Activated sludge solubleness COD measuring method

A technology of chemical oxygen demand and measurement method, which is applied in the field of determination of activated sludge dissolved chemical oxygen demand, can solve the problem of accurate evaluation of cell lysis technology, difficult membrane filtration, and accurate determination of dissolved chemical oxygen demand, etc. problem, to achieve the effect of reliable principle, simple preparation and large amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

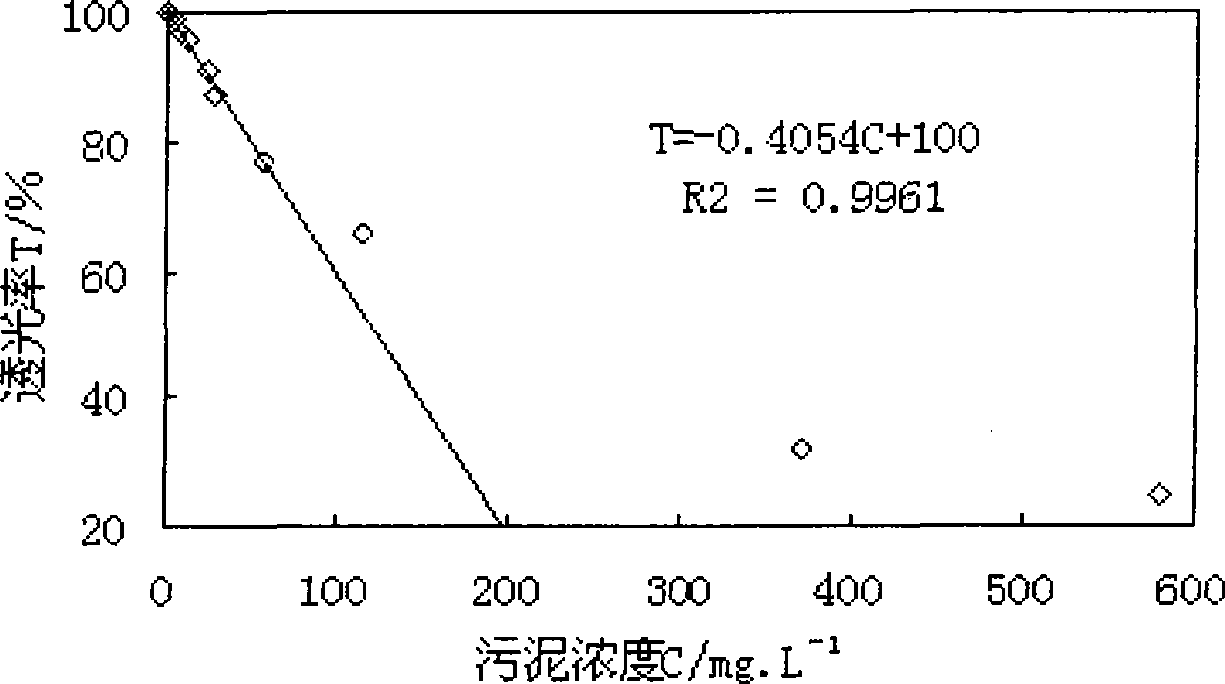

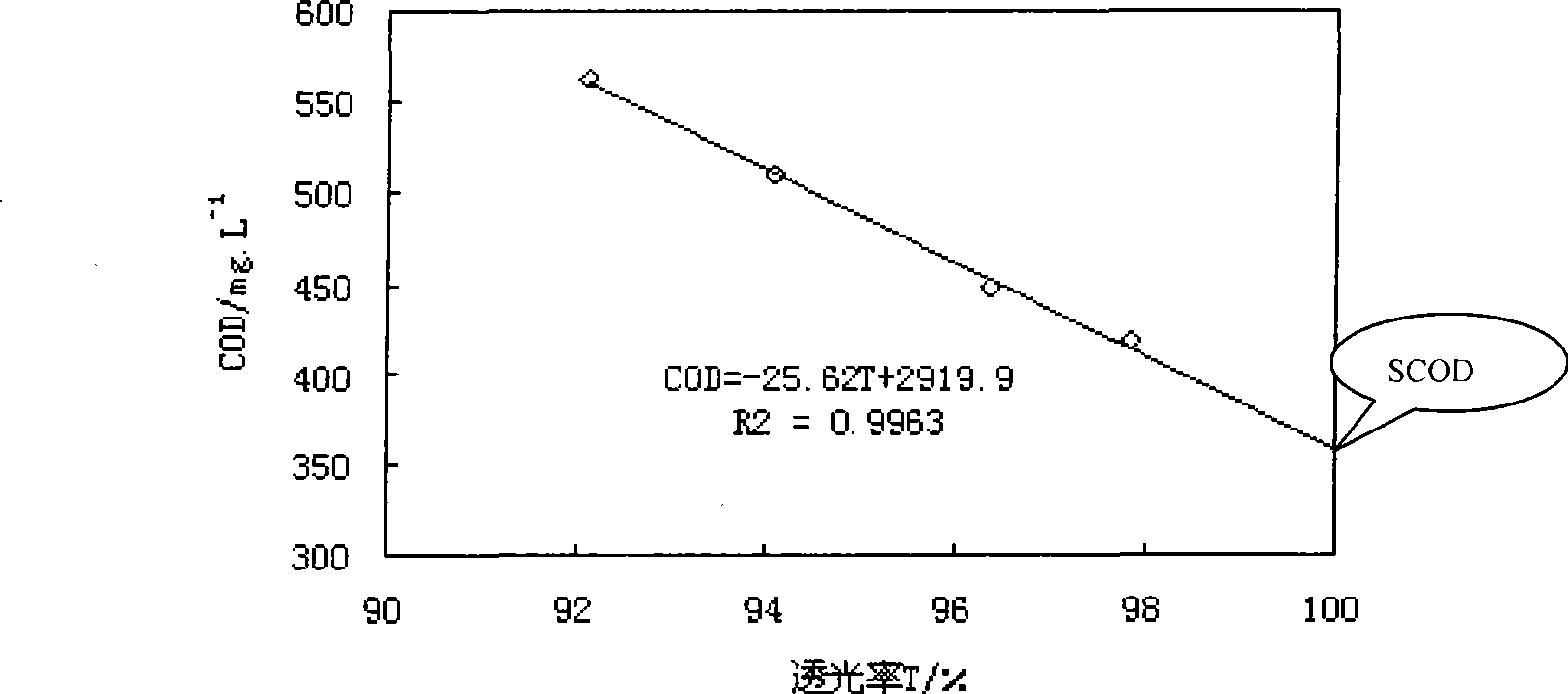

[0034] Take 1L of excess sludge with a water content of 98.5% from a sewage plant, adjust the pH to 10.0 with sodium hydroxide (NaOH), and treat it with a tank-type ultrasonic wave with a frequency of 25kHz and a power of 50W for 30min. Then take 4 parts of 50ml lysed sludge and centrifuge respectively at 5000g for 5min, 8min, 10min and 15min at a centrifugal acceleration, take out the upper suspension and measure the light transmittance at a detection wavelength of 630nm, then use the potassium dichromate titration method Analyze the chemical oxygen demand (COD) data of the suspension, and plot the light transmittance and COD in the Excel software (such as figure 2 ), according to the data, use the Excel linear regression function to perform linear regression to obtain a linear equation:

[0035] COD=2919.9-25.62T (5)

[0036] Then use equation (5) to calculate the chemical oxygen demand when the light transmittance is 100%, which is 358.4mg / L. This data is the dissolved c...

