An strain of low temperature leaching-ore bacteria and process for using the same for low temperature heap leaching of nickel sulfide ore

A technology for nickel sulfide ore and leaching bacteria, which is applied in the field of low-temperature leaching bacteria and the low-temperature heap leaching process for nickel sulfide ore, can solve the problems of poor leaching performance, heavy environmental pollution, arsenopyrite and the like

Active Publication Date: 2010-11-10

有研资源环境技术研究院(北京)有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The nickel grade of the ore to be processed is above 0.8%. Due to strict requirements on the quality of flotation concentrate, the processing process is long and complicated, and has disadvantages such as high cost, high energy consumption, and heavy environmental pollution, it is not suitable for processing nickel grade. Low-grade nickel sulfide ore below 0.8%

Among the proven nickel-cobalt mineral resources, most of the low-grade nickel sulfide ores with a nickel grade of less than 0.8% account for more than 50%, and most of the mines are located in low-temperature areas. It is uneconomical to use the existing traditional technology to mine. Benefits; if the existing normal-temperature bacteria and high-temperature bacteria are used for bioheap leaching, when the temperature is below 15°C, the activity of the leaching bacteria is not high, the leaching performance is poor, the leaching speed is slow, and the leaching cycle is long, which affects the metal leaching rate. There is also the disadvantage of high insulation cost, which virtually increases the production cost

For example, in the cold northeastern region of my country, the proven low-grade nickel sulfide deposits have a nickel grade of 0.1% to 0.5%, and the main nickel-containing minerals are pentlandite, purple sulfur nickelite, arsenite, etc. The main arsenic-containing minerals are arsenopyrite in addition to arsenic-nickel ore, which cannot be developed and utilized by the existing traditional dressing and smelting process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Login to View More

