Carbon nano-tube microparticle supported palladium nano particle as well as preparation method and application thereof

A technology of carbon nanotubes and multi-walled carbon nanotubes, applied in organic chemical methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve difficult problems and achieve large pore capacity, The effect of high structural stability and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

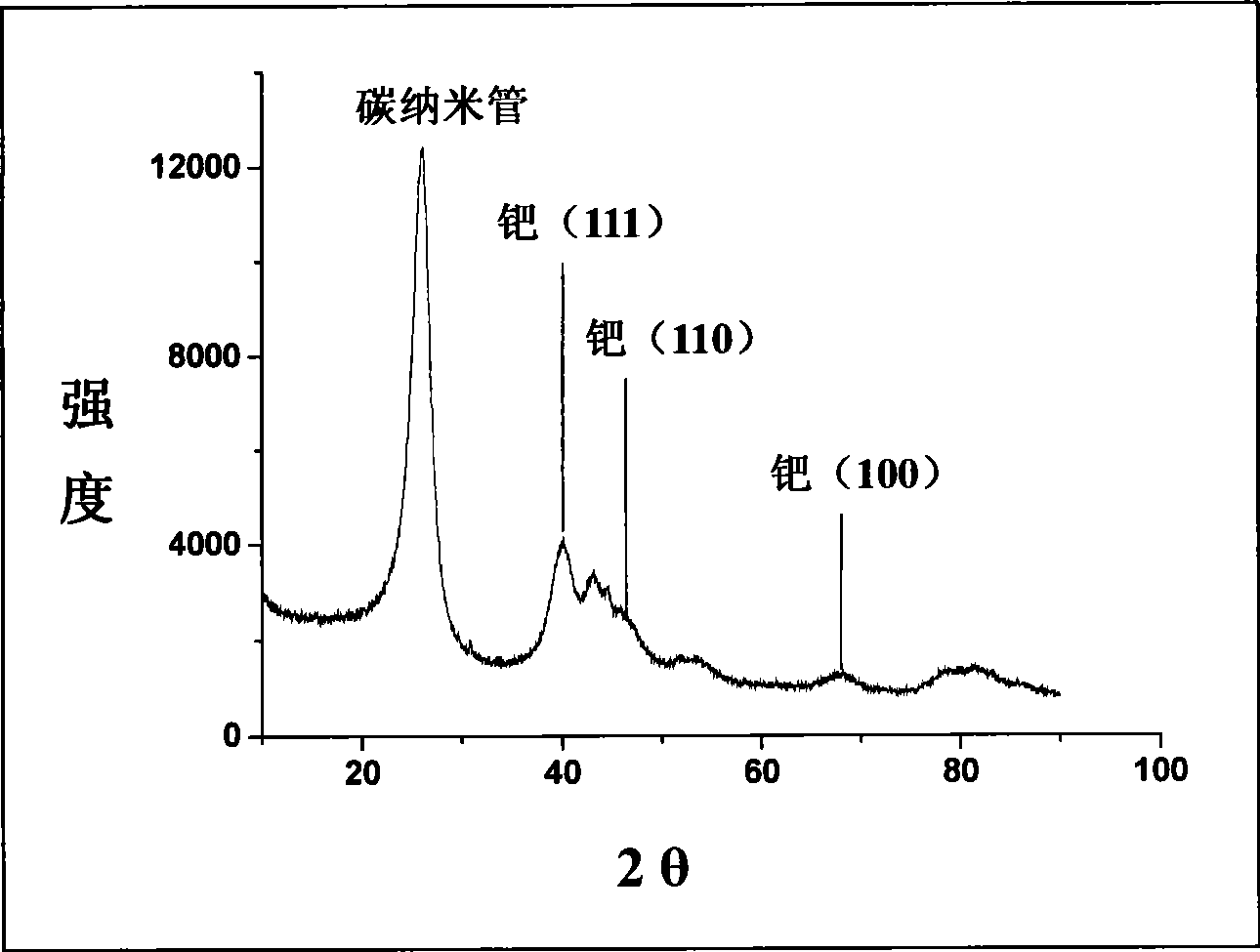

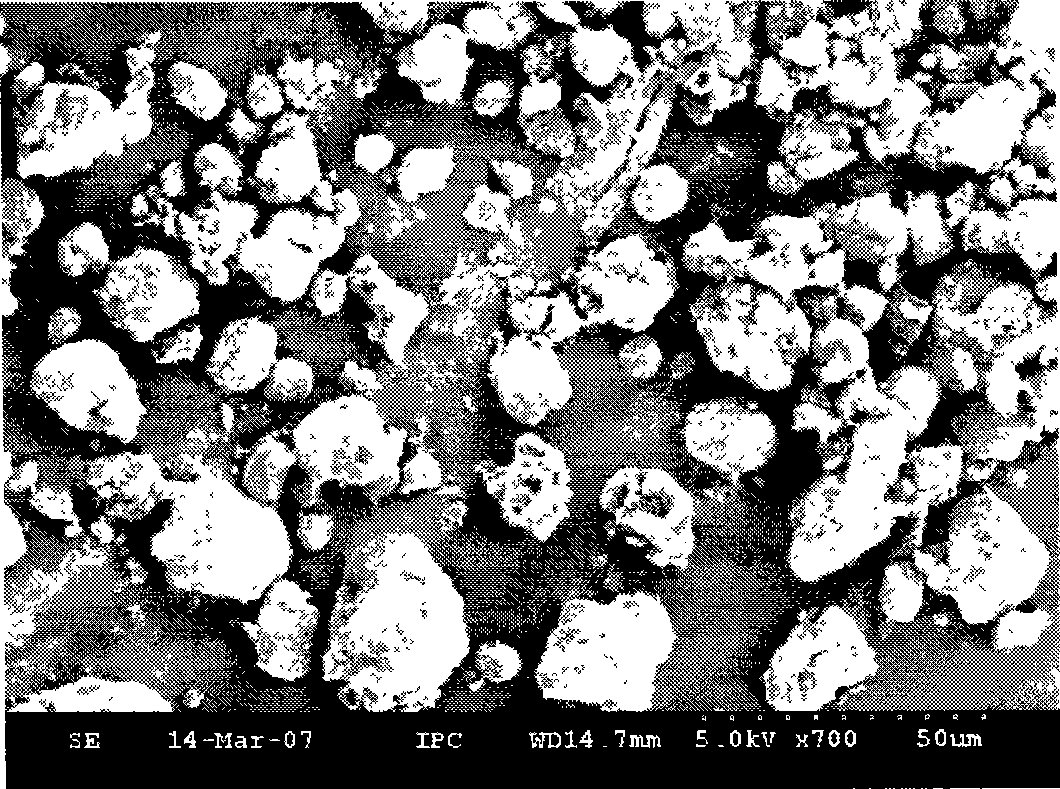

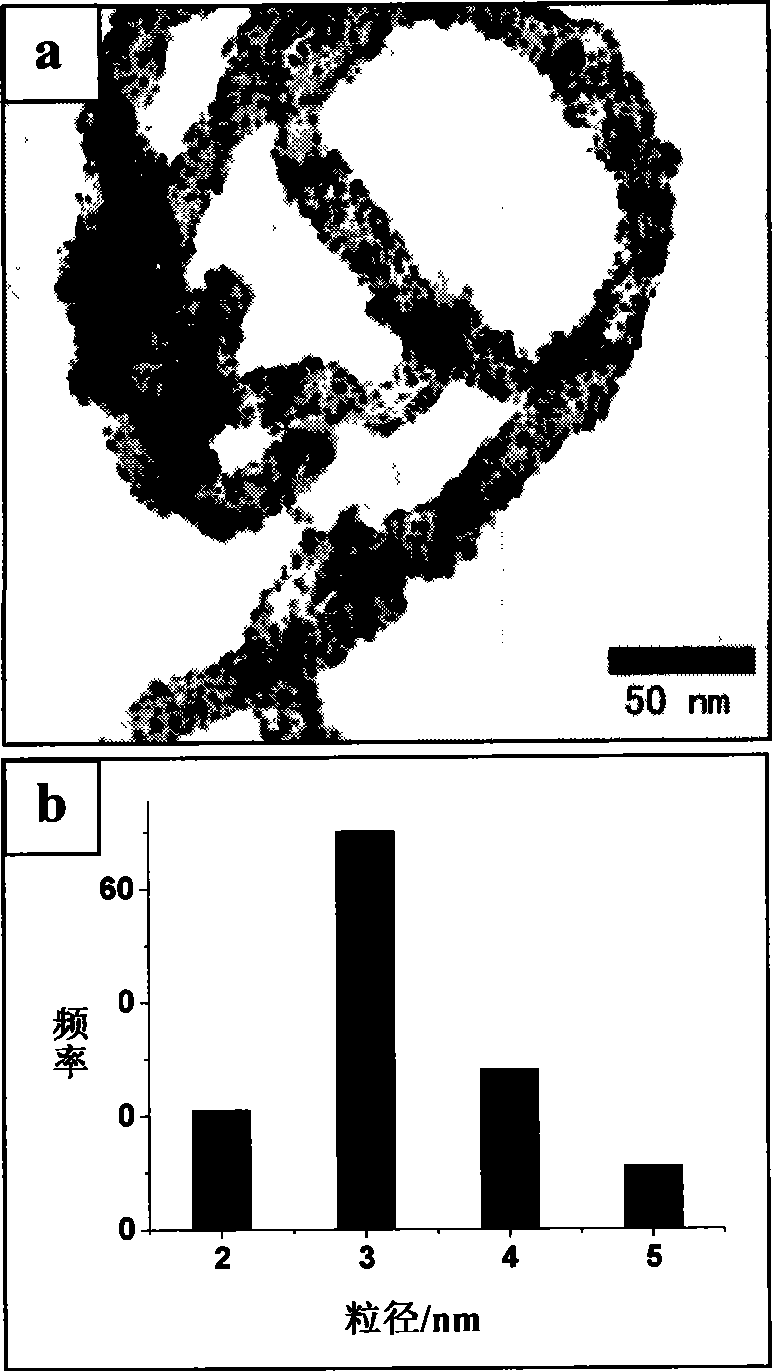

[0029] Add 5 mg of carbon nanotubes and 402 mg of sodium lauryl sulfate with a purity of not less than 99% to 20 ml of ethylene glycol, heat and stir for 30 minutes, then sonicate for 1 hour, and add 55 