Nano-silicon air-sensitive material and gas sensor

A technology of gas-sensitive materials and gas-sensitive elements, which is applied in the field of new material technology and nanomaterials, can solve the problems that it is difficult to achieve ultra-micro-quantity rapid detection, and the sensitivity and selectivity cannot meet the requirements of ultra-micro-quantity rapid detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

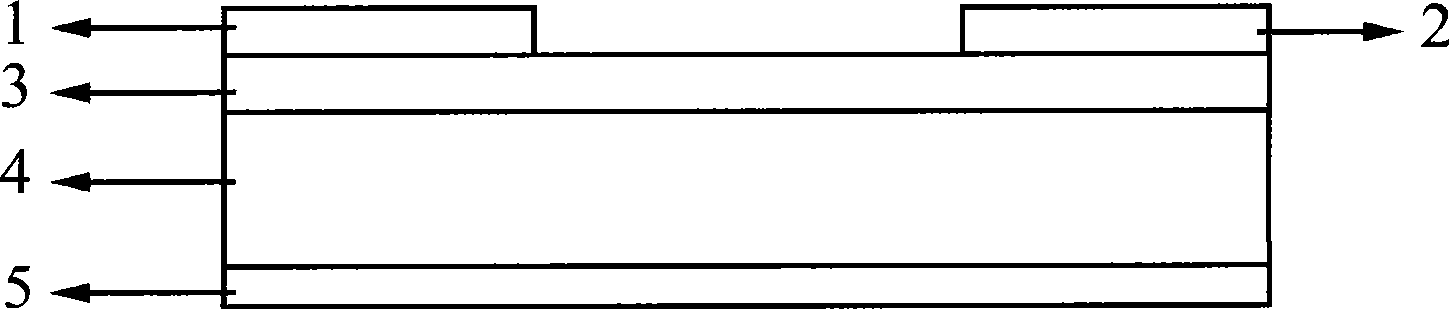

Image

Examples

specific Embodiment approach 2

[0028] On the surface of the cleaned silicon chip, deposit a 30nm thick Ag film by electroless plating, then immerse the sample that is deposited with the silver film in a closed container kettle containing hydrofluoric acid and hydrogen peroxide mixed solution (the concentration of hydrofluoric acid and hydrogen peroxide The concentrations are respectively 4.0 mol / L and 0.2 mol / L) and treated for 30 minutes to obtain a large-area nano-silicon material. Metal ohmic electrodes at a certain distance are deposited on the surface of the nano-silicon material, and the outer leads can be drawn out to become a simple gas sensor.

specific Embodiment approach 3

[0029] The cleaned silicon wafer is directly immersed in a closed container kettle containing a mixed solution of hydrofluoric acid and silver nitrate (concentrations of hydrofluoric acid and silver nitrate are respectively 4.0mol / L and 0.02mol / L) and treated for 30 minutes to obtain Large-area nano-silicon material. Metal ohmic electrodes at a certain distance are deposited on the surface of the nano-silicon material, and the outer leads can be drawn out to become a simple gas sensor.

specific Embodiment approach 4

[0030] On the surface of the cleaned silicon chip, deposit a 30nm thick Ag film by electroless plating, then immerse the sample that is deposited with the silver film in a closed container kettle containing hydrofluoric acid and hydrogen peroxide mixed solution (the concentration of hydrofluoric acid and hydrogen peroxide The concentrations are respectively 4.0mol / L and 0.2mol / L) and treated for 40 minutes to obtain a large-area nano-silicon material. Metal ohmic electrodes are deposited on the surface and back of the nano-silicon material, and a simple gas sensor can be formed after the outer lead is drawn out.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap