Cable and production method for solar energy photovoltaic power generation system

A solar photovoltaic and power generation system technology, which is applied in the direction of cable/conductor manufacturing, insulating cables, conductor/cable insulation, etc., can solve the problems of mechanical performance degradation, solar photovoltaic power generation system paralysis, solar photovoltaic power generation system leakage and injury, etc. Achieve excellent mechanical properties, improve service life and ability to resist harsh weather environments, and enhance the effect of UV protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

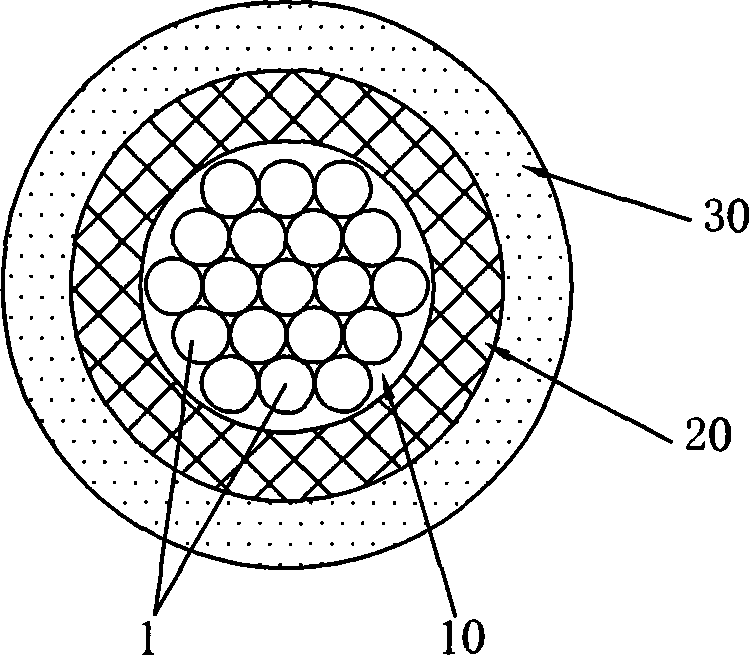

[0018] Polyethylene is a high-quality chemical raw material. Through the cross-linking reaction, the polyethylene molecule changes from a two-dimensional structure to a three-dimensional network structure. The chemical and physical properties of the material are correspondingly enhanced, and the temperature and pressure resistance performance is improved. The material is cross-linked polyethylene. The cross-linking methods of polyethylene include physical cross-linking, that is, radiation cross-linking and chemical cross-linking. The electron accelerator treatment adopted in the present invention is a physical cross-linking method.