microliters of sodium chloropalladate aqueous solution dropwise (the concentration of sodium chloropalladate is 0.1 mol / liter), heated and stirred at 110°C for 3 hours. Take it out and let it stand for a period of time until solid precipitates appear, centrifuge at 4000 rpm for 10-15 minutes, then wash the sample with distilled water and ethanol, repeat 3-5 times. Finally, the prepared sample was vacuum-dried for more than 10 hours at 50-70° C. to obtain black carbon nanotube particles loaded with palladium nanoparticles, such as figure 2 shown. Take a small amount of dried sample and redisperse it in ethanol, ultrasonically disperse for 5 minutes under the ultrasonic conditions of 120W, 40KHz, spot the sample on the copper grid for transmission electron microscope, and then ...

Embodiment 2

[0031] Weigh 5 mg of carbon nanotube particles, add dropwise 60 microliters of sodium chloropalladate aqueous solution, and other conditions are the same as in Example 1, to obtain carbon nanotube particles loaded with palladium nanoparticles. Transmission electron micrographs show that the average particle size of the palladium nanoparticles is 3 nm.

Embodiment 3

[0033] Weigh 5 mg of carbon nanotube particles, add 500 mg of sodium lauryl sulfate, and other conditions are the same as in Example 1, to prepare carbon nanotube particles loaded with palladium nanoparticles. The average particle diameter of the palladium nanoparticles is 3 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com