Salt taste additive agent, low-sodium salt taste agent and preparation thereof

A technology of additives and salty agents, applied in food preparation, application, food science, etc., to achieve the effect of protecting blood vessel walls, pure taste, and reducing the risk of stroke and heart disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 3.88 lbs of MgCl 2 ·6H 2 O, 0.78 lb NH 4 Cl, 0.36 lbs KCl mixed, adding 0.86 liters of water to form a slurry. The slurry is continuously stirred and heated to 100°C. The slurry is boiled continuously at standard atmospheric pressure for about 30 minutes, and about half of the water is distilled from the mixture. Using a centrifuge to further concentrate the mixture and separate other moisture, the moisture content of the mixture after the separation should be below 6%. Put the mixture after separating the water evenly into the fluidized bed drier, the temperature in the drier is 78-80°C, and add 0.2-0.3% anti-caking agent silicon dioxide immediately after complete drying. During the filtration process, the yield will be about 90% of the theoretical value and the filtrate can be recycled. The finished product additive that will make is measured, and the result is as follows:

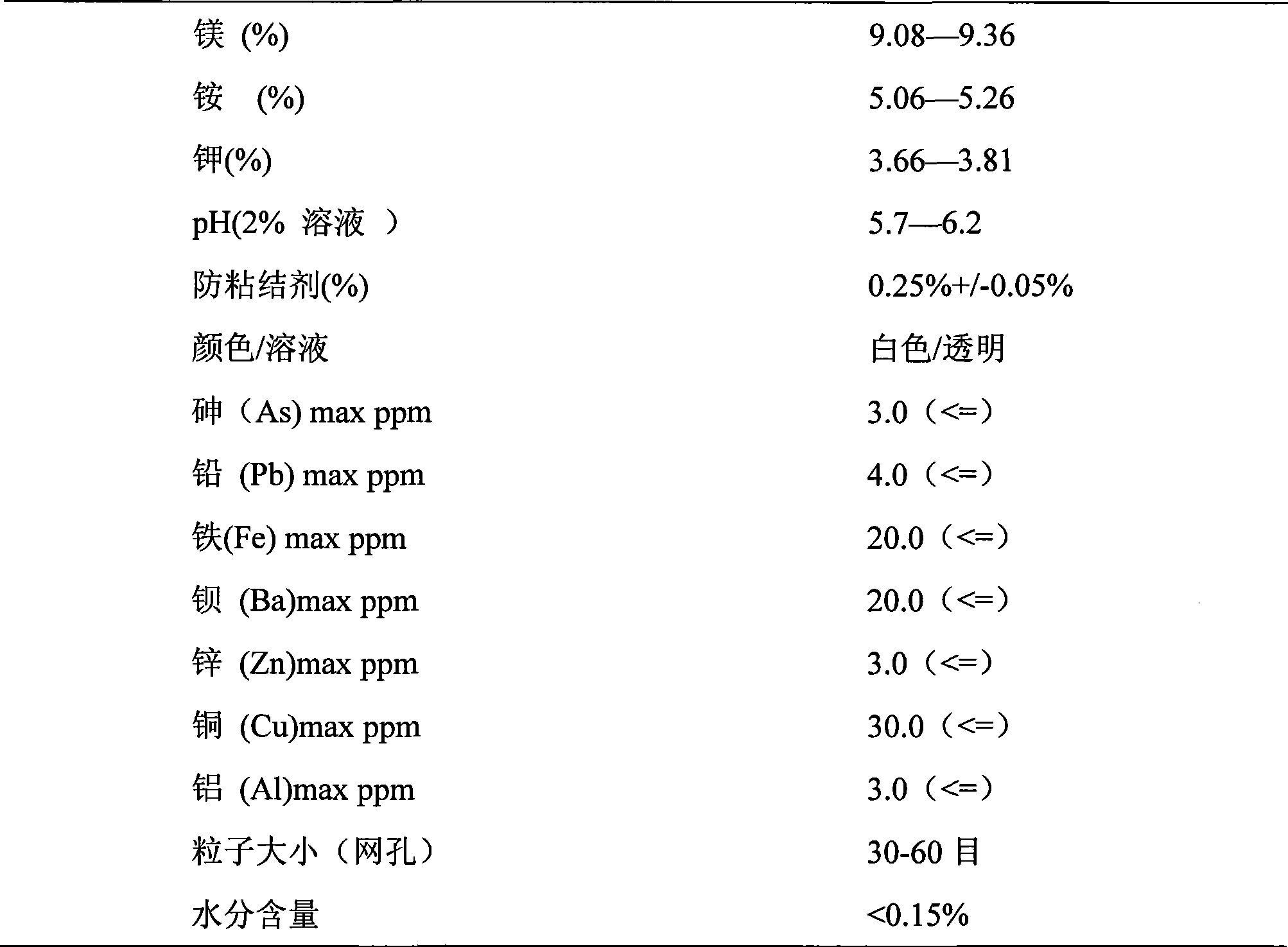

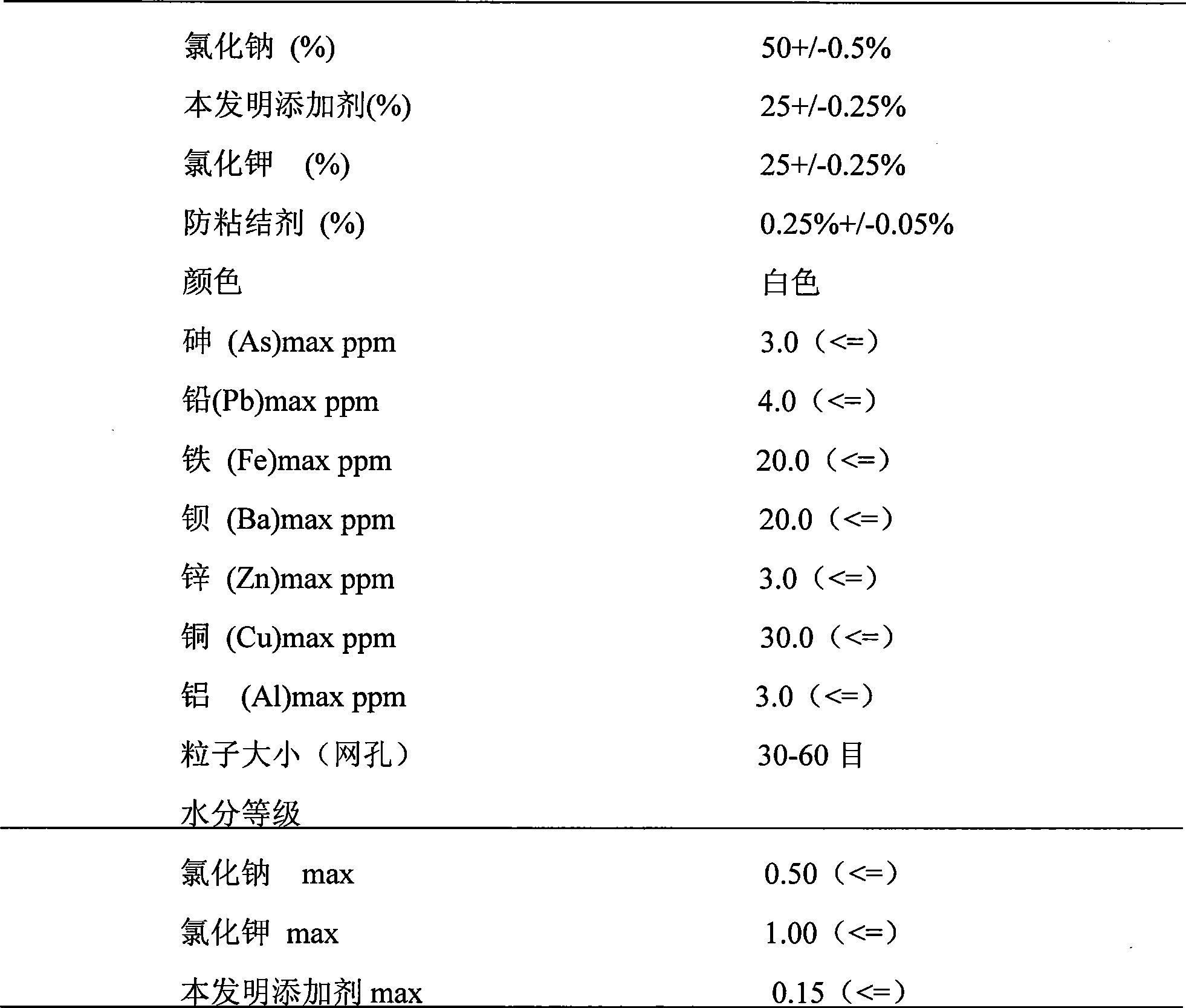

[0022] Table 1

[0023]

