Method for improving ferro-nickel alloy plating weldability

A nickel-iron alloy, solderability technology, applied in the field of microelectronic materials, to achieve the effect of simple process, good solderability, and improved oxidation state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

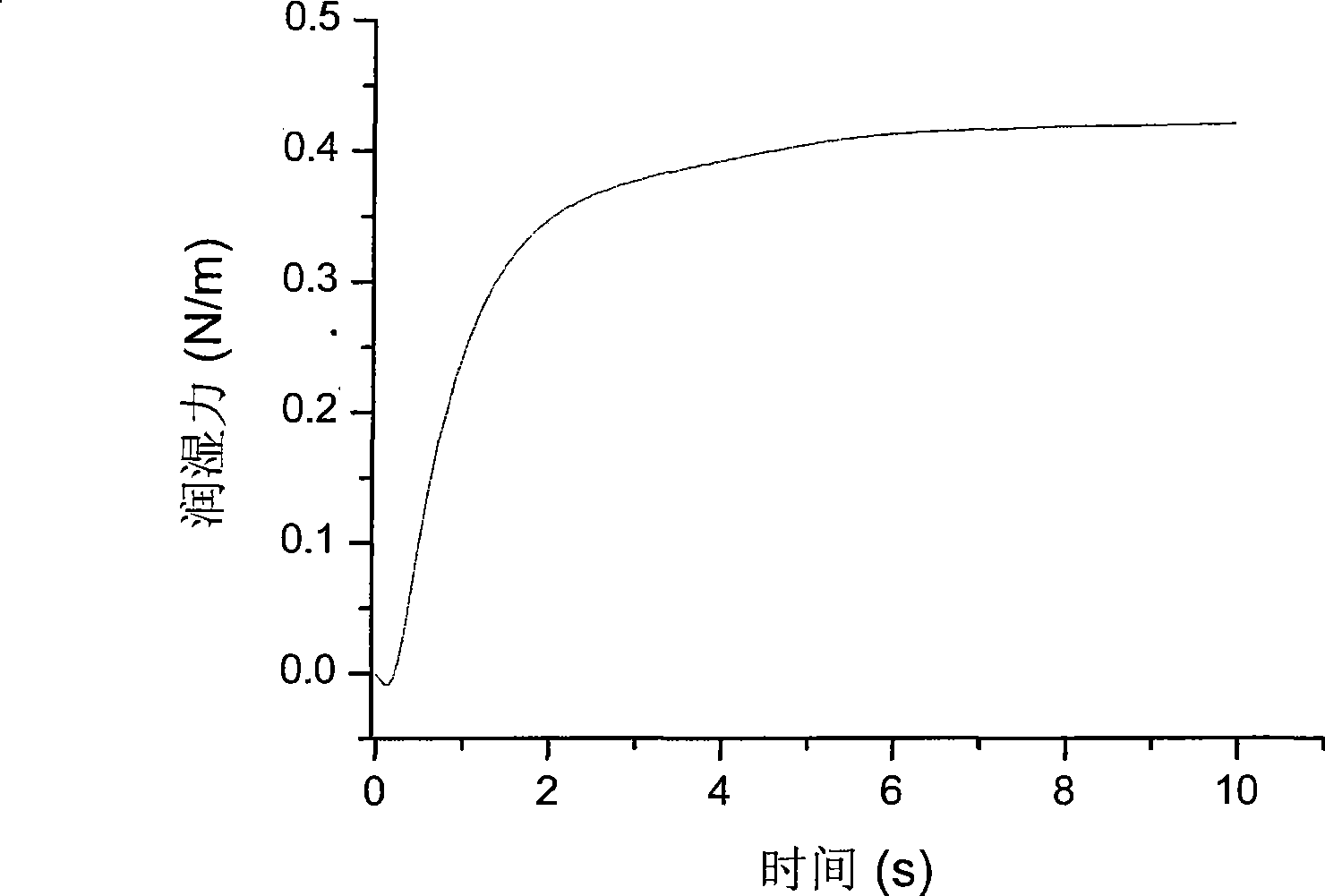

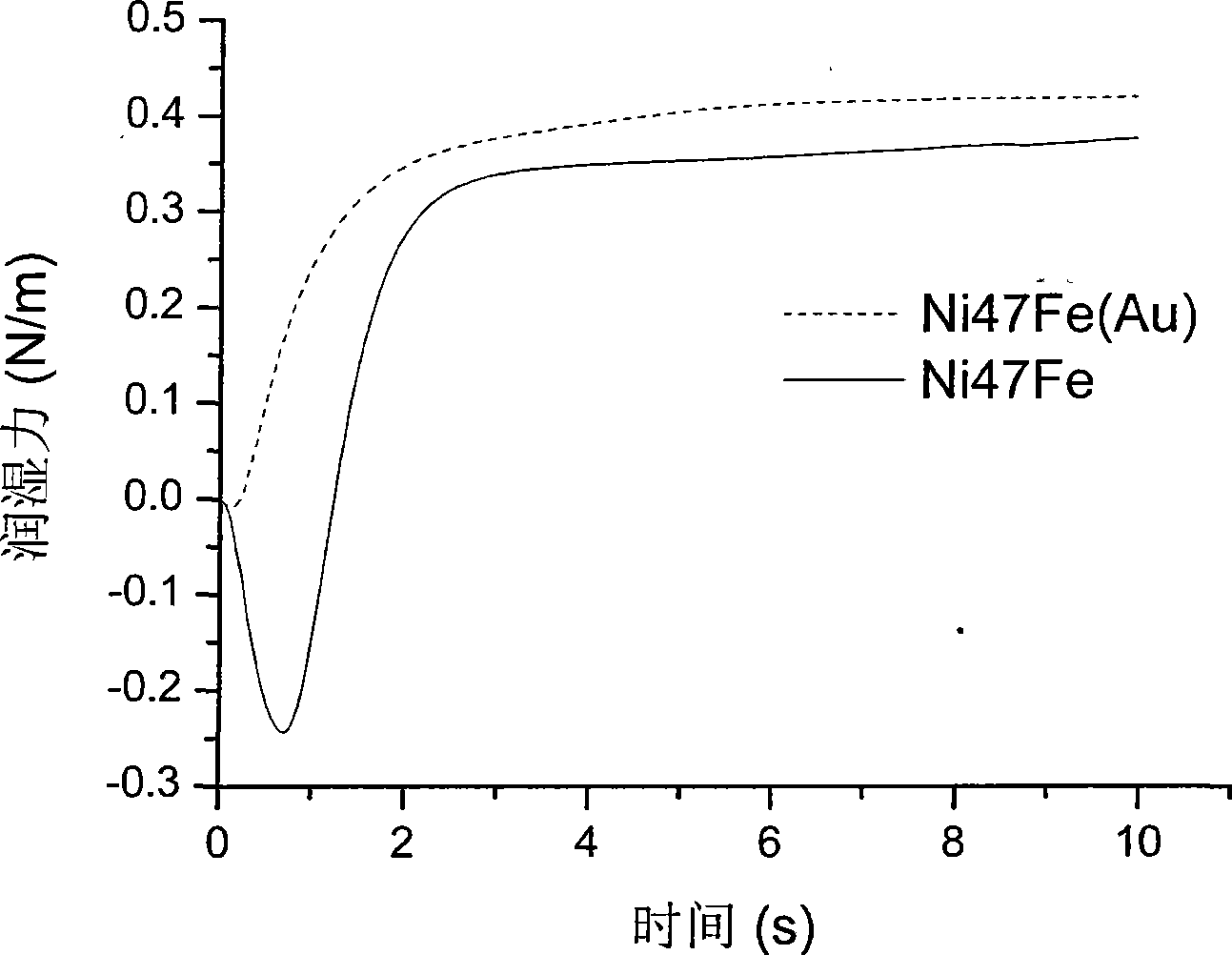

[0028] The electroplating method is used to electroplate a coating composed of Ni-47Fe on a rectangular copper sheet of 20×10 mm. The thickness of the nickel-iron alloy coating in this embodiment is 7 μm. After electroplating, the samples were washed with distilled water and dried. Put into the electroless gold-plating liquid and carry out gold-plating, the gold-plating liquid that chemical gold-plating uses is the cyanide-free gold-plating solution with gold chloride as gold salt. The gold plating temperature was controlled at 50° C. for 10 minutes, and the thickness of the gold protective film obtained in this embodiment was 0.6 um. Using SKC-8H solderability tester for solderability test, the results are as follows figure 1 As shown, from the test results, the sample has good solderability.

