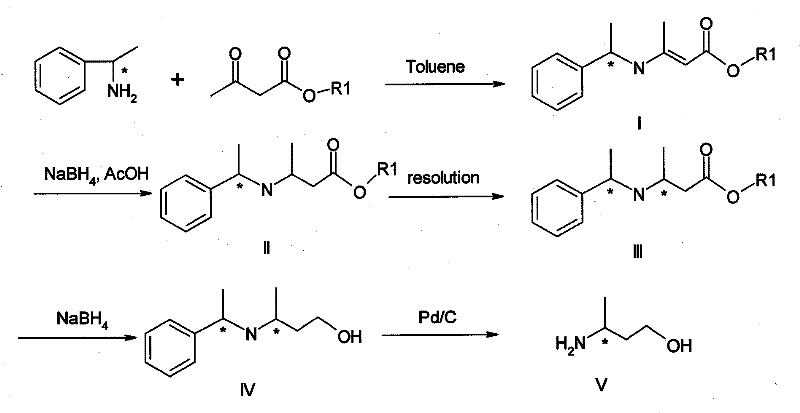

Method used

Image

Examples

Embodiment 1

[0049] Add 62g of methyl acetoacetate, 54g of R-phenethylamine and 150ml of toluene in sequence in a three-necked flask equipped with a thermometer, agitator and water separator, heat, and carry water with toluene. After removing about 8g of water, the reaction is over. After the end, first evaporate toluene and ethyl acetoacetate on a rotary evaporator, and then evaporate a small amount of unreacted R-phenylethylamine under 3-5mmHg to obtain (R, R) and (R, S)-3 -98 g of methyl (1'-methylbenzylamine)-2-butenoate.

Embodiment 2

[0050] Embodiment 2.(1R, 2R) and (1R, 2S)-3-(1'-methylbenzylamine)-2-butenoic acid ethyl ester (I)

[0051] Add 58g of ethyl acetoacetate, 54g of R-phenylethylamine and 150ml of toluene in sequence in a three-necked flask equipped with a thermometer, agitator and water separator, heat, and carry water with toluene, and the reaction ends after removing about 8g of water. After the end, first evaporate toluene and ethyl acetoacetate on a rotary evaporator, and then evaporate a small amount of unreacted R-phenylethylamine at 3-5mmHg to obtain (1R, 2R) and (1R, 2S)-3 -(1'-Methylbenzylamine)-2-butenoic acid ethyl ester 104g

Embodiment 3

[0052] Embodiment 3.(1S, 2S) and (1S, 2R)-3-(1'-methylbenzylamine)-2-butenoic acid methyl ester preparation (I)

[0053] Add 62g of methyl acetoacetate, 54g of S-phenethylamine and 150ml of toluene in sequence in a three-necked flask equipped with a thermometer, agitator and water separator, heat, and carry water with toluene. After removing about 8g of water, the reaction ends. After the end, first evaporate toluene and ethyl acetoacetate on a rotary evaporator, and then evaporate a small amount of unreacted S-phenylethylamine at 3-5mmHg to obtain (1S, 2S) and (1S, 2R)-3 -98 g of methyl (1'-methylbenzylamine)-2-butenoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com