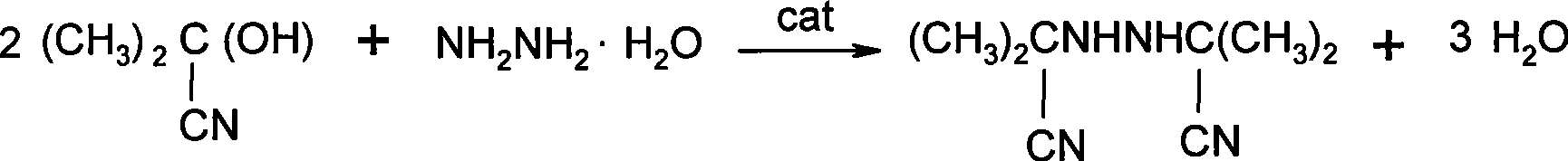

Method for synthesizing bis-isobutyronitrile hydrazine

A technology of diisobutyronitrile and synthesis method, which is applied in chemical instruments and methods, preparation of carboxylic acid nitrile, preparation of organic compounds, etc. Quality and other problems, to achieve the effect of improving the reaction yield, reducing the amount of addition, and expanding the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The preparation of embodiment 1 diisobutyronitrile hydrazine

[0013] In a 500ml flask, add 129 grams (1.50 moles) of 98.9% acetone cyanohydrin, 0.2 grams (0.00061 moles) of 98% tetrabutylammonium bromide and 50 grams (2.78 moles) of water. Concentration is 47.5 grams (0.76 mol) of industrial hydrazine hydrate of 80%. After the dropwise addition was completed, the temperature was raised to 60° C. and kept for 3 hours. Then the reactant was cooled to 5° C. to precipitate a solid, which was filtered and dried under reduced pressure (vacuum degree: 0.098 MPa) at room temperature for 8 hours to obtain 124.0 g of white crystalline diisobutyronitrile product. According to gas chromatography analysis, the purity of diisobutyronitrile hydrazine is 98.7%, and the reaction yield is 98.23% (calculated in acetone cyanohydrin).

[0014] The spectral analysis of product diisobutyronitrile hydrazine is as follows:

[0015] Infrared absorption spectrum characteristic frequency (cm ...

Embodiment 2

[0017] The preparation of embodiment 2 diisobutyronitrile hydrazine

[0018] In a 500ml flask, add 129 grams (1.50 moles) of 98.9% acetone cyanohydrin, 1 gram (0.00894 moles) of 98% tetramethylammonium chloride and 45 grams (2.5 moles) of water. Concentration is 48 grams (0.767 mol) of industrial hydrazine hydrate of 80%. After the dropwise addition was completed, the temperature was raised to 70° C. and kept for 4 hours. Then the reactant was cooled to 5° C. to precipitate a solid, filtered, and dried under reduced pressure (0.098 MPa) at room temperature for 10 hours to obtain 124.5 grams of a white crystalline diisobutyronitrile product, which was analyzed by gas chromatography. The purity of nitrile hydrazine is 98.5%, and the reaction yield is 98.42% (calculated in acetone cyanohydrin).

Embodiment 3

[0019] The preparation of embodiment 3 diisobutyronitrile hydrazine

[0020] In a 500ml flask, add 129 grams (1.50 moles) of 98.9% acetone cyanohydrin, 0.5 grams (0.00296 moles) of 98% tetraethylammonium chloride and 70 grams (3.89 moles) of water. 99 grams (0.791 moles) of industrial hydrazine hydrate with a concentration of 40%. After the dropwise addition was completed, the temperature was raised to 65° C. and kept for 5 hours. Then the reactant was cooled to 5° C., a solid was precipitated, filtered, and dried under reduced pressure (0.098 MPa) at room temperature for 9 hours to obtain 123.8 grams of a white crystalline diisobutyronitrile product, which was analyzed by gas chromatography. The purity of nitrile hydrazine is 99.1%, and the reaction yield is 98.47% (calculated in acetone cyanohydrin).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com