Y2O3-Gd2O3 system composite rare earth-molybdenum electron emission material and preparation method thereof

An electron emission material, y2o3-gd2o3 technology, applied in the direction of secondary electron emission electrode, light-emitting cathode manufacturing, discharge tube main electrode, etc., can solve problems such as poor electron emission performance, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

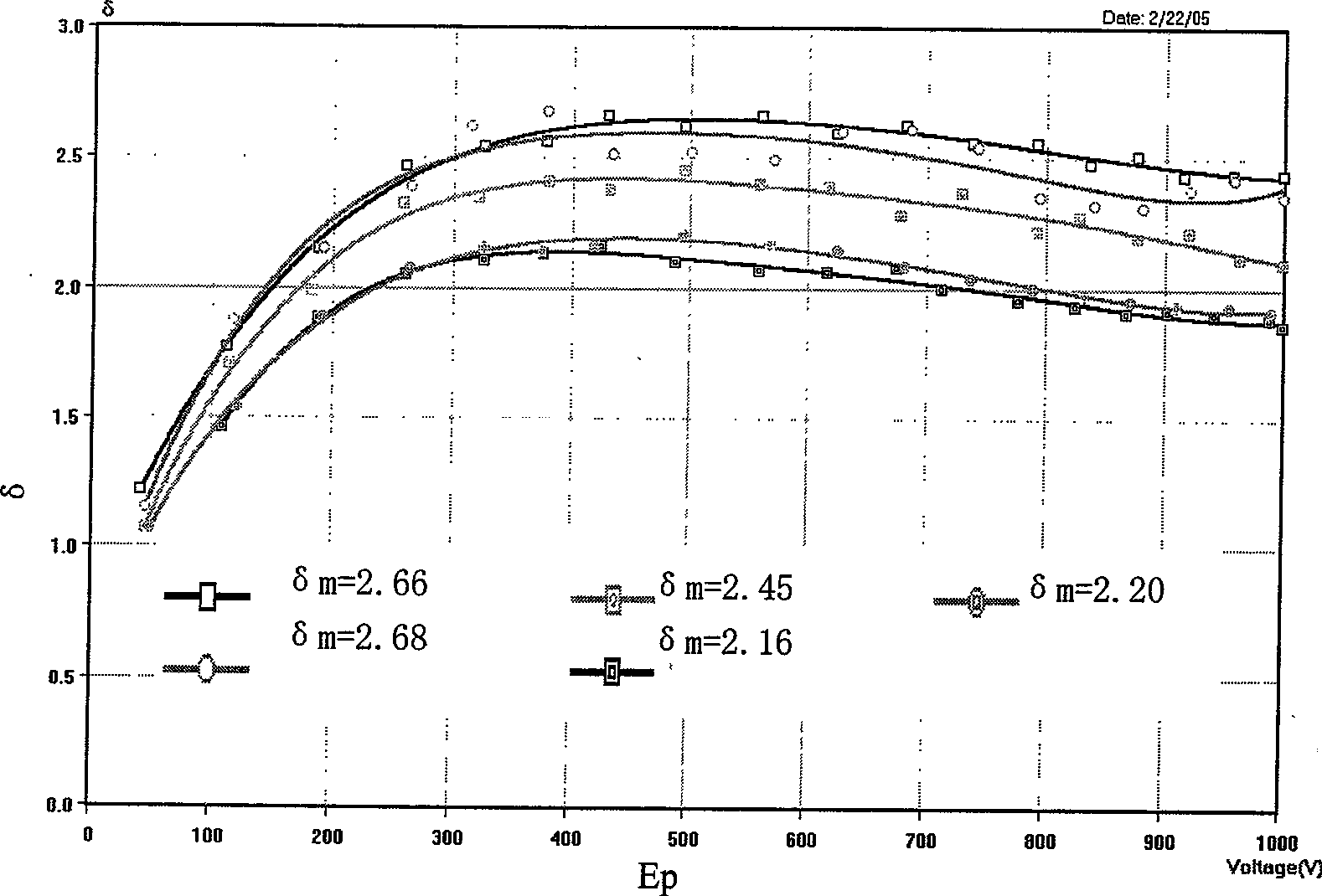

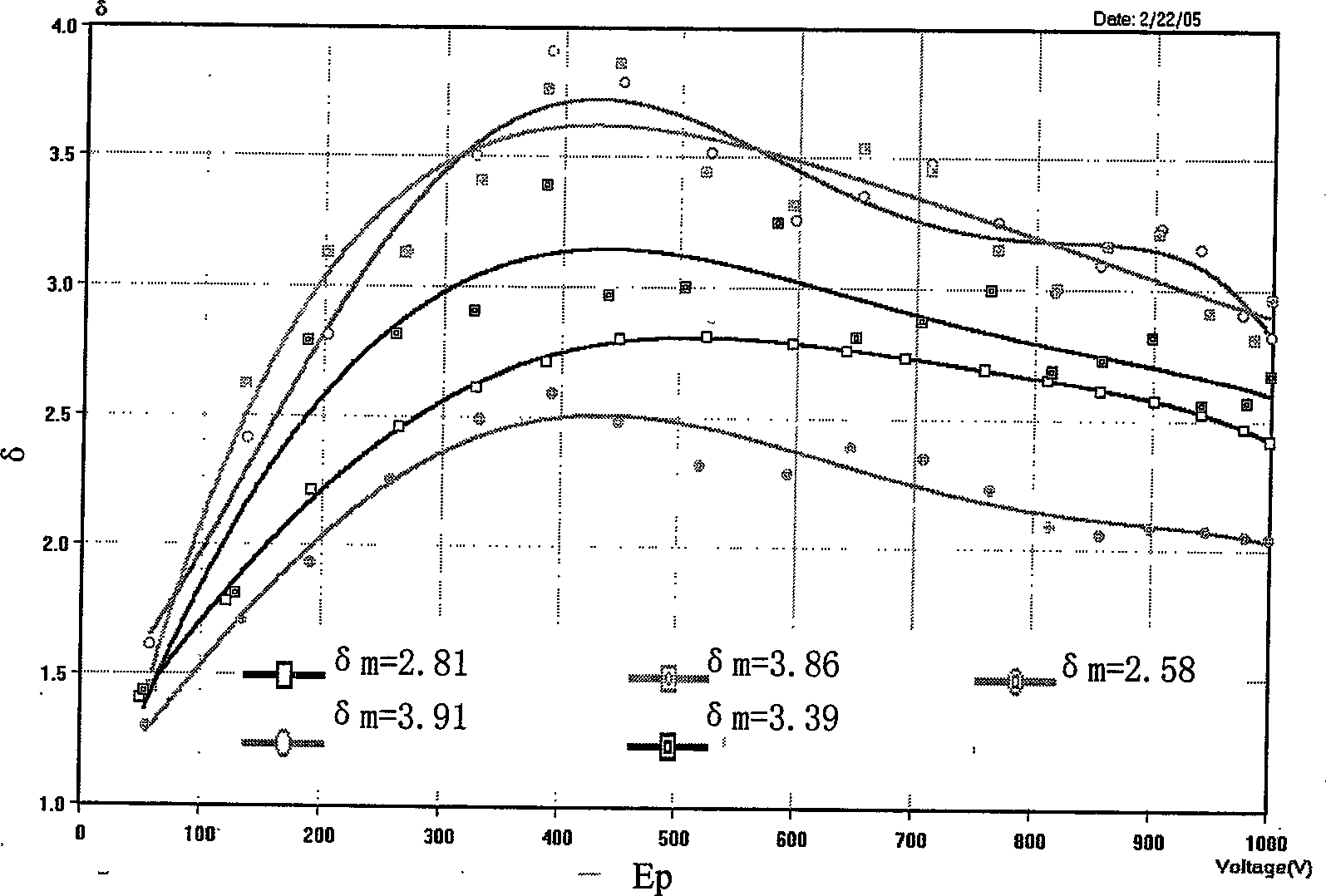

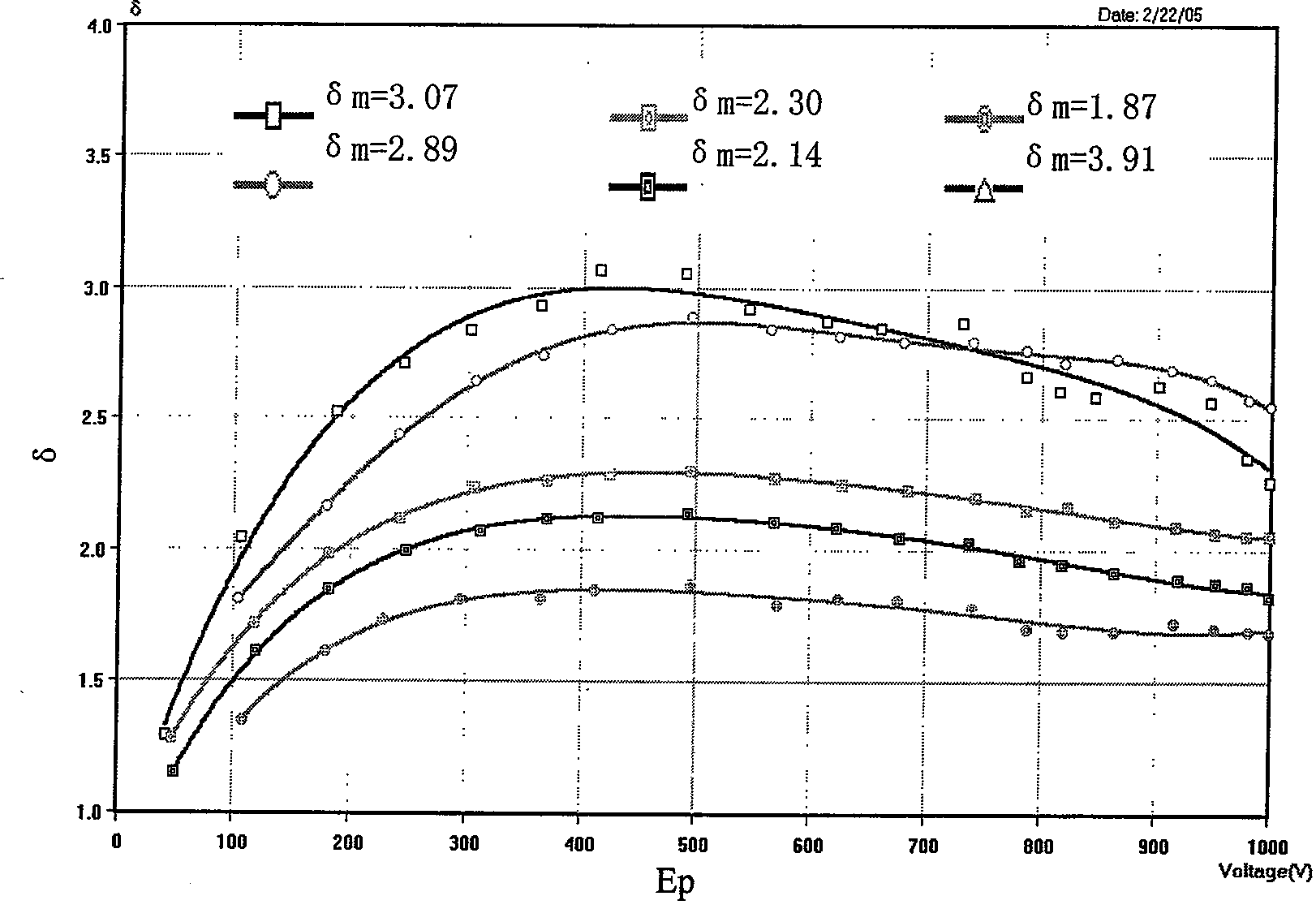

Image

Examples

Embodiment 1

[0023] (1) Add 64.6634 grams of Y(NO 3 ) 3 , 22.9140 grams of Gd(NO 3 ) 3 Respectively dissolve in absolute ethanol, and filter the solution after it is completely dissolved. Weigh 120.0235 grams of molybdenum trioxide powder and mix with the filtered nitrate solution, and heat it in a water bath at 80°C, stirring continuously until the liquid is completely evaporated.

[0024] (2) The powder obtained after evaporation is decomposed at 500°C in an air atmosphere until the nitrate is completely decomposed, and the N element in the powder is completely removed.

