Method for preparing passion flower fruit juice beverage

A passionflower and fruit juice technology, applied in food preparation, application, food science and other directions, to achieve the effects of reducing damage, reducing staleness, and eliminating the need for subsequent separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

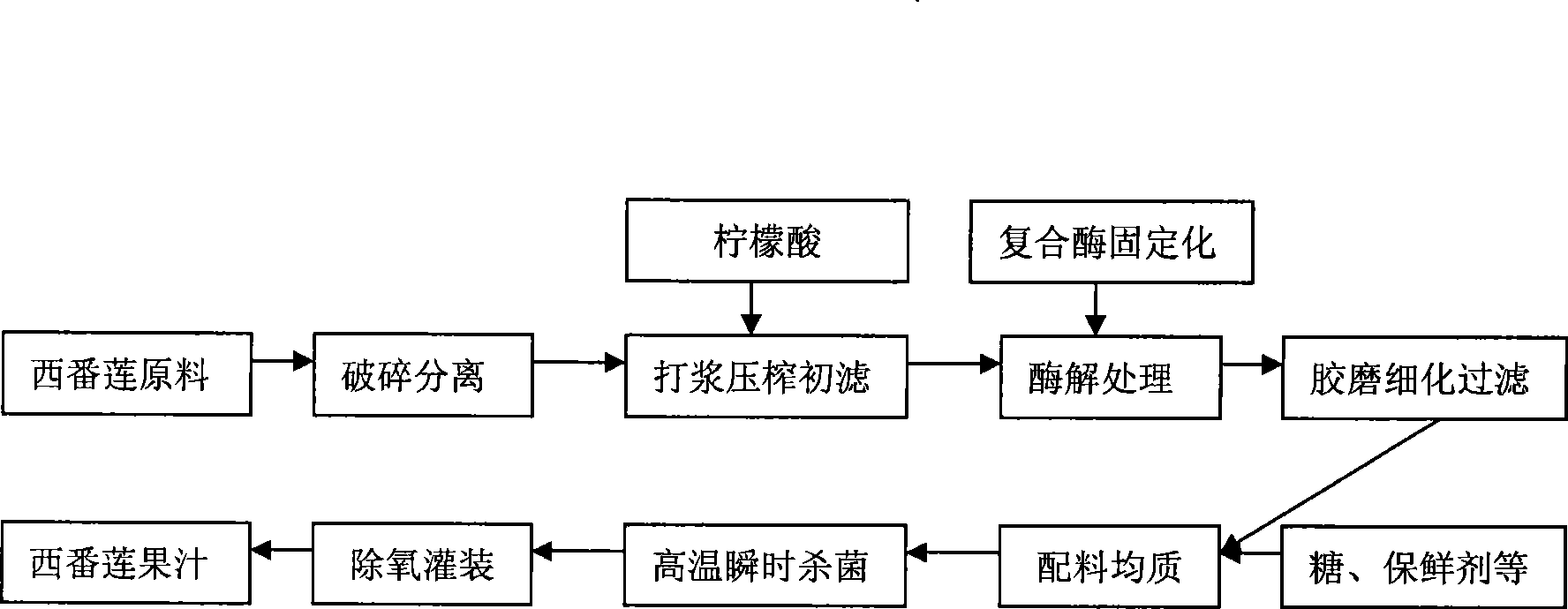

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: adopt ripe moderate, no damage by disease and insect, no rotten passion fruit fresh fruit is raw material, through cleaning, check selection, get passion fruit pulp 200kg, add water 60kg beating, add citric acid 0.35kg when beating, stir and heat To 60 DEG C, heat preservation and leaching for 30 minutes to obtain fruit pulp, then press and filter the fruit pulp to obtain about 185kg of passion fruit juice. In an environment with a temperature of 30-50°C and a pH value of 4-5, pass through an enzymolyzer at a flow rate of 160 l / h, filter after ultrafine treatment, and then add sucrose (1.5%) and fructose (2%); Fructose syrup (1%); L-cysteine (0.02%), ascorbic acid (0.08%), nisin: 0.001% and licorice extract 0.05%, after homogenization, the passion fruit fruit juice of preparation is dissolved Roll for ultra-high temperature instant sterilization, sterilization temperature (120°C), sterilization time 5 seconds; then fill with carbon dioxide gas to remove ...

Embodiment 2

[0040] Embodiment 2: adopt ripe moderate, no damage by disease and insect, no rotten passion fruit fresh fruit is raw material, through cleaning, check and select, get passion fruit pulp 200kg, add 80kg water, citric acid 0.45kg, squeezing, beating, stir and heat To 55 DEG C, heat-preserving and leaching for 30 minutes and squeezing to obtain fruit pulp, then filter the fruit pulp to obtain about 195kg of passion fruit juice. Under the condition of temperature 30~50 ℃ and pH value 4.5, passion fruit filtrate is that 180l / h passes through enzymolyzer with flow velocity, filters after ultrafine treatment, then adds sucrose (2%), fructose (7%) ); fructose syrup (2%); L-cysteine (0.01%), ascorbic acid (0.02%), nisin: 0.003% and licorice extract 0.1%, homogenized to the prepared Passiflora The juice is melted and rolled for ultra-high temperature instant sterilization, sterilization temperature (120°C), sterilization time 5 seconds; then filled with carbon dioxide gas to remove o...

Embodiment 3

[0041]Embodiment 3: adopt ripe moderate, no damage by disease and insect, no rotten passion fruit fresh fruit is raw material, through cleaning, inspection, get passion fruit pulp 200kg, add 100kg water, citric acid 0.5kg, squeezing, beating, stir and heat To 50 DEG C, insulated and extracted for 30 minutes and squeezed to obtain fruit pulp, and then the fruit pulp was filtered to obtain about 215kg of passion fruit juice. Under the condition of 45 ℃ of temperature and pH value 5, passiflora filtrate is 200l / h to pass through enzymolyzer with flow velocity, filter after ultrafine treatment, then add sucrose (3%), fructose (6%) ; Fructose syrup (1%); L-cysteine (0.05%), ascorbic acid (0.06%), nisin: 0.005% and licorice extract 0.2%, homogenized to the prepared passion fruit juice Melt and roll for ultra-high temperature instantaneous sterilization, sterilization temperature (130°C), sterilization time 3 seconds; then fill in carbon dioxide gas to remove oxygen from the juice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com