Abstract

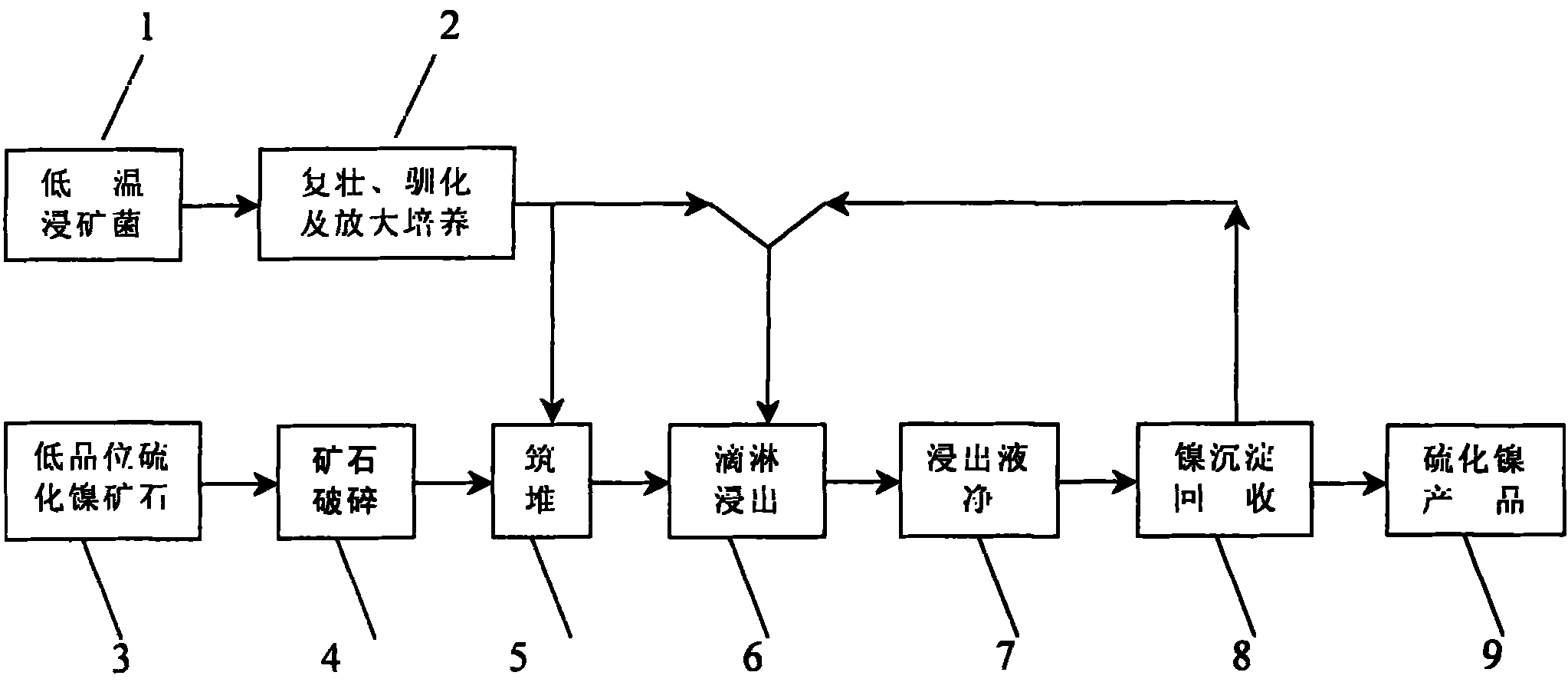

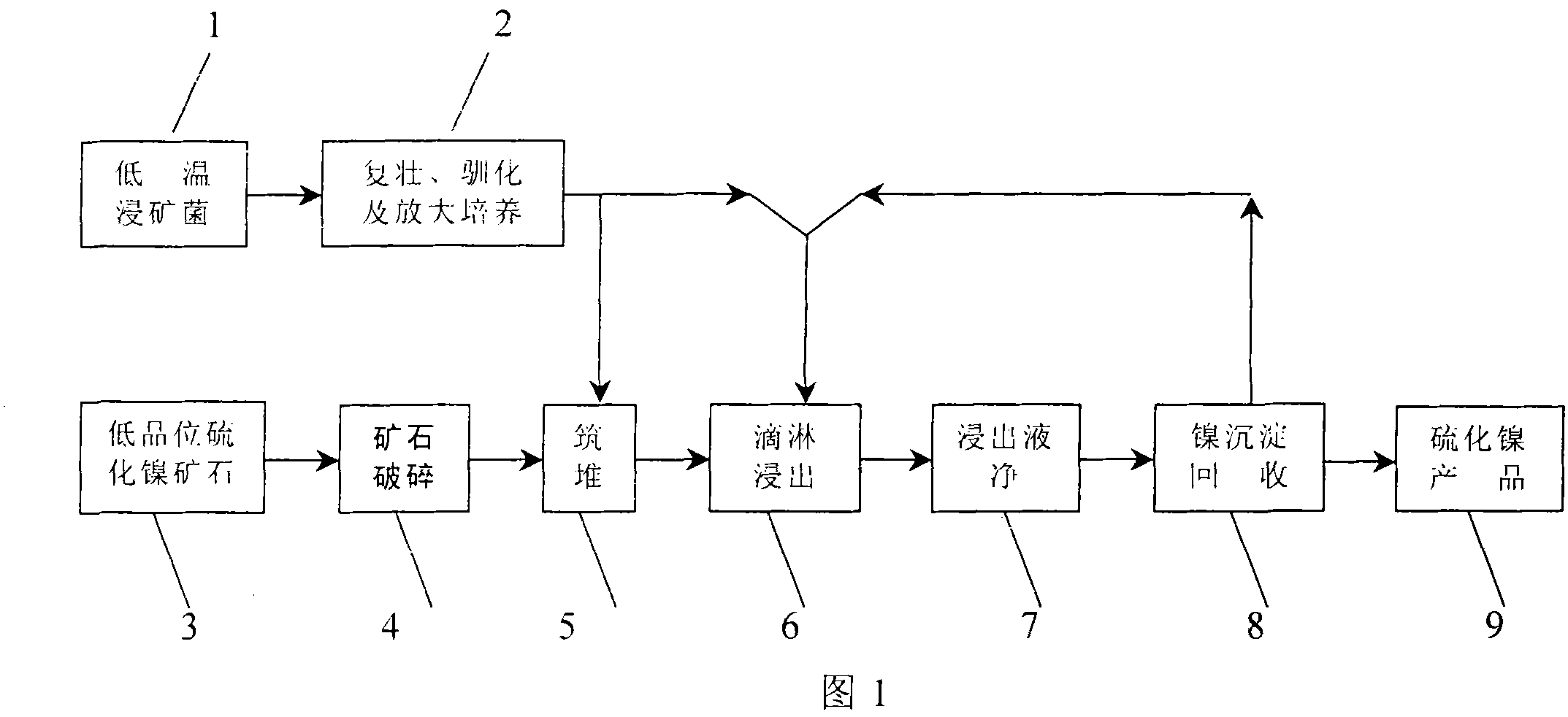

The invention provides a low-temperature mineral leaching bacterium and a low-temperature heap leaching technique of nickel sulfide ore that uses the low-temperature mineral leaching bacterium. The name of the low-temperature mineral leaching bacterium is Thiobacillus ferrooxidans Retech-L-I, the preservation registration number is CCTCC No. of M207157, the preservation date is October 16th, 2007, and the preservation unit is China Center for Type Culture Collection in Wuhan University. The low-temperature heap leaching technique of nickel sulfide ore comprises the working procedures of low-temperature mineral leaching bacterium rejuvenation, domestication and amplified cultivation, ore stacking, and spraying with a liquid containing the low-temperature mineral leaching bacterium, and a leaching liquid that is obtained by a leaching procedure is sent to working procedures of iron removing, arsenic removing and metal recycling. The low-temperature heap leaching technique of nickel sulfide ore that uses the low-temperature leaching bacterium has the advantages that the technique not only is environment-friendly, but also can be used for exploiting low-grade nickel ore resources thatcannot be utilized by traditional picking metallurgy techniques, and the technique is particularly applicable to the exploit of nickel sulfide ore resources in highly cold low-temperature areas that cannot realize the engineering of biological normal temperature and high temperature heap leaching, enlarges the utilization range of nickel ore resources, and raises the synthetic nickel utilization rate.

Description

A low-temperature ore leaching bacteria and its low-temperature heap leaching process for nickel sulfide ore technical field The invention relates to a strain of low-temperature ore leaching bacteria and its low-temperature heap leaching process for nickel sulfide ore, in particular to a strain of low-temperature ore leaching bacteria and its low-temperature biological heap leaching for extracting metallic nickel from nickel sulfide ore heap leaching craft. Background technique The traditional processing technology of nickel sulfide ore is ore crushing, ore grinding, flotation, and flotation concentrate pyromelting. The nickel grade of the processed ore is above 0.8%. Due to strict requirements on the quality of the flotation concentrate, the processing process is long and complicated, and there are disadvantages such as high cost, high energy consumption, and heavy environmental pollution, so it is not suitable for processing nickel grades. Low-grade nickel sulfide ore b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12N1/20C22B3/18

CPCY02P10/20

Inventor 温建康刘学舒荣波宋永胜

Owner 有研资源环境技术研究院(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com