Method for preparing 2-chloro-4-fluorobenzene nitrile

A technology of fluorobenzonitrile and nitrobenzonitrile, which is applied in the field of preparing 2-chloro-4-fluorobenzonitrile, can solve the problems of long synthesis steps, environmental pollution, and low yield, and achieve no pollution, easy-to-obtain raw materials, The effect of high reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

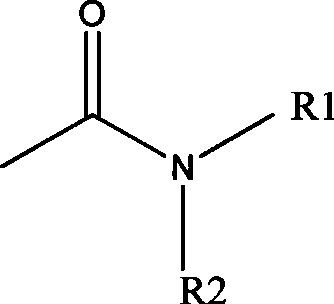

[0022] In a three-necked flask containing 120 g of dimethylacetamide and 58 g of potassium fluoride, add 183 g of 2-chloro-4-nitrobenzonitrile and 2.4 g of catalyst tetraphenyl bromide under stirring, and react at 100-110 °C for 8 ~10h. The solvent dimethylacetamide was distilled off under reduced pressure, the residue was extracted with cyclohexane, and the composition of the extract was analyzed by GC / MS. The extract was rectified under reduced pressure, and 133 g of fractions at 100-120°C / 10Pa were collected and passed through GC. / MS mass spectrometry, m / z: 155.56, proved to be Molecular ion characteristic fragments are measured with a gas chromatograph (GC-2014, purchased from Shimadzu company), the content of 2-chloro-4-fluorobenzonitrile in the fraction is 99.2538%, and the content of 2-chloro-4-fluorobenzonitrile product The yield was 85.26%.

Embodiment 2

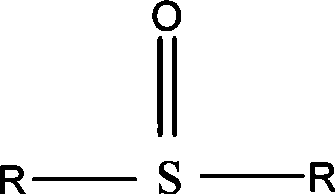

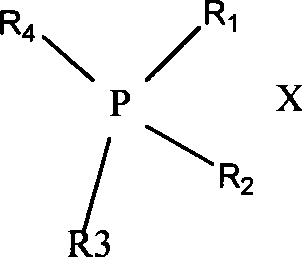

[0024] In a three-necked flask containing 714g of dimethyl sulfoxide and 174g of potassium fluoride, add 183g of 2-chloro-4-nitrobenzonitrile and 18g of catalyst tetraethylphosphorous chloride under stirring, and react at 130-150°C for 5 ~8h. The solvent dimethyl sulfoxide was distilled off under reduced pressure, the residue was extracted with cyclohexane, and the composition of the extract was analyzed by GC / MS. The extract was rectified under reduced pressure, and 126 g of fractions at 100-120°C / 10Pa were collected and passed through GC. / MS mass spectrometry, m / z: 155.56, proved to be Molecular ion characteristic fragments are measured with a gas chromatograph (GC-2014, purchased from Shimadzu company), and the content of 2-chloro-4-fluorobenzonitrile in the fraction is 99.3687%, and the content of 2-chloro-4-fluorobenzonitrile product is The yield was 80.77%.

Embodiment 3

[0026] In a three-neck flask filled with 500g of dibutylacetamide and 87g of potassium fluoride, add 330g of 2-chloro-4-nitrobenzonitrile and 4g of catalyst tetraphenylbromophosphorus under stirring, and react at 130°C for 5 to 8 hours . The solvent dibutylacetamide was distilled off under reduced pressure, the residue was extracted with cyclohexane, and the composition of the extract was analyzed by GC / MS. The extract was rectified under reduced pressure, and 228 g of fractions at 100-120°C / 10Pa were collected and passed through GC. / MS mass spectrometry, m / z: 155.56, proved to be Molecular ion characteristic fragments are measured with a gas chromatograph (GC-2014, purchased from Shimadzu company), and the content of 2-chloro-4-fluorobenzonitrile in the fraction is 99.0327%, and the content of 2-chloro-4-fluorobenzonitrile product The yield was 81.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com