Nano composite electrode preparation for dye sensitization solar cell

A technology for solar cells and dye sensitization, which is applied in the field of preparation of nanocomposite electrodes, can solve the problems of increasing the recombination of photogenerated electrons and holes, increasing the coincidence of photogenerated electrons and holes, and lengthening the electron path, so as to increase the excitation of dyes. The probability of increasing the photoelectric efficiency, the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

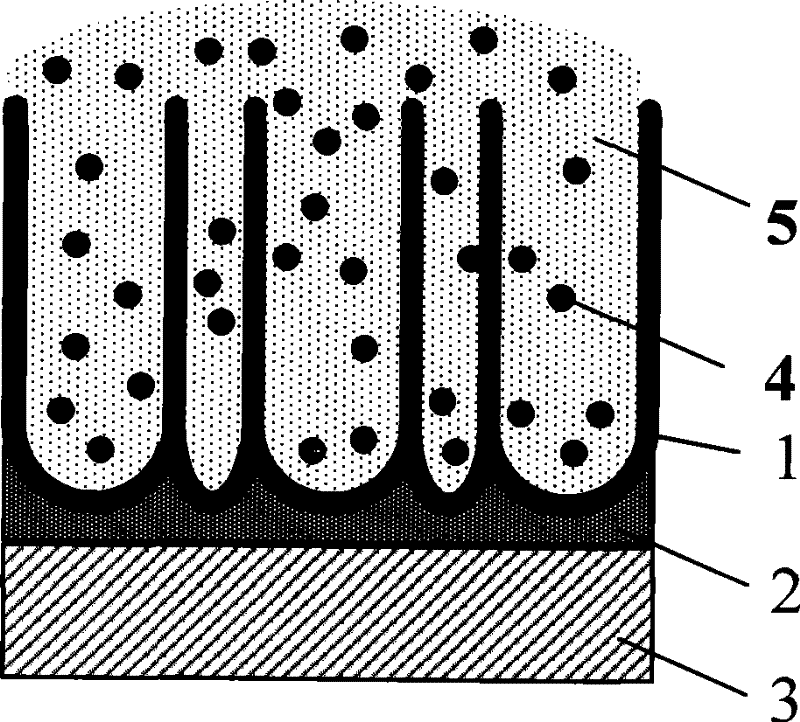

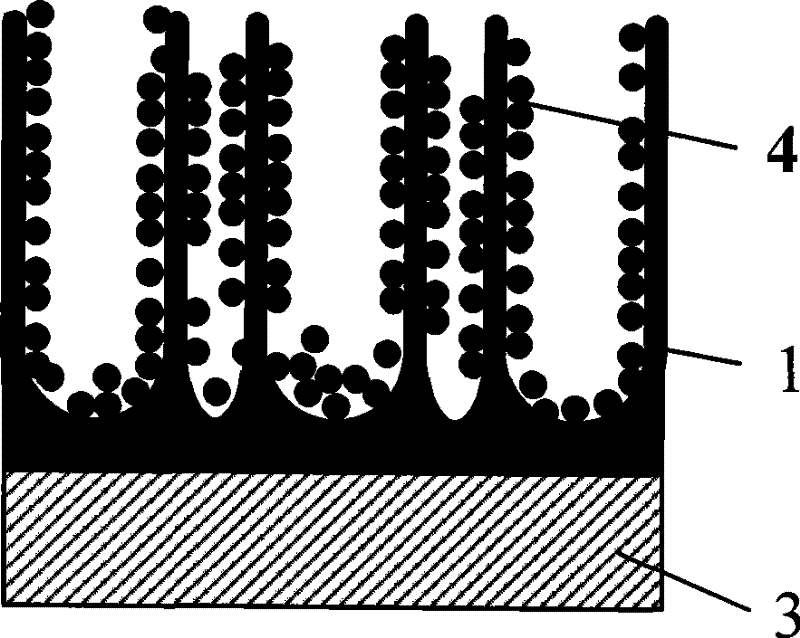

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] The transparent conductive substrate adopts the FTO (F-doped tin oxide) conductive glass of Japan Nippon Sheet Glass Company. The conductive glass is cleaned in an ultrasonic water bath and then dried and placed in a magnetron sputtering chamber. The sputtering was carried out in an Ar gas atmosphere, the sputtering power was 1000W, the substrate temperature was room temperature, and the sputtering deposition rate was 10nm / min. Finally, a dense Ti metal film with a thickness of 2um was deposited on the surface of the conductive glass.

