Artificial soil, and formulating method and use thereof

A technology for artificial soil and fly ash, applied in the application, soil conditioning materials, chemical instruments and methods, etc., to achieve the effects of sufficient supply, economical consumption, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The artificial soil is composed of fly ash with a water content of 7.54% and municipal sludge with a water content of 81.01%.

[0018] Preparation method: air-dry the collected fly ash with a water content of 7.54% in a natural state to a water content of 1-5%, and at the same time air-dry the collected sludge with a water content of 81.01% in a natural state to a water content of 55- 60%, and then mix the two by weight fraction fly ash: sludge = 1:1 to obtain (see Table 1).

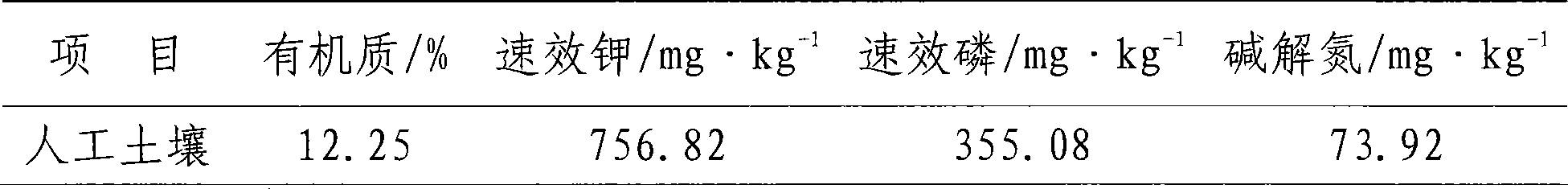

[0019] Table 1 Nutrient content of fly ash passivation sludge artificial soil

[0020]

[0021] It shows that organic matter and available nitrogen, phosphorus and potassium nutrient contents in the artificial soil of the present invention all belong to high fertility level. The fly ash is the newly discharged fly ash collected from the ash storage tank of the No. 2 Iron and Steel Electric Power Plant of Liaoning Province, and the sample is collected by random sampling method; the sludge is co...

Embodiment 2

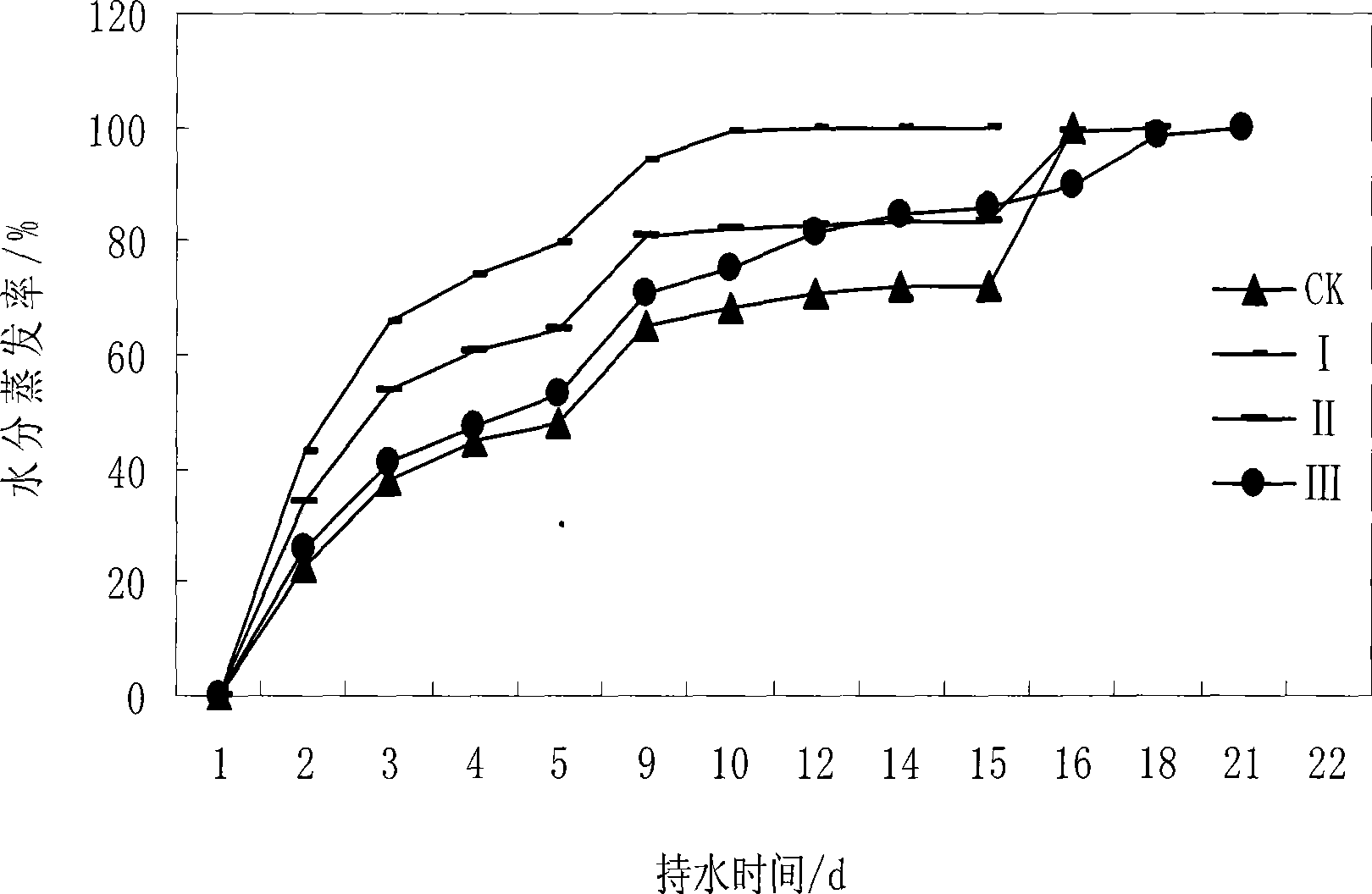

[0023] The collected raw materials, fly ash and municipal sludge, are air-dried in a natural state, and other treatment methods such as high-temperature drying are not used. When the sludge is air-dried until the water content is 55-60%, and the water content of the fly ash is 1-5%, the fly ash and the sludge are mixed in a weight ratio of 1:1, 3:1 and 2:1. Treatment III , I, II. III, I, II three kinds of artificial soil saturated water ratios are 66.55%, 58.98%, 61.9%; The water holding time of artificial soil of the present invention is 21 days, 14 days and 18 days; Days evaporated 26.17%, 42.73% and 34.24%. (see figure 1 ).

Embodiment 3

[0025] Air-dry the collected fly ash with a water content of 8-10% to a water content of 3-5%, and at the same time air-dry the collected sludge with a water content of 90-95% to a water content of 60%, and then combine the fly ash with The sludge is mixed at a weight ratio of 1:2 and 3:2 to obtain artificial soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com