Instant film preparation containing phenylephrine hydrochloride

A technology of phenylephrine hydrochloride and film preparation, which is applied in the direction of medical preparations containing active ingredients, organic active ingredients, chemical instruments and methods, etc., which can solve the problems of non-existence and achieve high yield and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

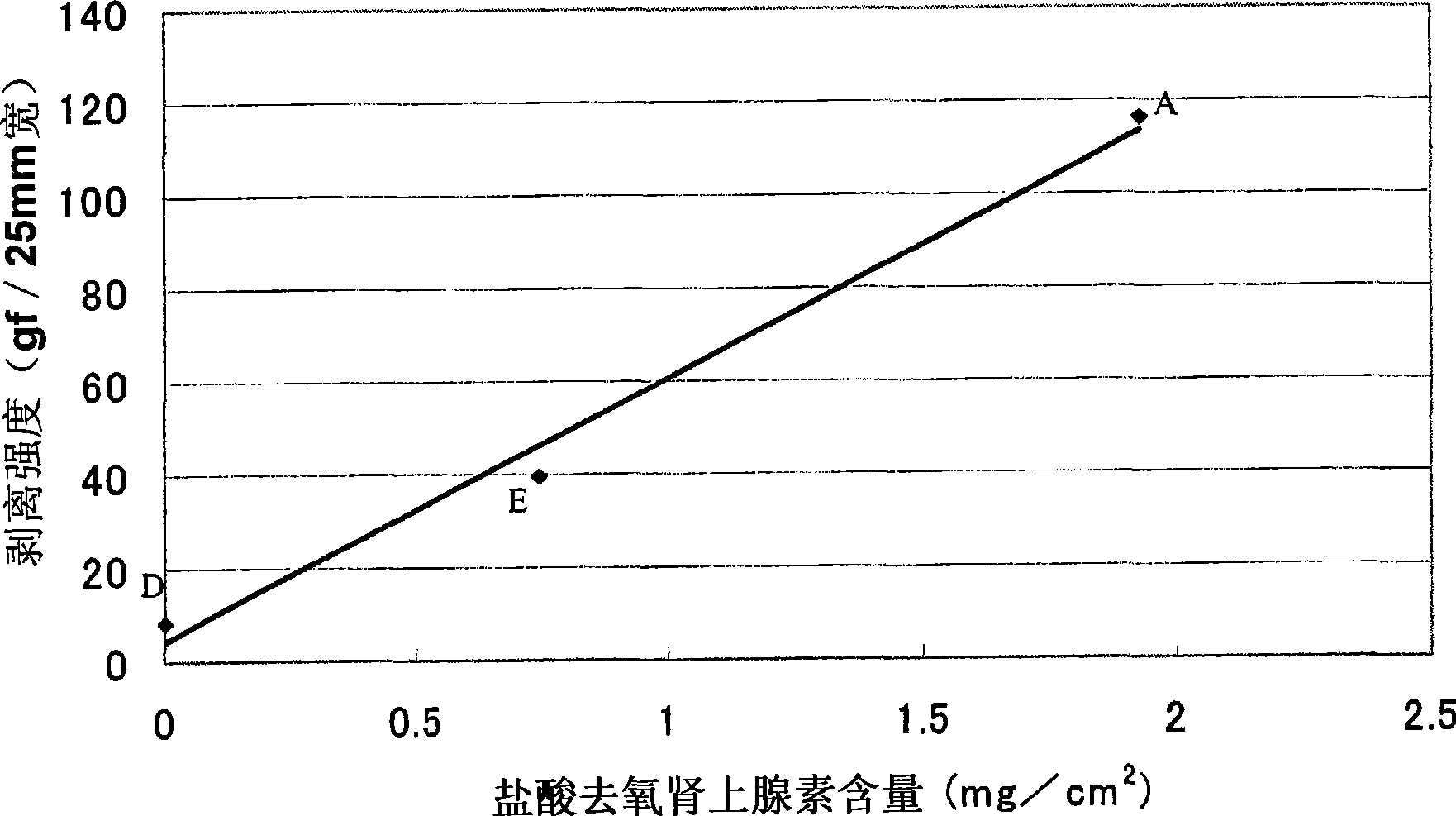

Examples

Embodiment 1

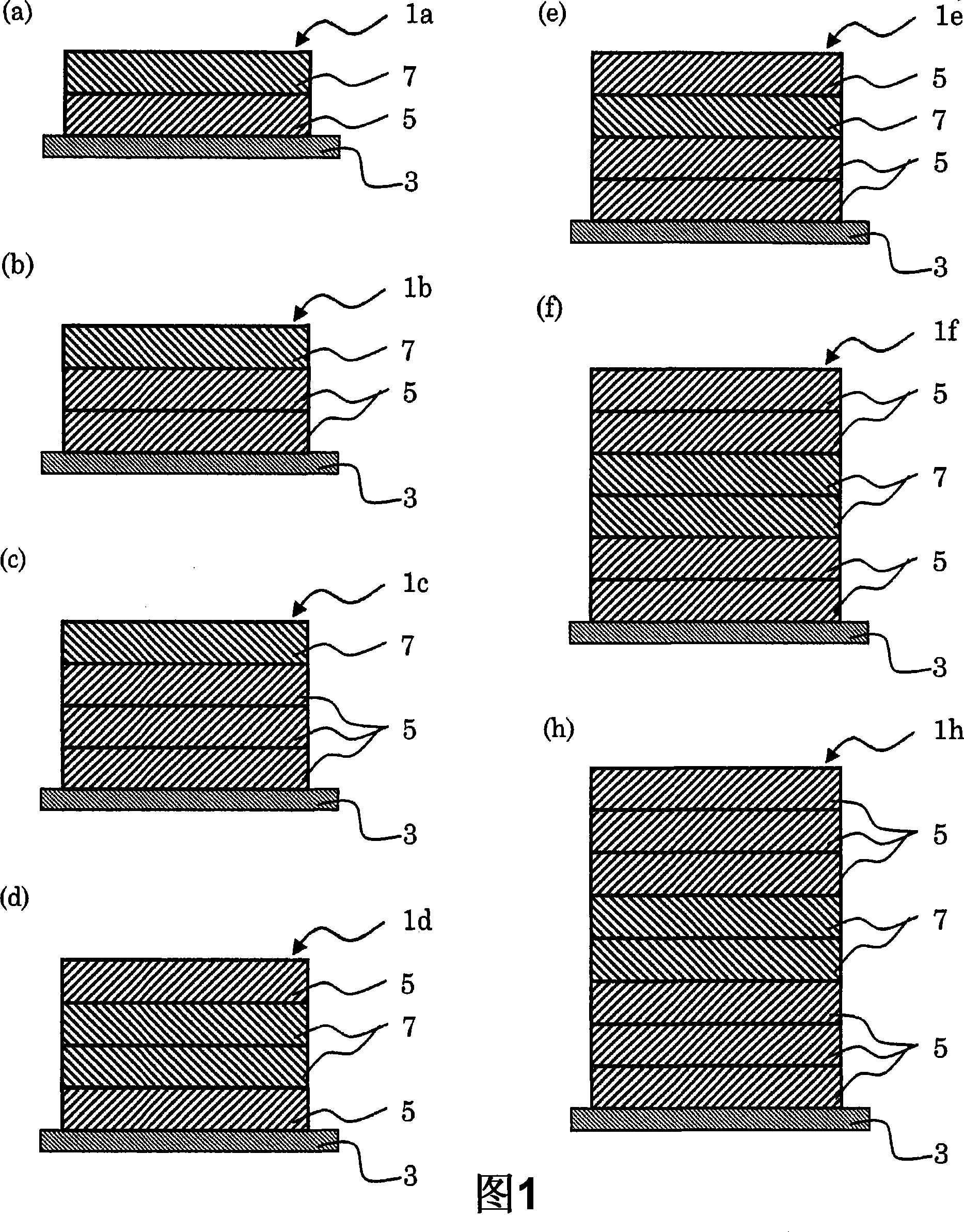

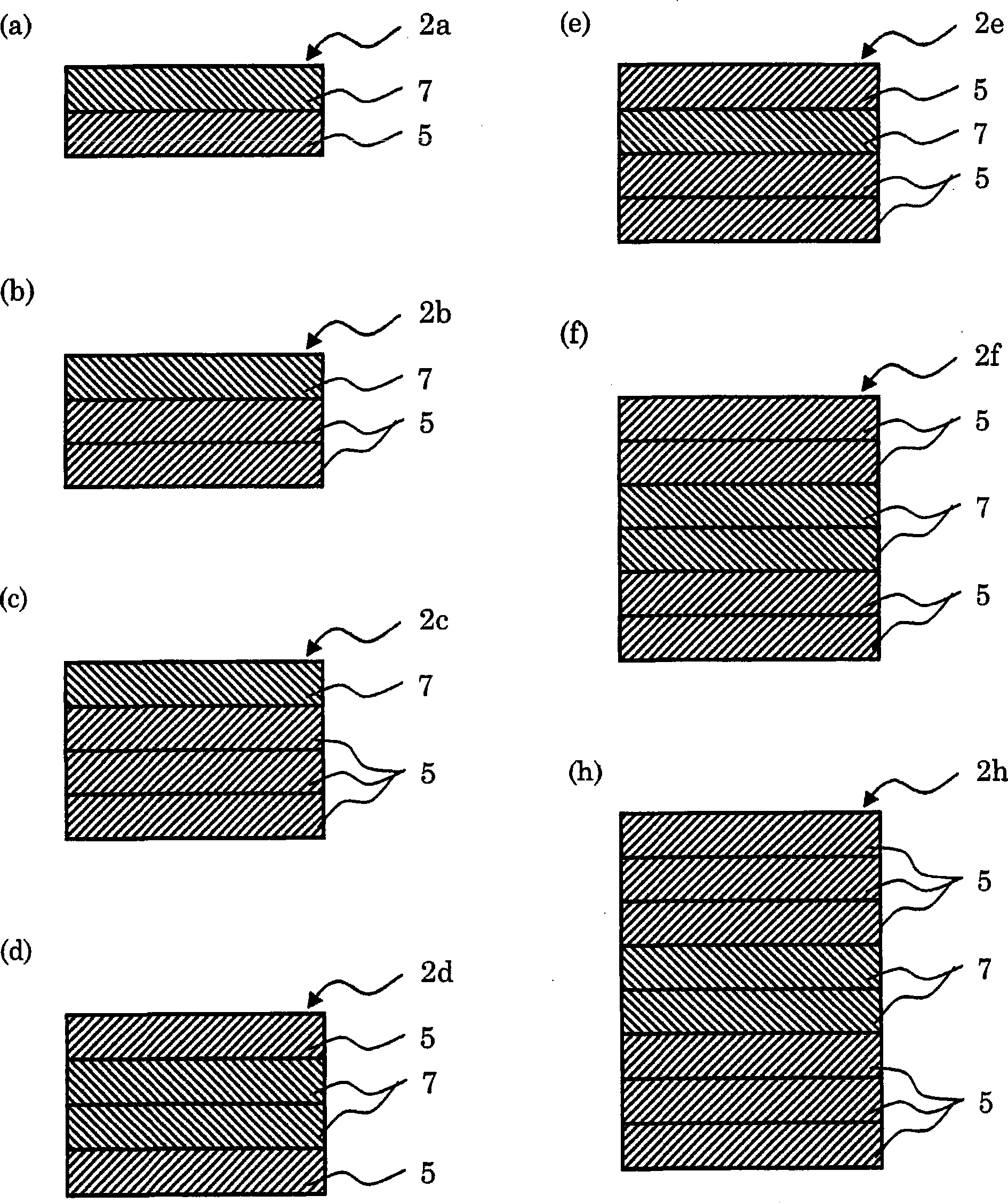

[0483] Manufacture of 6-layer film preparation

[0484] Dissolve 157.5g phenylephrine hydrochloride, 60g d-chlorpheniramine maleate, 6g belladonna total alkaloids, 30g erythritol, 30g sodium saccharin and 6g sodium bisulfite in 540g water, add 360g absolute ethanol. 318 g of HPC (d) was added to this solution to obtain a drug-containing layer preparation.

[0485] Dissolve 25g of powdered reduced maltose syrup in 168g of water. Add 15g of titanium oxide and 0.1g of edible blue No. 1 aluminum precipitation colorant dispersed in 112g of absolute ethanol to this liquid, add 60g of HPMC (b) again, obtain the first shielding layer preparation liquid.