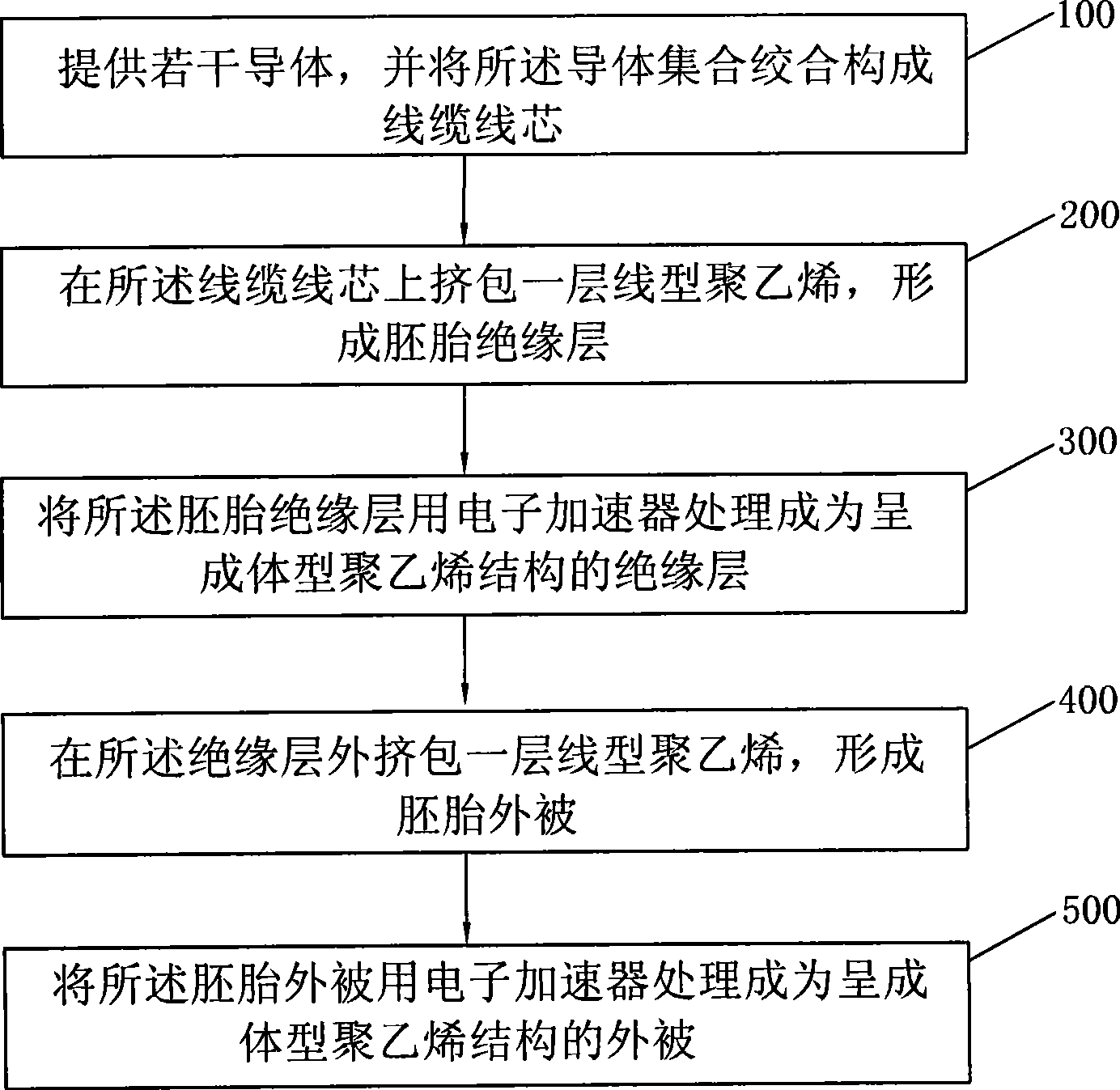

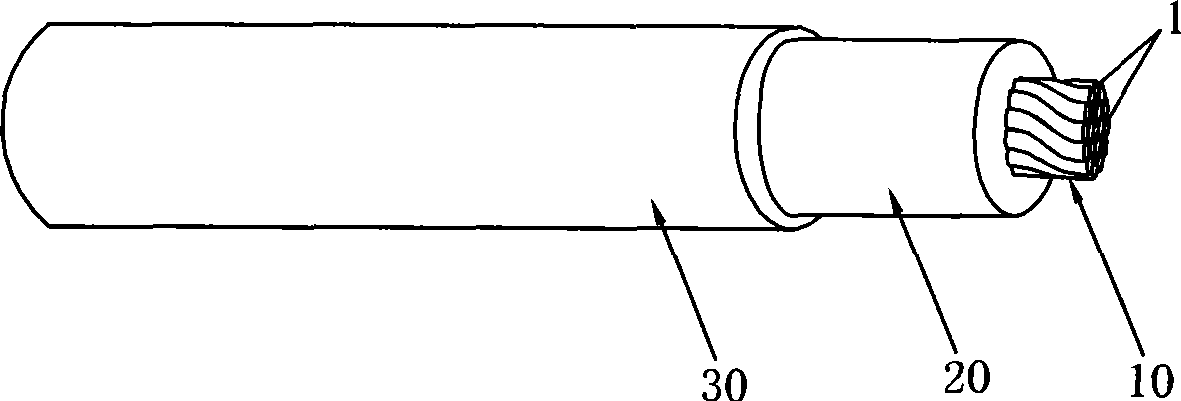

[0019] Such as figure 1 As shown, the method for manufacturing a cable for a solar photovoltaic power generation system of the present invention includes the following steps: (100) providing several conductors, and twisting the conductors together to form a cable core, specifically, the conductors are tinned copper wires , the lay distance of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com