Integral step-by-step multiple-stage heat-preserving sintering process of metal porous membrane tube

A multi-stage heat preservation and metal porous technology, which is applied in the direction of semi-permeable membrane separation, membrane technology, filtration separation, etc., can solve the problems of deformed metal porous performance, sintering cracking, poor performance, etc., and achieve simple and reasonable process steps and easy operation and control , combined with a firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

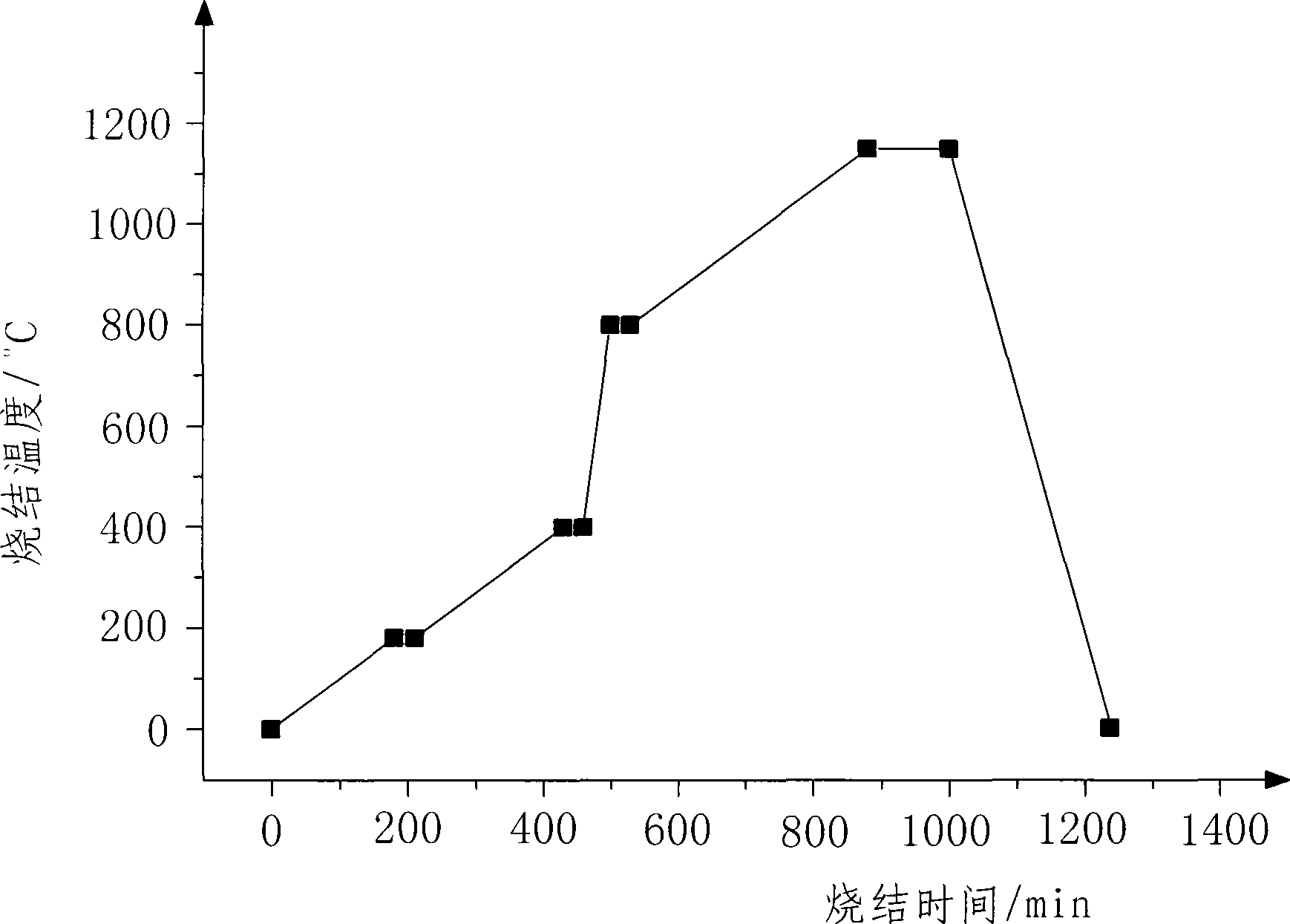

[0026] like figure 1 As shown, the overall step-by-step multi-stage heat preservation and sintering process of the metal porous membrane tube of the present invention comprises the following steps:

[0027] Step 1. Process the flange according to the inner diameter of the processed metal porous membrane tube blank, and assemble the two tightly. The metal porous membrane tube is composed of a porous support tube body and a metal film layer attached thereto , the metal film layer includes metal powder and sol dispersant and / or water. The metal porous membrane tube described in step 1 has an outer diameter of 50±5mm and an inner diameter of 44±4mm.

[0028] In this embodiment, the metal film layer is composed of stainless steel powder, polyvinyl alcohol and water, and the particle size of the stainless steel powder is -500 mesh. In addition, the outer diameter of the metal porous membrane tube is 50 mm, and the inner diameter is 44 mm.

[0029] Step 2: Furnace loading: First, ...

Embodiment 2

[0046] In this embodiment, the metal film layer is composed of stainless steel powder and paraffin substance, and the particle size of the stainless steel powder is 300 mesh to 400 mesh. In addition, the outer diameter of the metal porous membrane tube is 50 mm, and the inner diameter is 44 mm.

[0047] In this embodiment, 40° C. to 100° C. is the stage of paraffin softening and starting to decompose, and the heating rate is 2° C. / min. The early stage of volatilization of sol dispersant is the initial stage of paraffin decomposition and volatilization: the temperature rise ranges from 100°C to 180°C and the heating rate is 1°C / min, and 180°C is the temperature at which paraffin begins to volatilize; when the temperature rises to 180°C, after 30 minutes of heat preservation, Continue to sinter. The mid-stage of volatilization of the sol dispersant is the mid-stage of paraffin wax decomposition and volatilization: the temperature rise ranges from 180°C to 360°C and the temperat...

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that the metal film layer is composed of nickel powder, polyvinyl alcohol, water and other substances, and the particle size of the nickel powder is -500 mesh. In addition, the outer diameter of the metal porous membrane tube is 50 mm, and the inner diameter is 44 mm. All the other steps and relevant processing conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com