Embodiment 2

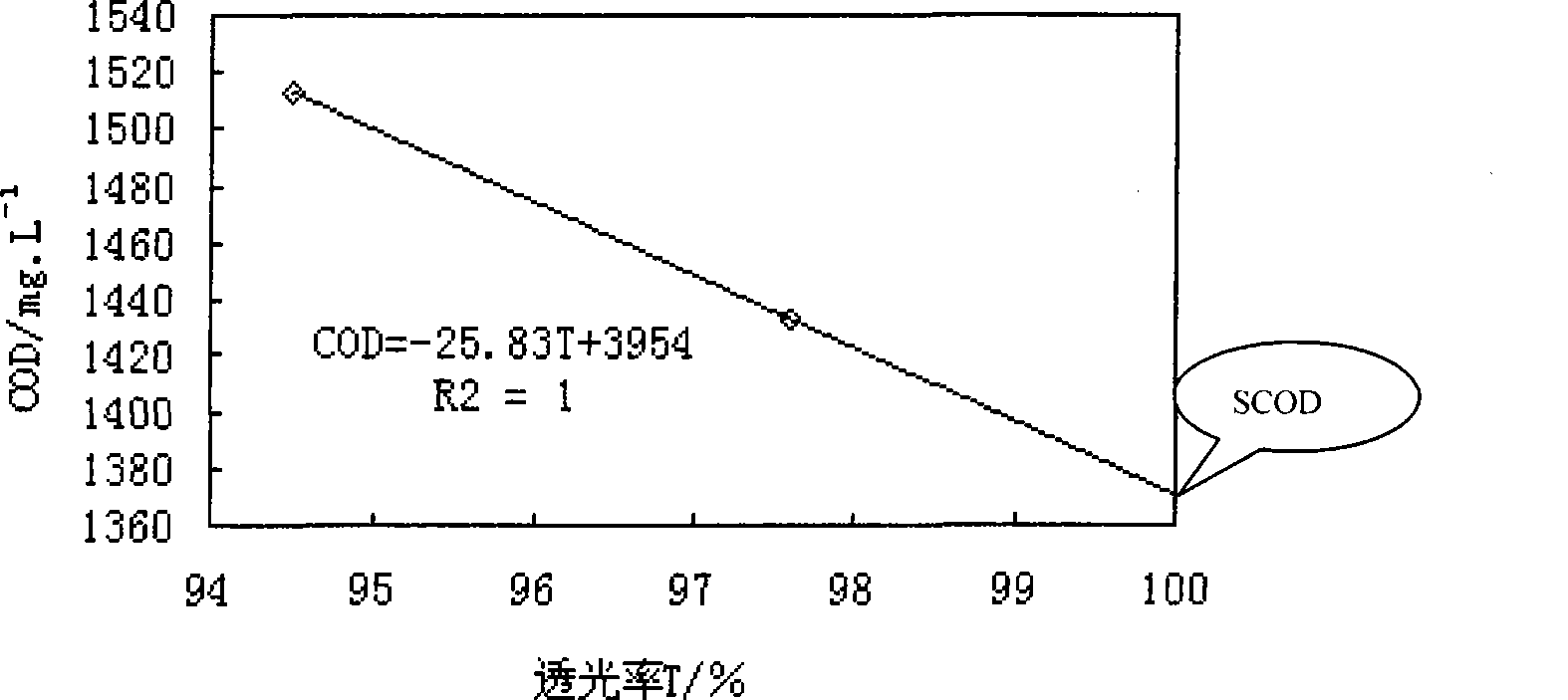

[0038] With embodiment 1. The difference is that the pH of the sludge is 11.0, the ultrasonic treatment is 60 minutes, and two parts of 50ml volume of lysed sludge are centrifuged at the centrifugal accelerations of 5000g and 8000g for 10min respectively. Use Excel software to plot the data (such as figure 2 shown), and utilize Excel software to carry out linear regression to obtain the linear equation of light transmittance and chemical oxygen demand:

[0039] COD=3954-25.83T (6)

[0040] According to equation (6), the dissolved chemical oxygen demand when the light transmittance is 100% is 1371mg / L, while the corresponding value of 0.45um membrane filtration method is 1425mg / L, and the relative error is 3.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com