Rigid PVC co-extrusion wood-like outdoor furniture section steel and preparation method thereof

A technology of imitating wood grain and PVC resin, applied in the polymer field, can solve the problems of easy water absorption, waste of manpower, material resources, increase manufacturing cost, etc., and achieve the effect of avoiding environmental pollution, reducing process steps and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0032] Embodiment 1: Base mix

[0033] (1) Take 100 parts of PVC resin (SG-5 or S-1000) and add it to a high-speed mixer for high-speed stirring (depending on the friction between the material and the stirring paddle and the wall of the pot to heat up, the stirring paddle is divided into upper and lower layers, high-speed Stirring is the main motor speed is 1470r / min), when the temperature of the material rises to 80°C, add calcium-zinc composite stabilizer, stir at a high speed to 100°C, add other additives, and then stir for 5 minutes before feeding, cold mixing, until 50°C, discharging and sealing storage.

[0034] (2) Take 50 parts of regenerated materials of hard PVC waste products and 50 parts of PVC resin (SG-5 or S-1000) and add them to a high-speed mixer for high-speed stirring (depending on the friction between the material and the stirring paddle and the pot wall) Heat up, the stirring paddles are divided into upper and lower layers, high-speed stirring (the main m...

Embodiment approach 2

[0035] Embodiment 2: Blending of Fabrics

[0036] Take 100 parts of PVC resin (SG-6 or S-800) and add it to a high-speed mixer for high-speed stirring (depending on the friction between the material and the stirring paddle and the pot wall to heat up, the stirring paddle is divided into upper and lower layers, and the high-speed stirring is the main motor. The rotation speed is 1470r / min), when the temperature of the material rises to 80°C, add calcium-zinc composite stabilizer and epoxy soybean oil and stir at a high speed until the temperature is 100°C, add color masterbatch and other additives, and then stir for 5 minutes before feeding and cold mixing to Store at 50°C in an airtight container.

Embodiment approach 3

[0037] Embodiment 3: Co-extrusion molding of rigid PVC gazebo

[0038] Host extrusion process:

