Pressure sensitive viscous composite using rice flour as raw material and use thereof

A viscous composition, the technology of the composition, applied in the directions of starch adhesive, application, adhesive type, etc., can solve the problems of not being popularized and applied, the rebirth of cooked sticky rice cakes, and the short sticking time, etc. Long-term adhesion properties, reproducible tack, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

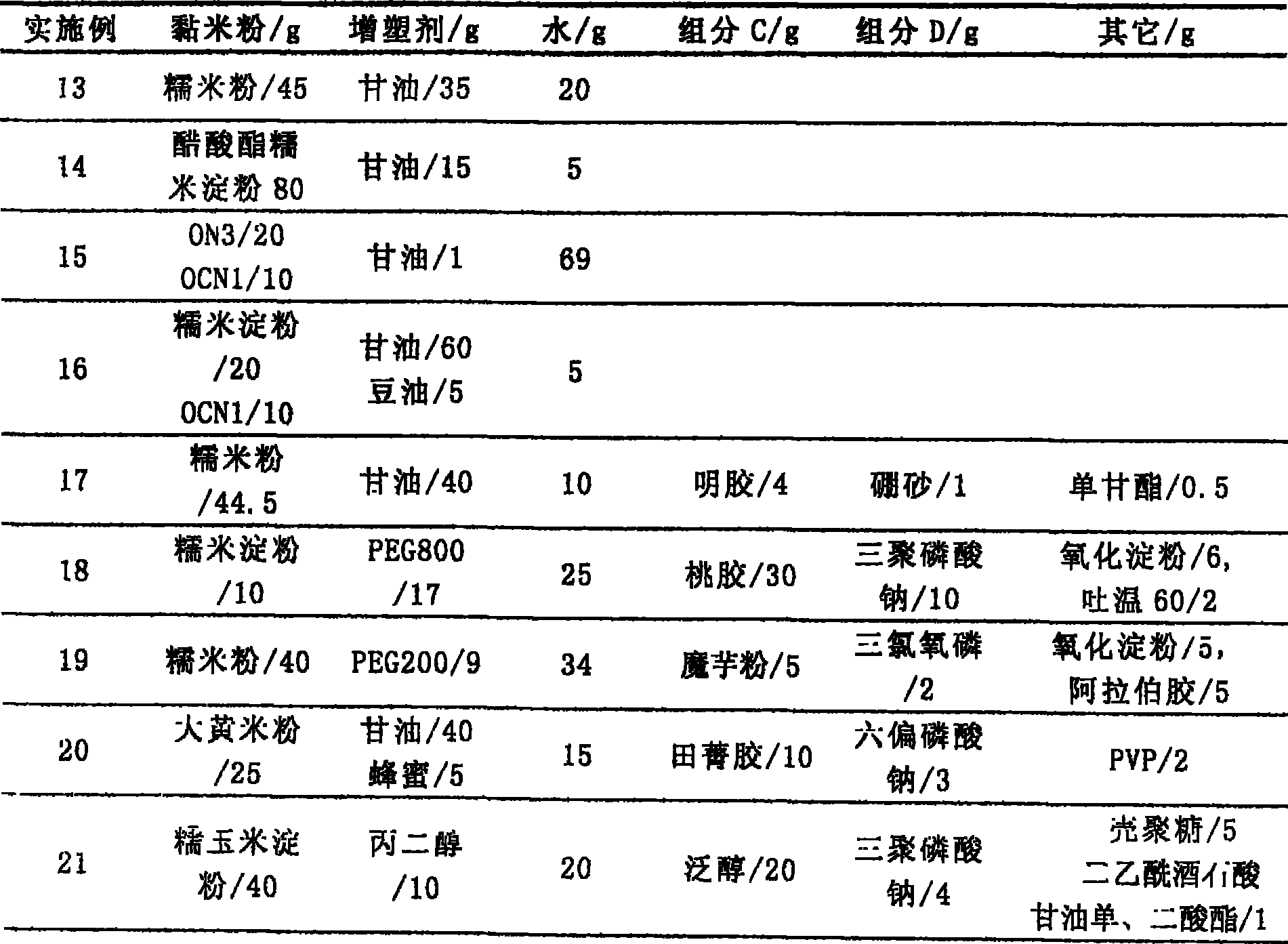

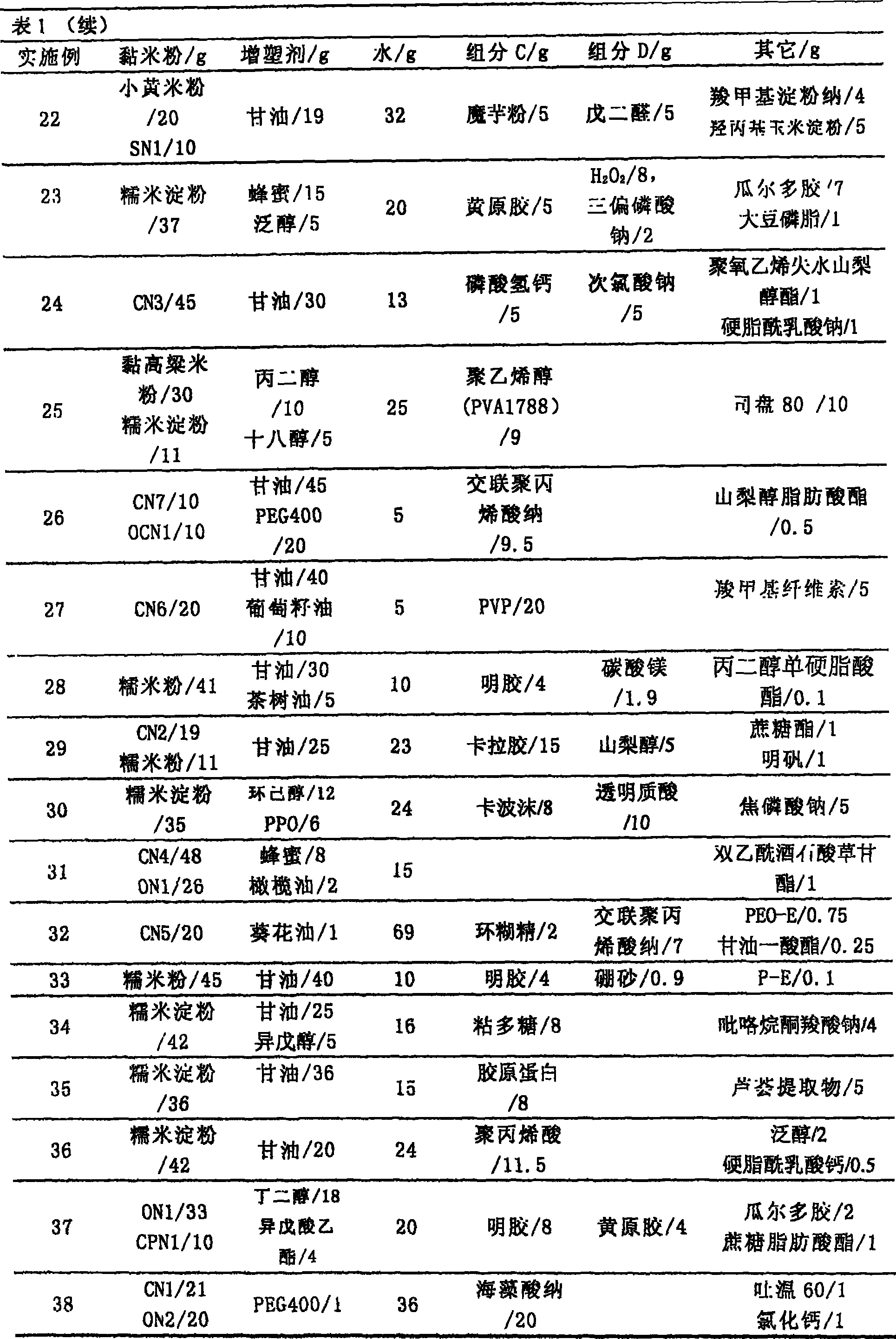

Examples

Embodiment 1

[0036] Add 40g of glutinous rice starch to distilled water containing 2g of sodium tripolyphosphate to make 40% starch milk, stir and adjust the pH value to 10 with 10% sodium hydroxide solution, keep the reaction at 50°C for 24h, neutralize, filter, wash with water and dry , to get cross-linked glutinous rice starch CN1.

[0037] The same method was used to prepare cross-linked waxy corn starch CN2 and sticky sorghum rice cross-linked starch CN3.

Embodiment 2

[0039] Add 40 g of glutinous rice starch into distilled water containing 0.4 g of sodium trimetaphosphate to make 40% starch milk, stir and adjust the pH value to 10 with 10% sodium hydroxide solution, keep the reaction at 50°C for 24 hours, neutralize, filter, wash with water and Dry to obtain cross-linked glutinous rice starch CN4.

Embodiment 3

[0041] Rhubarb rice 100g, first soaked in 0.5% NaOH 200ml at 50°C for 24 hours, then removed the soaking solution, added new lye for wet grinding, and then put it into the sedimentation tank for particle size classification by precipitation method, removed the upper clarified part, washed with water The starch emulsion is centrifuged and dehydrated to separate the starch, dried and crushed to obtain the rhubarb rice starch.

[0042] Weigh 40 g of rhubarb rice starch in distilled water to obtain a starch milk with a mass fraction of 40%, place it in a constant temperature water bath at 30°C, stir, add 0.8 g of anhydrous sodium sulfate, and adjust the pH of the starch milk with a mass fraction of 10% sodium hydroxide. Adjust the value to 10, add 1.2 g of phosphorus oxychloride dropwise, and at the same time add an appropriate amount of 5% sodium hydroxide to keep the pH value of the starch milk constant, react for 2 hours, and neutralize the reaction mixture with hydrochloric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com