[0025] (3) The powder is crushed, sieved, and then the powder is reduced in a hydrogen atmosphere. The reduction is carried out in two steps. First, it is kept at 500°C for 2 hours, and then the temperature is raised to 900°C for 2 hours, and then cooled in the furnace. The reduced powder is pressed and sintered into a rare earth-molybdenum secondary electron emission material embryo. The embryo body is machined into rare e...

Embodiment 2

[0027] (1) Add 24.2488 grams of Y(NO 3 ) 3 , 51.5565 grams of Gd(NO 3 ) 3 Respectively dissolve in absolute ethanol, and filter the solution after it is completely dissolved. Weigh 120.0235 grams of molybdenum trioxide powder and mix with the filtered nitrate solution, and heat it in a water bath at 100°C, stirring continuously until the liquid is completely evaporated.

[0028] (2) Decompose the powder obtained after evaporation at 550°C in an air atmosphere until the nitrate is completely decomposed, and the N element in the powder is completely removed.

[0029] (3) The powder is crushed, sieved, and then the powder is reduced in a hydrogen atmosphere. The reduction is carried out in two steps. First, it is kept at 500°C for 4 hours, then the temperature is raised to 900°C for 4 hours, and then it is cooled in the furnace. The reduced powder is pressed and sintered into a rare earth-molybdenum secondary electron emission material embryo. The embryo body is machined into a rare ...

Embodiment 3

[0031] (1) Add 32.3318 grams of Y(NO 3 ) 3 , 45.8280 grams of Gd(NO 3) 3 Respectively dissolve in absolute ethanol, filter the solution after it is completely dissolved. Weigh 120.0235 grams of molybdenum trioxide powder and mix with the filtered nitrate solution, and heat it in a water bath at 90°C, stirring continuously until the liquid is completely evaporated.

[0032] (2) The powder obtained after evaporation is decomposed at 550°C in an air atmosphere until the nitrate is completely decomposed, and the N element in the powder is completely removed.

[0033] (3) The powder is crushed, sieved, and then the powder is reduced in a hydrogen atmosphere. The reduction is carried out in two steps. First, it is kept at 550°C for 3 hours, and then the temperature is raised to 900°C for 3 hours, and then cooled in the furnace. The reduced powder is pressed and sintered into a rare earth-molybdenum secondary electron emission material embryo. The embryo body is machined into rare earth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com