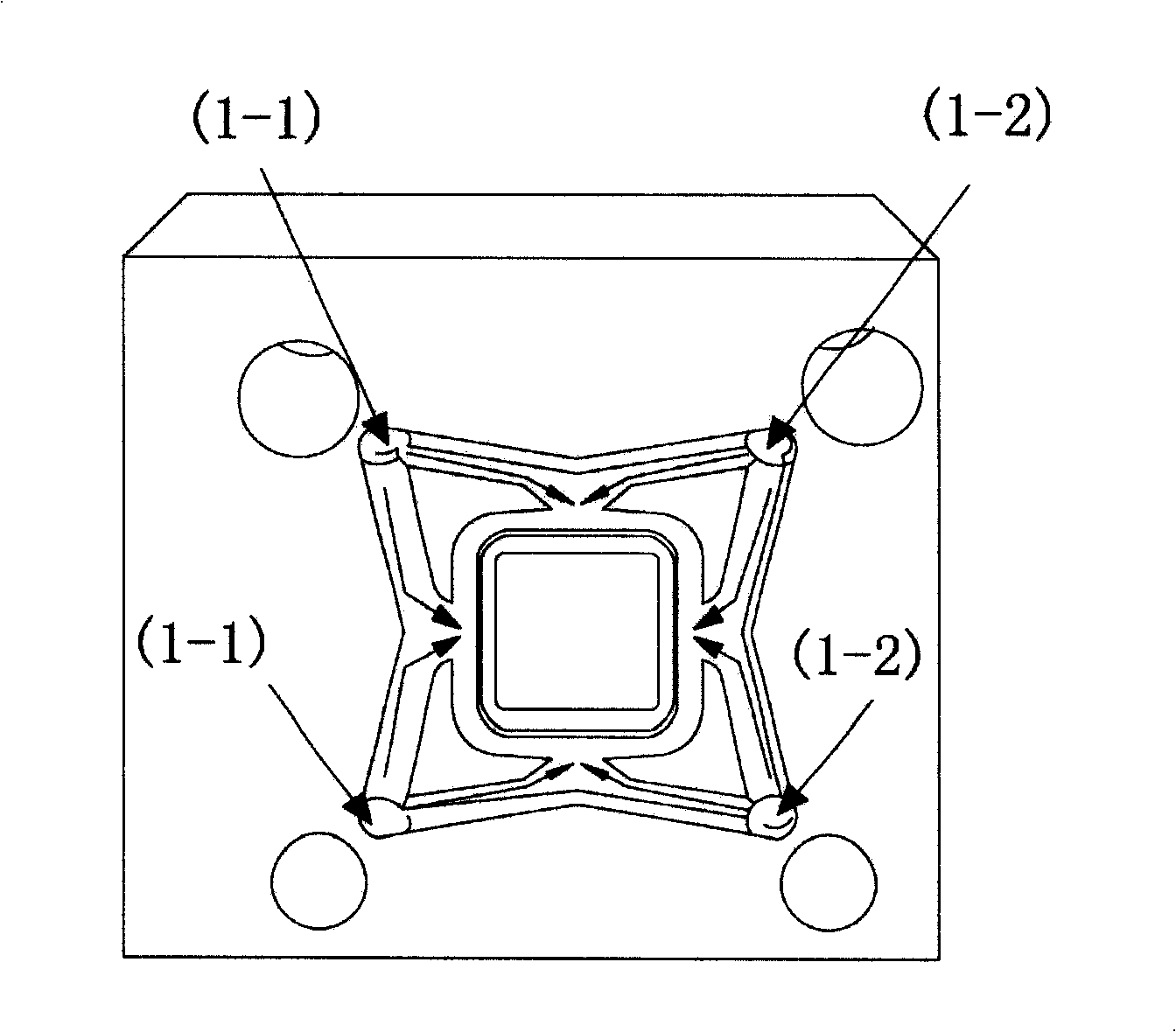

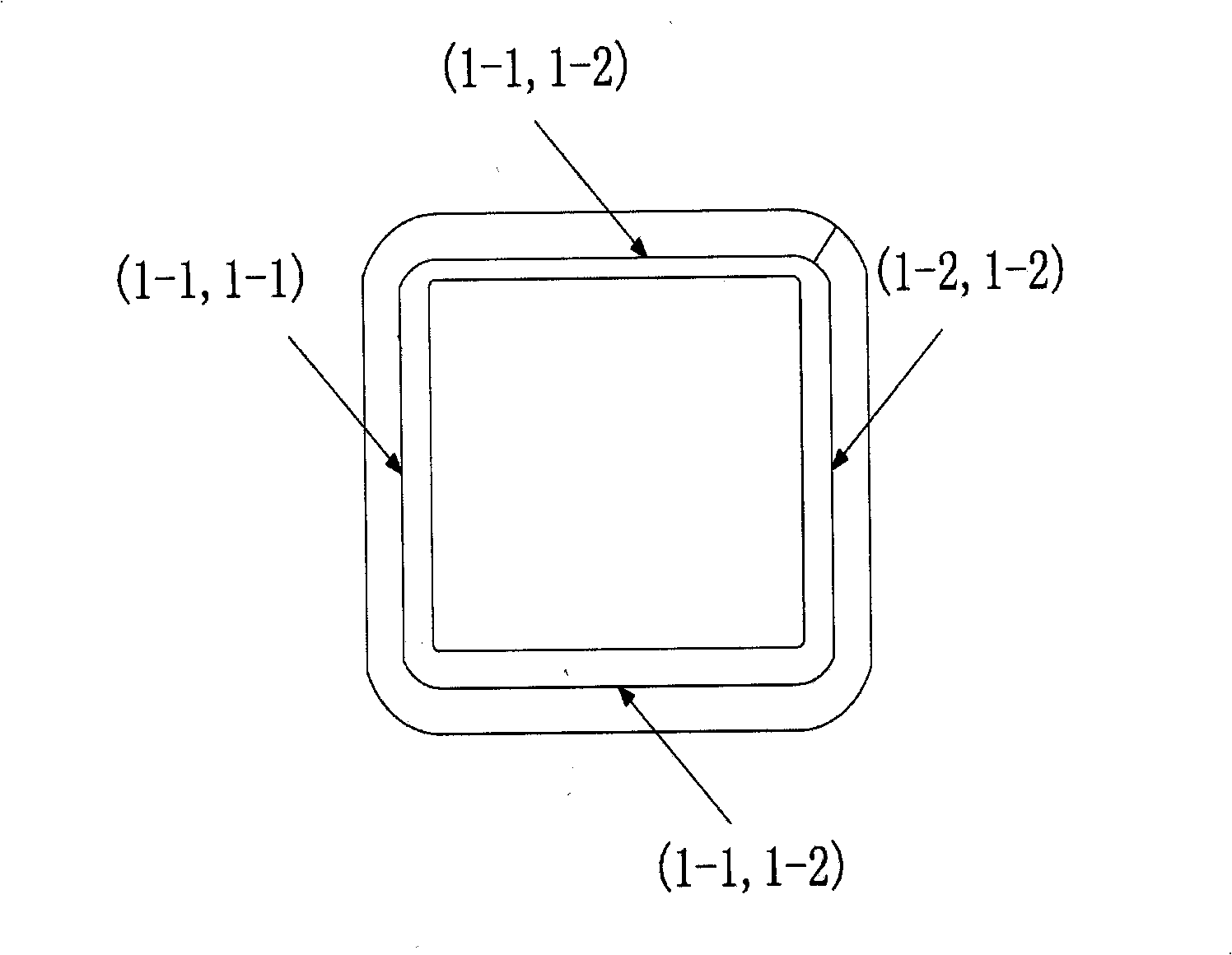

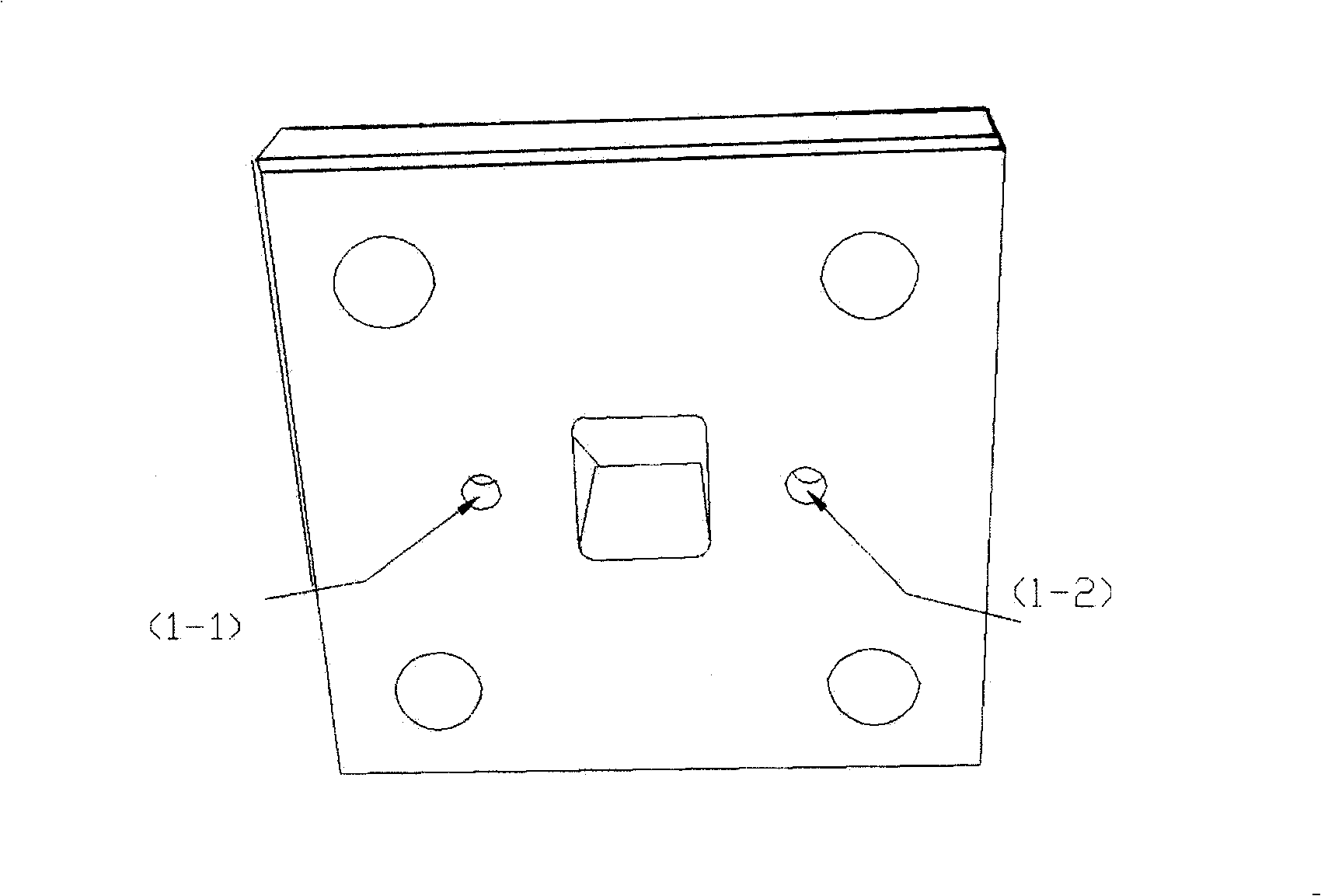

[0039] see figure 1 / 2, the mixed base material (base material) enters the 65 conical twin-screw extruder from the base material flow channel inlet (2) for extrusion molding, and its material flow direction is shown in the attached figure 1 , the extrusion process is as follows: host speed: 40~45r / min, feeding speed: 10~15r / min, melt pressure: 25~35MPa, barrel 1 zone: 175~170℃, barrel 2 zone: 175~ 170°C, barrel 3 zone: 165~160°C, barrel 4 zone: 145~140°C, confluent core: 165~160°C, mold zone: 180~190°C.

[0040] (Note: Technical parameters of the host: screw diameter: 65 / 132, effective length of the screw: 1440mm, special extrusion molding equipment for rigid PVC pipes, doors and windows)

[0041] Co-extrusion machine extrusion process:

[0042] Use a single-screw extruder to co-extrude a layer of 0.2-0.3mm hard PVC fabric on the surface of the main profile (base material). fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com