Processing method for wastewater from cephalosporin synthesis pharmaceutical production

A technology for production wastewater and treatment methods, which is applied in the field of water treatment, can solve the problems of poor treatment effect of cephalosporin synthetic pharmaceutical production wastewater, and achieve the effect of good wastewater treatment effect, simple process and high treatment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

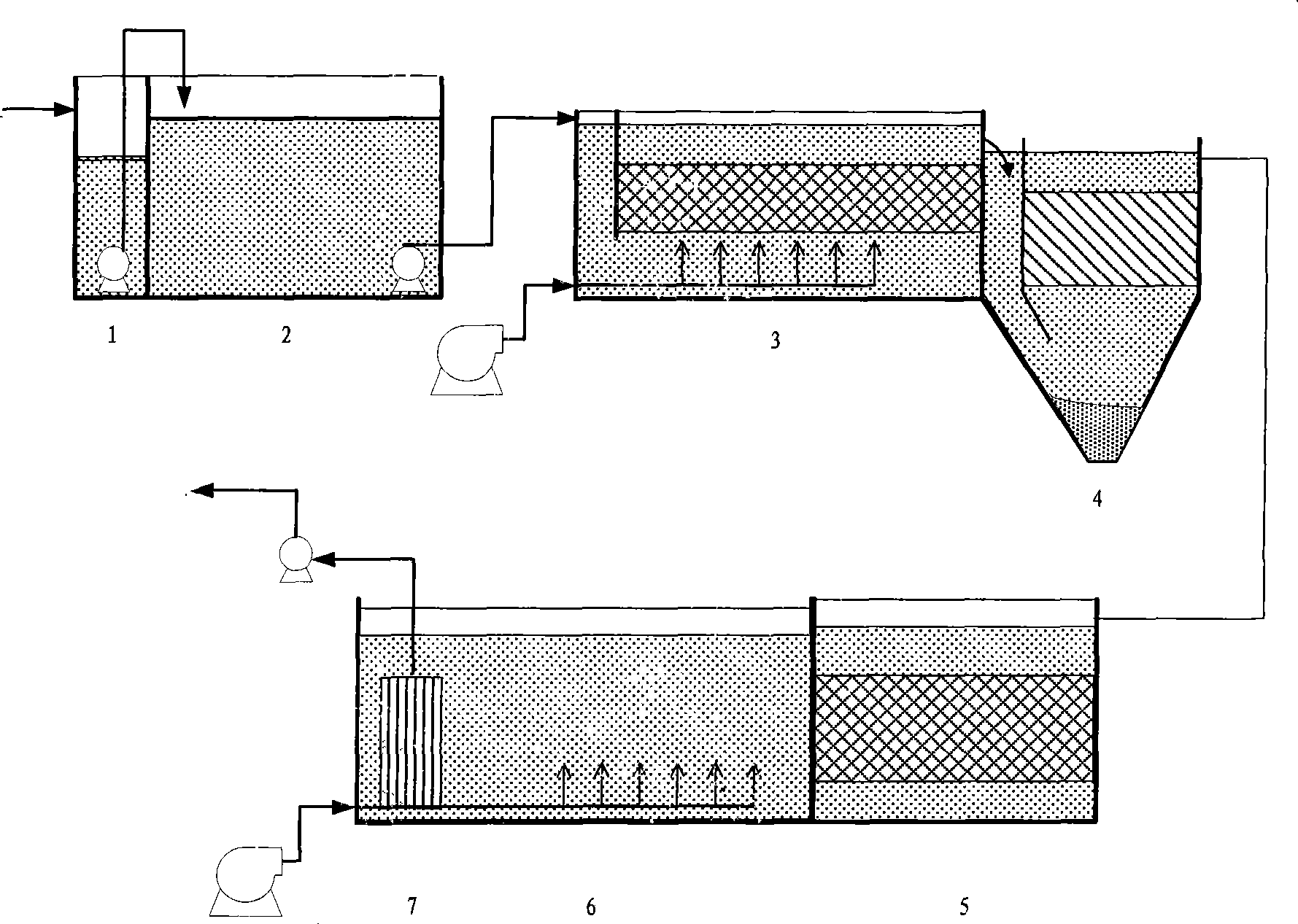

[0016] Cephalosporin synthetic pharmaceutical production wastewater 300m3 / d, incoming water COD 4000-7000mg / l, BOD5 50-300mg / l, after the adjustment tank balances the water quality and quantity and adjusts the pH value, aerobic biological treatment is carried out in the contact oxidation tank to remove biochemical Part of the organic matter with better properties. The hydraulic retention time of the contact oxidation tank is 19 hours, the volume load is 3.1kgCOD / m3.d, the effluent COD is 2000-3000mg / l, and the BOD5 is 20-230mg / l; The residence time in the bioreactor is 20 hours, the volume load is 4.5kgCOD / m3.d, the sludge concentration is 6-10g / l, the membrane flux is 10L / m2.h, and the membrane filtration resistance is less than 30kPa; the effluent COD≤ 100mg / l, BOD5≤10mg / l, SS below the detection limit, turbidity≤0.4NTU.

[0017] The ultrafiltration membrane in the membrane bioreactor is made of PVDF, the membrane flux is 10L / m2.h, the initial resistance of membrane filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com