Controller and controlling method for non-bearing permanent magnet synchronous electric motor

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., and can solve the problem of limiting suspension force control accuracy and dynamic response performance, and inverter capacity utilization. High, difficult to achieve the control effect and other problems, to achieve the effect of excellent dynamic and static performance, excellent motor performance, fast speed response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

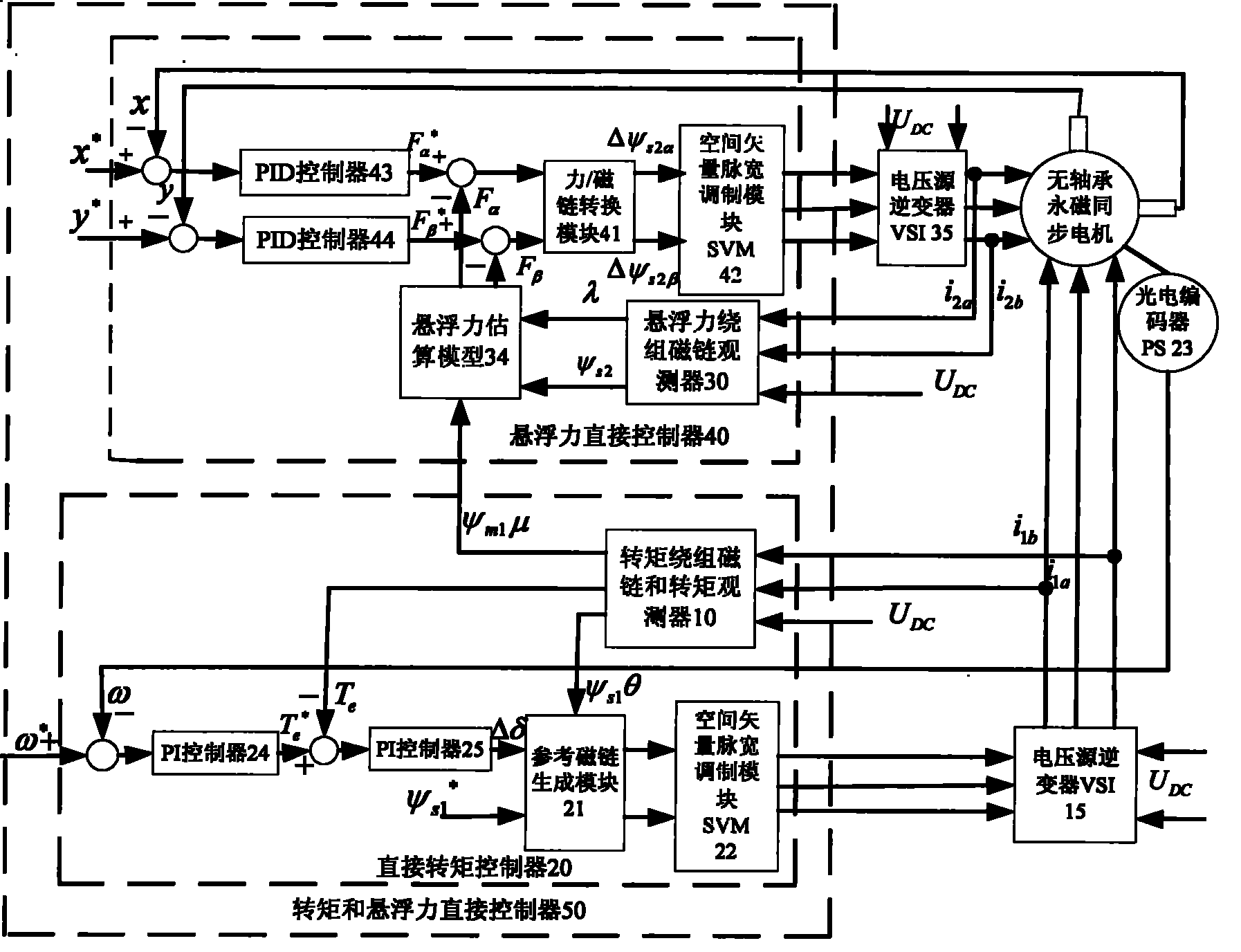

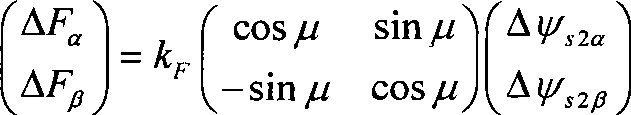

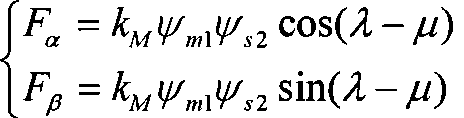

[0034] The embodiment of the present invention is: based on the prototype body of the bearingless permanent magnet synchronous motor, the direct control system of torque and levitation force is equivalent to two subsystems of direct control of torque and direct control of levitation force. For the torque direct control subsystem, construct a double closed loop with speed and torque consisting of two PI controllers, torque winding flux linkage and torque observer, reference flux linkage generation module and space vector pulse width modulation module SVM The direct torque control system, first use the torque winding flux and torque observer to obtain the torque winding flux and torque information required by the direct torque control; then the observed torque winding real-time flux and torque The torque information is applied to the direct torque controller to generate the switching signal of the torque winding control voltage source inverter, and drive the inverter to directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com