[0486] Dissolve 6g of 1-menthol in 150g of absolute ethanol, add 150g of water in this liquid. 97 g of HPMC (a) was added to this solution to obtain a second masking layer preparation solution.

[0487] Next, fix the polyethylene terephthalate film (PET film) with silicone release treatment on the back side to the unwinding shaft...

Embodiment 2

[0496] Production of 4-layer film preparation

[0497] Dissolve 157.5g phenylephrine hydrochloride, 60g d-chlorpheniramine maleate, 6g belladonna total alkaloids, 30g erythritol, 30g sodium saccharin and 6g sodium bisulfite in 540g water, add 360g absolute ethanol and 1.8g 1-menthol. 316.2 g of HPC (d) was added to this solution to obtain a drug-containing layer preparation.

[0498] 20 g of pullulan was added to 40 g of water to obtain a masking layer preparation solution.

[0499] Next, the PET film on the back surface of which the silicone release treatment was performed was fixed on the unwinding shaft of the coater, the masking layer preparation solution was supplied to the weir portion, and the masking layer preparation solution was coated on the non-release-treated surface of the PET film. Dry with hot air to form an edible masking layer with a thickness of 20 μm.

[0500] Then, on the unwinding shaft, fix again the PET film that is formed with the masking layer. 2 ...

Embodiment 3

[0505] Production of 4-layer film preparation

[0506] Dissolve 157.5g phenylephrine hydrochloride, 60g d-chlorpheniramine maleate, 6g belladonna total alkaloids, 30g erythritol, 30g sodium saccharin and 6g sodium bisulfite in 540g water, add 360g absolute ethanol and 1.8g 1-menthol. 316.2 g of HPC (d) was added to this solution to obtain a drug-containing layer preparation.

[0507] Add 20 g of PVP (K-90) to 80 g of water to obtain a masking layer preparation solution.

[0508] Next, the PET film on the back surface of which the silicone release treatment was performed was fixed on the unwinding shaft of the coater, the masking layer preparation solution was supplied to the weir portion, and the masking layer preparation solution was coated on the non-release-treated surface of the PET film. Dry with hot air to form an edible masking layer with a thickness of 25 μm.

[0509] Then, on the unwinding shaft, fix again the PET film that is formed with the masking layer. 2 ) to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com