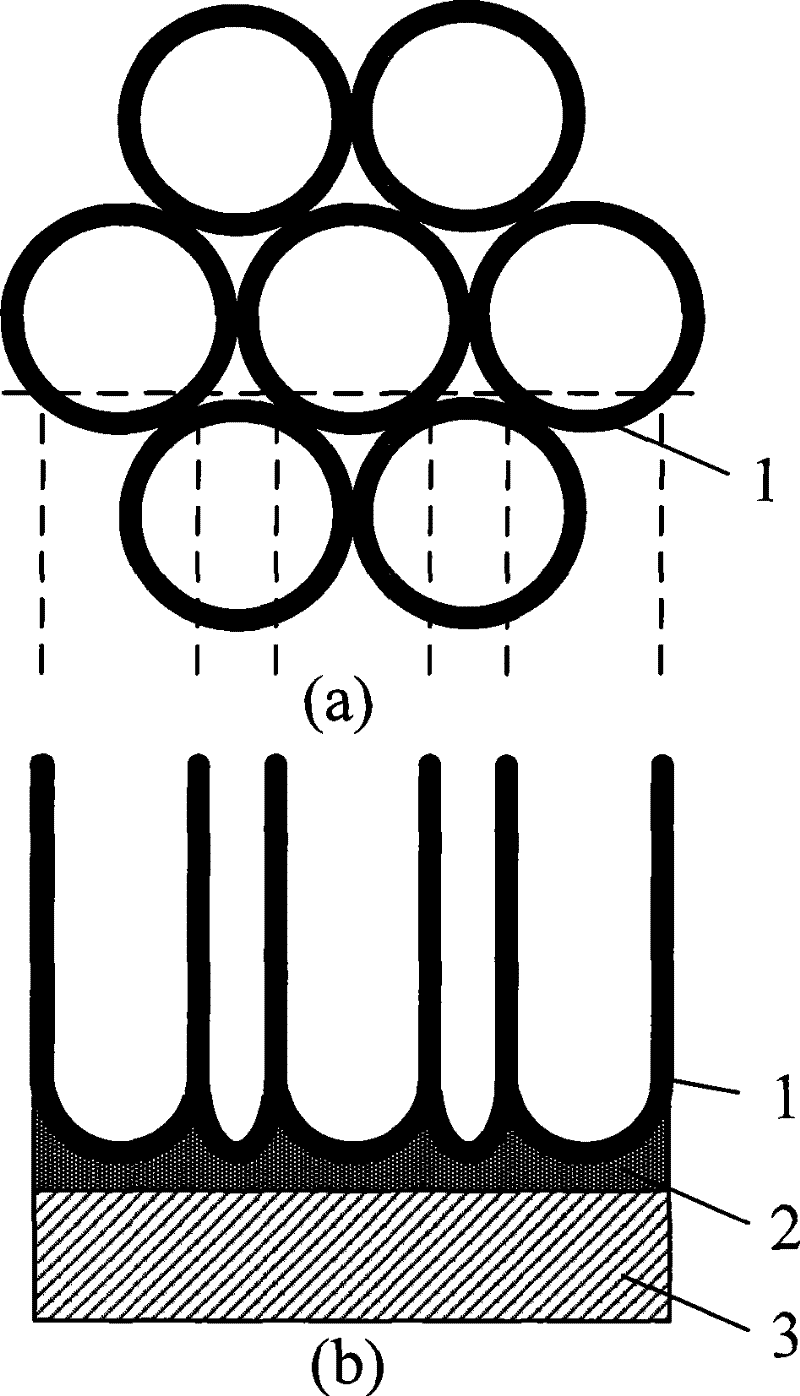

[0021] Then the samples were anodized to prepare TiO 2 array of nanotubes. The sample is connected to the positive electrode of the constant voltage source, and the Pt sheet is connected to the negative electrode, and put into the corrosion solution for anodic oxidation operation. The etching solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com