Polyethyleneglycol-400 modified TiO2 powder and preparation method

A polyethylene glycol and modification technology, applied in chemical instruments and methods, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high modification cost and low photocatalytic efficiency, and achieve low price and suitable promotion. , the obvious effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

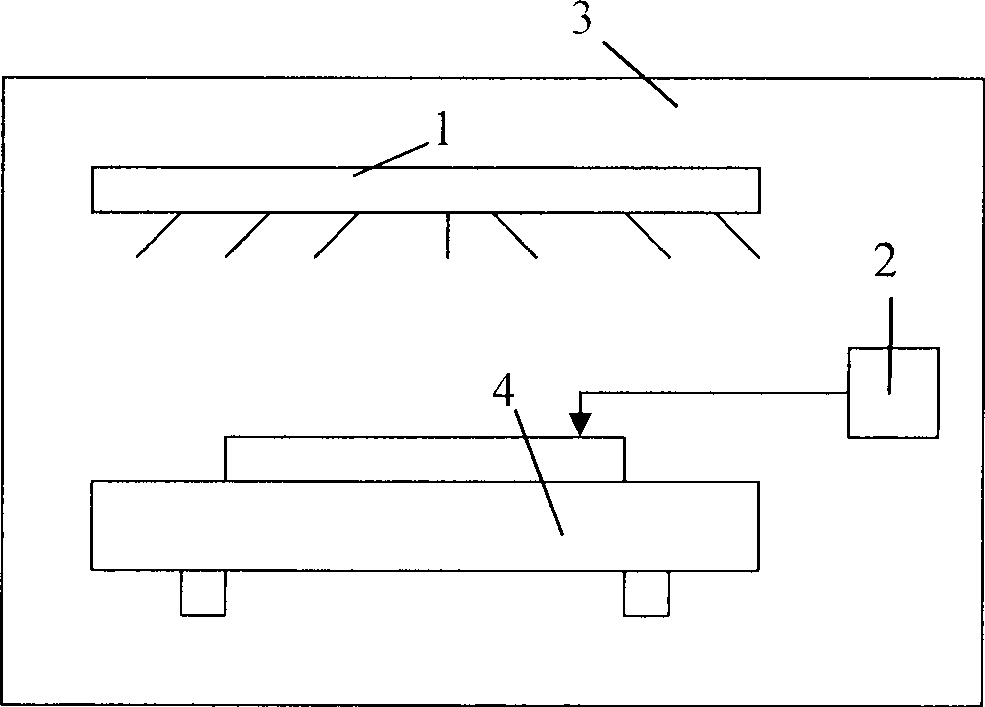

Image

Examples

Embodiment 1

[0030] 1. At room temperature, mix 50mL of absolute ethanol and 6mL of analytically pure concentrated nitric acid to form a mixed solution B, and slowly add the mixed solution B dropwise to the rapidly stirred 34mL butyl titanate solution to make a mixed solution C;

[0031] 2. Take 36mL of absolute ethanol, 6mL of distilled water and 1g of polyethylene glycol-400 at room temperature to make a mixture D;

[0032] 3. Slowly add the mixed solution D to the rapidly stirred mixed solution C. After the dropwise addition, continue to stir to make the mixed solution fully react until the solid components in the mixed solution are evenly dispersed in the solution, then stop stirring. Preparation of Polyethylene Glycol-400 Modified TiO 2 Sol;