Embodiment 2

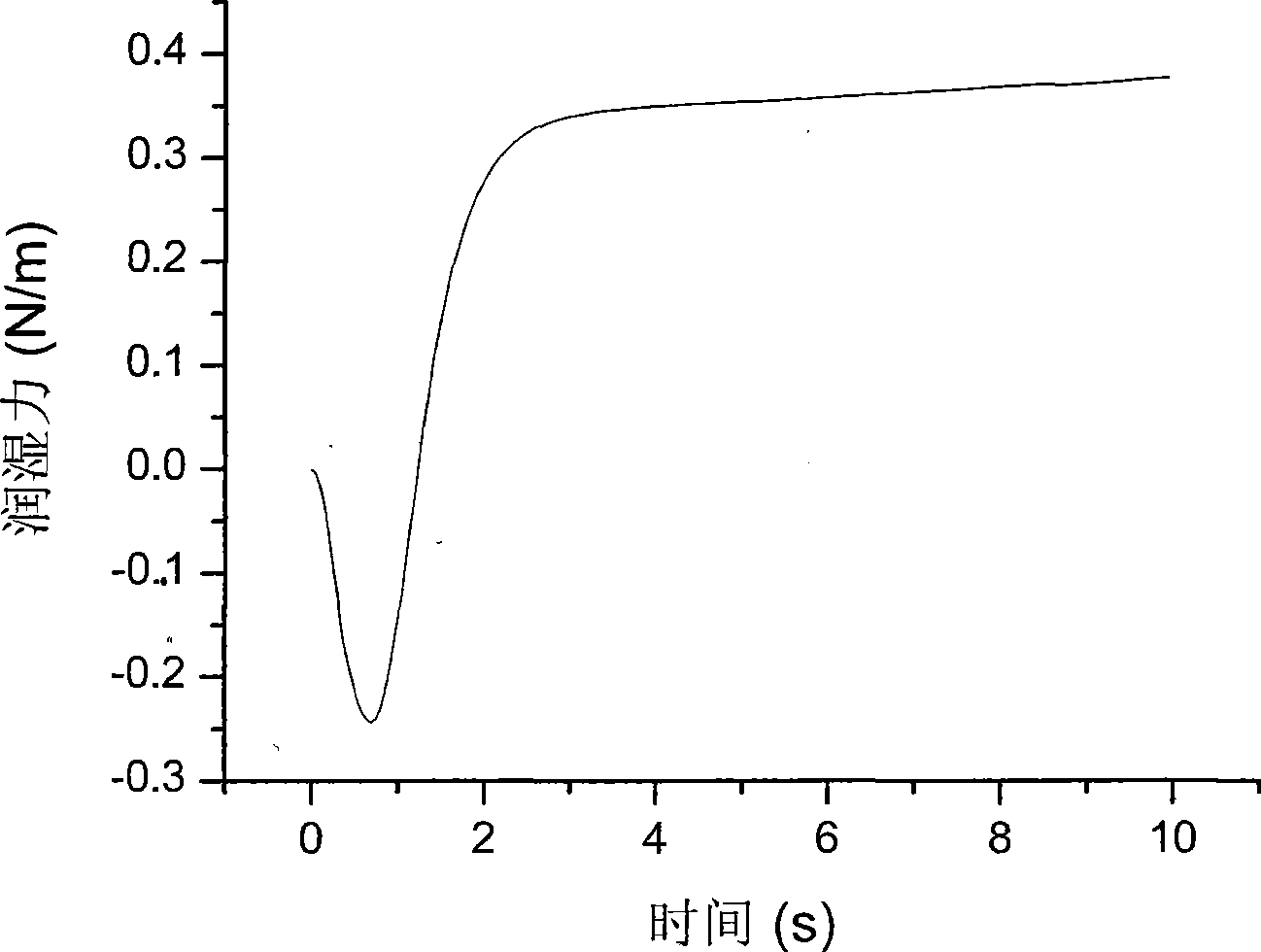

[0034] Using the same electroplating method and electroless plating method, by controlling the ratio of Ni and Fe ions in the electroplating solution, a Ni-71Fe coating with gold plating on the surface is prepared. In this embodiment, the thickness of the nickel-iron alloy coating is 7um, and the thickness of the obtained gold protective film is 0.6um. The solderability of the samples was tested using a solderability tester, and the results were as follows Figure 4 As shown, it can be seen that the solderability of the coating is good.

Embodiment 3

[0040] Use the same electroplating method to electroplate the nickel-iron alloy coating, and plate gold on the coating surface for 5 minutes. In this embodiment, the thickness of the nickel-iron alloy coating is 7um, and the thickness of the obtained gold protective film is 0.45um. The solderability was tested with a solderability tester. The data are shown in Table 3. It can be seen that the solderability of the coating is good, but the wetting time is slightly longer than that of the sample plated with gold for 10 minutes, and the maximum wetting force remains unchanged.

[0041] table 3

[0042] Ni-47Fe Gilded for 5 minutes Gilded for 10 minutes Gilded for 20 minutes Start wetting time (t b ) / s 0.13±0.03 0.11±0.03 0.14±0.03 Maximum wetting force (F max )N / m 0.41±0.01 0.41±0.01 0.41±0.01

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com