Embodiment 2

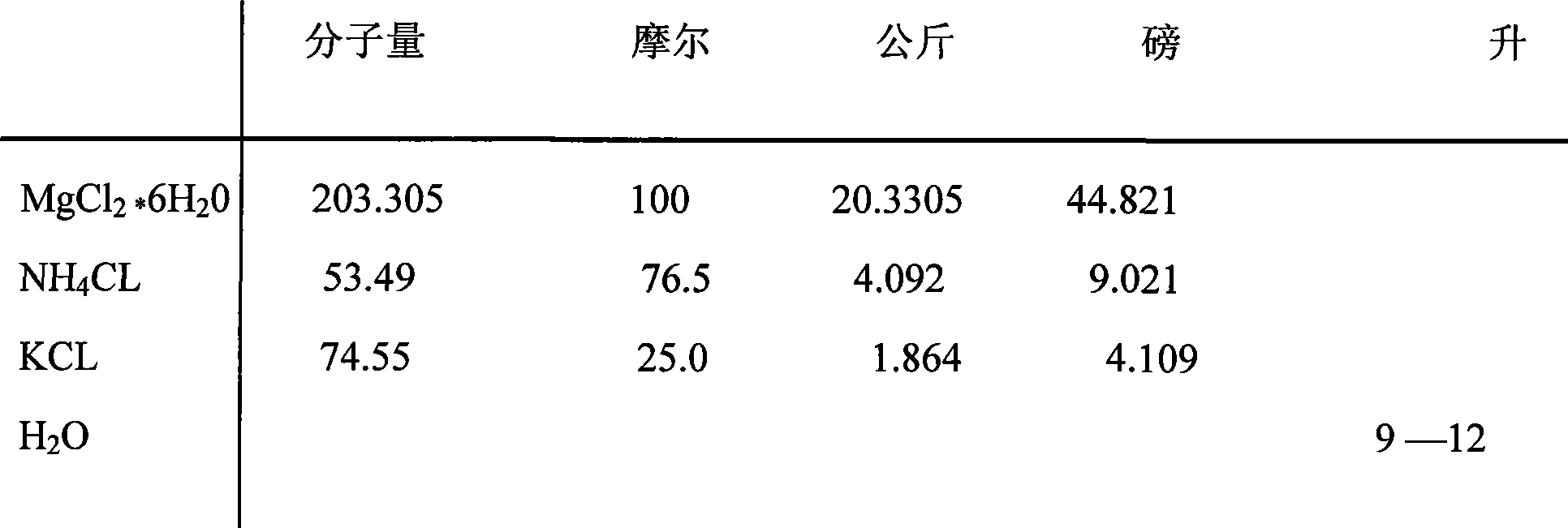

[0025] Taking the range of 100 moles as an example, this example is calculated in kilograms and pounds. The conversion index between kilograms and pounds is 1 kilogram = 2.2046 pounds. Production recipes can be divided or multiplied accordingly.

[0026] Material Note: Must be non-corrosive material

[0027]

[0028] Note: Chemical Molecular Weight (FM)

[0029] ●MgCl 2 x 6H2O=203.305

[0030] ●NH 4 CL=40.228[53.49 X 0.75]

[0031] ● KCL=18.638[74.55 X 0.25]

[0032] Total = 262.061 = total molecular weight

[0033] The whole process of salty additive manufacturing:

[0034] 1) All material suppliers must be approved by Shanghai Mingtai Company and meet the required product quality standards for food-grade materials; 2) Ammonium chloride (NH 4 Cl) and potassium chloride (KCl) and magnesium chloride hexahydrate MgCl 2 ·6H 2 O was added together and stirred well to form a mixture (Note 1);

[0035] 3) Gradually add water to the mixture in the reactor and keep stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com