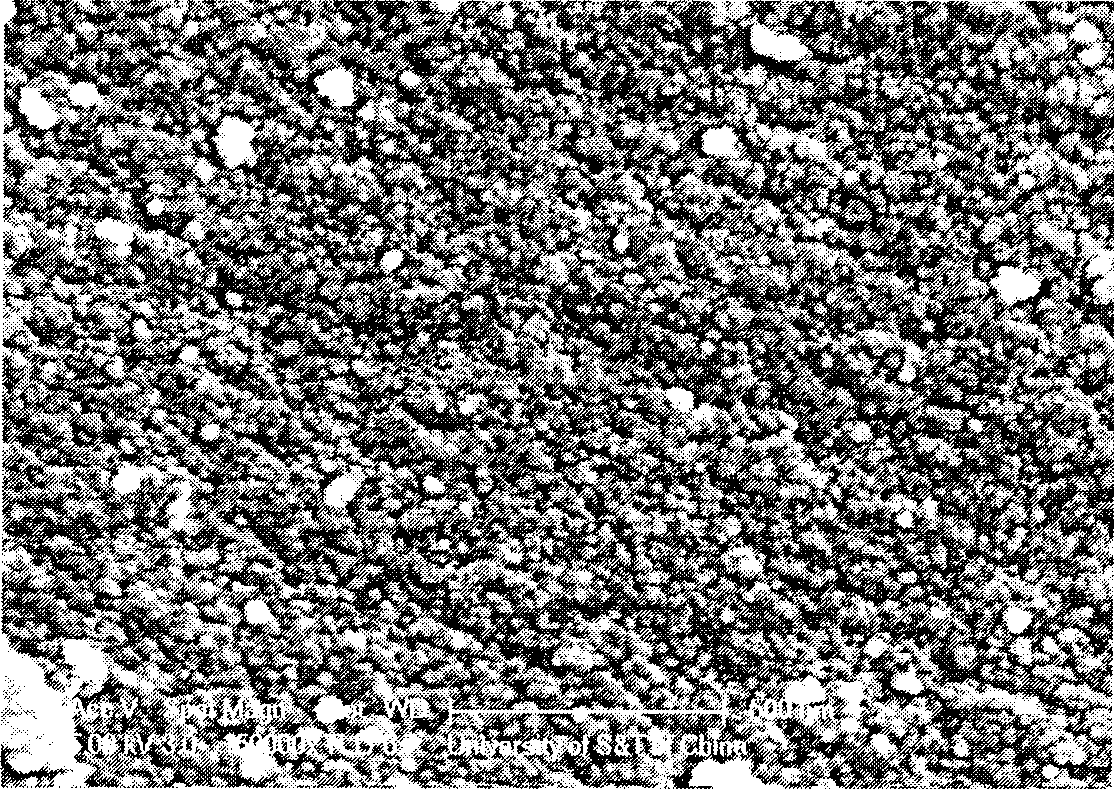

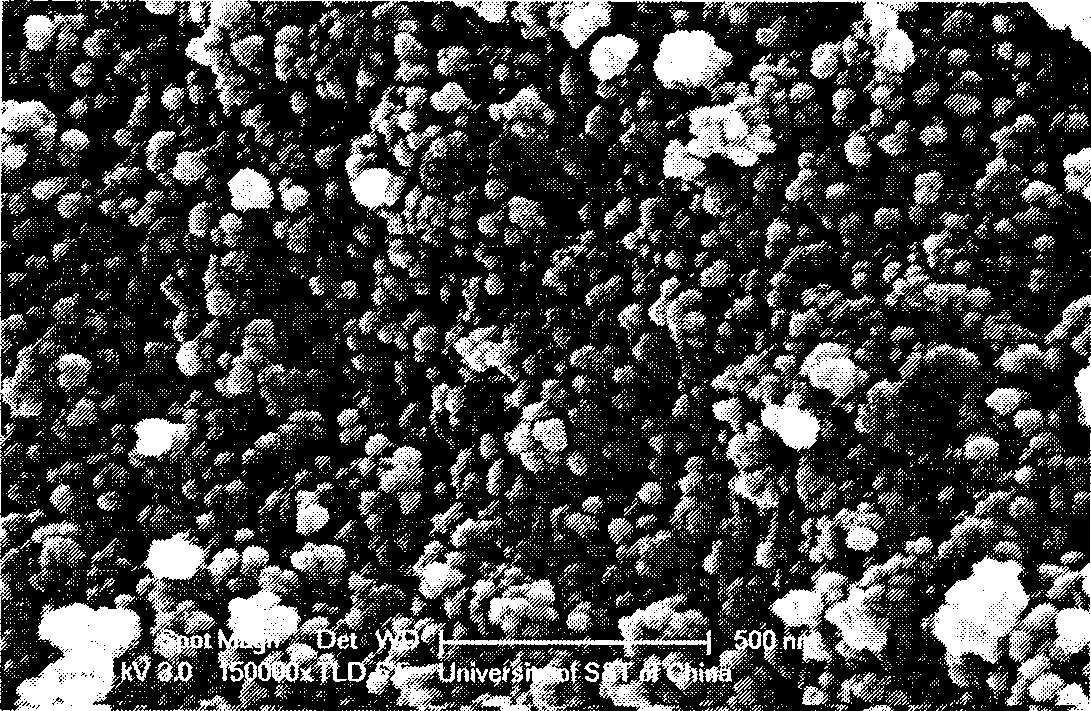

[0033] 4. The polyethylene glycol-400 modified TiO 2 After the sol is aged, it is first dried in a drying oven at 100°C for 1 to 2 hours for gel aging, and then calcined at a constant temperature of 500°C for 1 hour to complete the surface modif...

Embodiment 2

[0035] 1. At room temperature, mix 50mL of absolute ethanol and 6mL of analytically pure concentrated nitric acid to form a mixed solution B, and slowly add the mixed solution B dropwise to the rapidly stirred 34mL butyl titanate solution to make a mixed solution C;

[0036] 2. Take 36mL of absolute ethanol, 6mL of distilled water and 6g of polyethylene glycol-400 at room temperature and mix to make a mixture D;

[0037] 3. Slowly add the mixed solution D to the rapidly stirred mixed solution C. After the dropwise addition, continue to stir to make the mixed solution fully react until the solid components in the mixed solution are evenly dispersed in the solution, then stop stirring. Preparation of Polyethylene Glycol-400 Modified TiO 2 Sol;

[0038] 4. The polyethylene glycol-400 modified TiO 2 After the sol is aged, it is first dried in a drying oven at 100°C for 1 to 2 hours for gel aging, and then calcined at a constant temperature of 500°C for 1 hour to complete the sur...

Embodiment 3

[0040] 1. At room temperature, mix 50mL of absolute ethanol and 6mL of analytically pure concentrated nitric acid to form a mixed solution B, and slowly add the mixed solution B dropwise to the rapidly stirred 34mL butyl titanate solution to make a mixed solution C;

[0041] 2. Take 36mL of absolute ethanol, 6mL of distilled water and 10g of polyethylene glycol-400 at room temperature and mix to make a mixture D;

[0042] 3. Slowly add the mixed solution D to the rapidly stirred mixed solution C. After the dropwise addition, continue to stir to make the mixed solution fully react until the solid components in the mixed solution are evenly dispersed in the solution, then stop stirring. Preparation of Polyethylene Glycol-400 Modified TiO 2 Sol;

[0043] 4. The polyethylene glycol-400 modified TiO 2 After the sol is aged, it is first dried in a drying oven at 100°C for 1 to 2 hours for gel aging, and then calcined at a constant temperature of 500°C for 1 hour to complete the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com