Preparation of graphene

A technology of graphene and halogenated hydrocarbons, which is applied in the field of chemical synthesis, can solve the problems of large graphene structure damage, complicated steps, and low efficiency, and achieve the effects of low raw material cost, simple equipment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

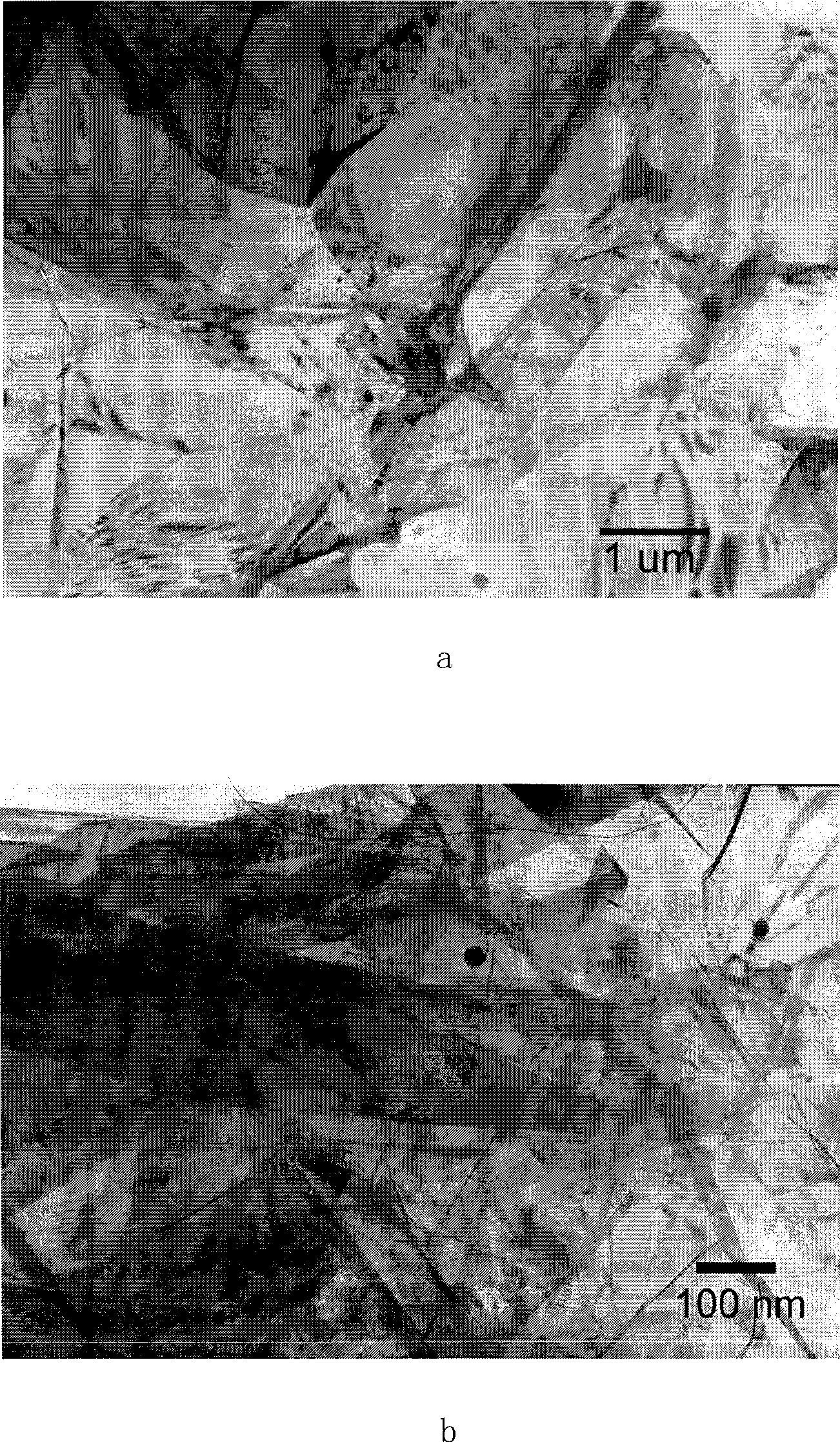

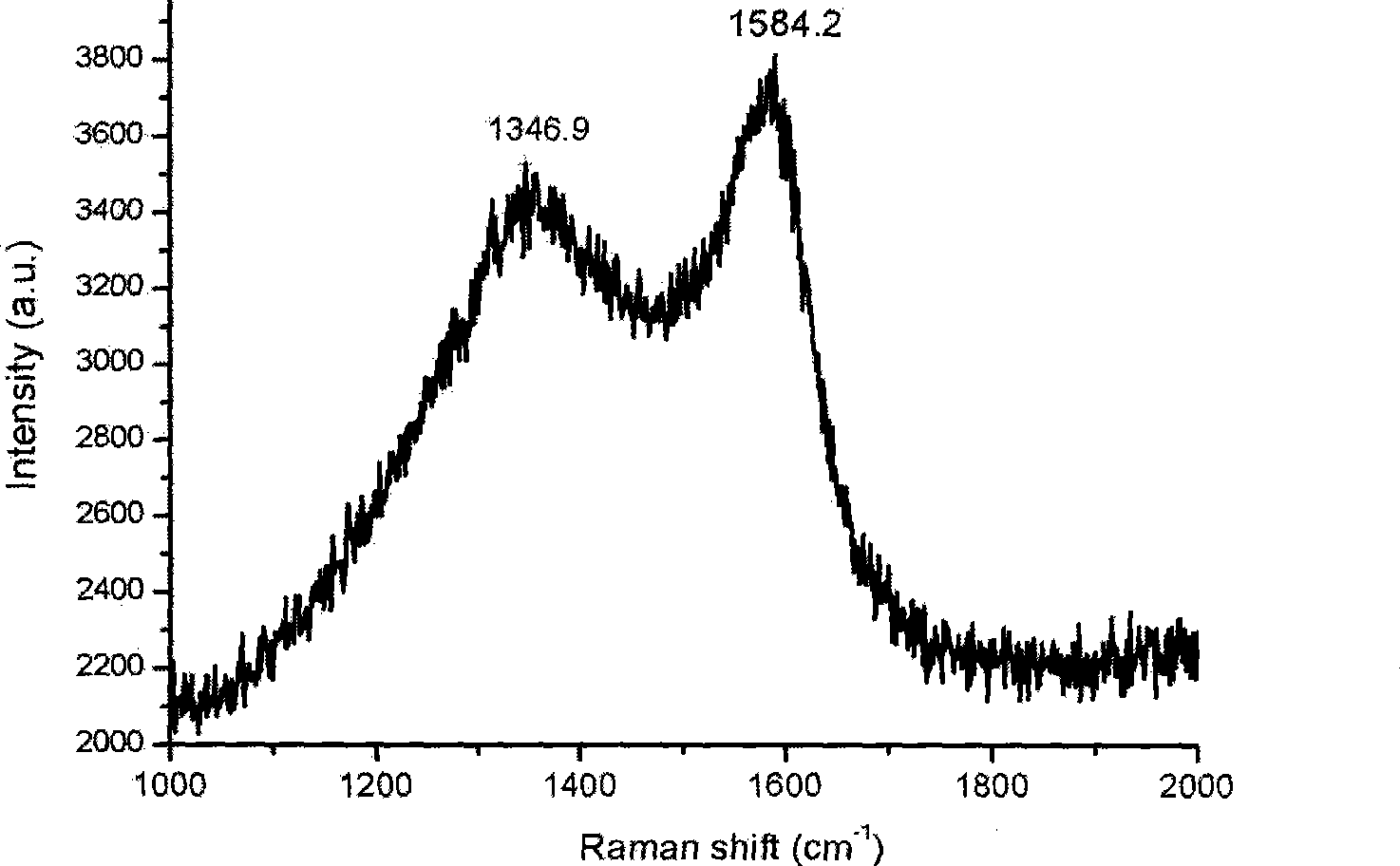

Image

Examples

Embodiment 1

[0041] Embodiment 1 - the preparation of graphene

[0042] The device used in the preparation of graphene in this embodiment includes: three-necked grinding bottle (250mL, reaction kettle), spherical condenser, electric heating mantle, high-purity nitrogen cylinder (providing nitrogen), capillary glass tube, thermometer sleeve, rubber tube and thermometer (0-400°C).

[0043]The specific method of the method that present embodiment prepares graphene comprises the following steps:

[0044] 1. Synthesis of graphene

[0045] First dry the three-necked bottle with ground mouth in an oven, add 50mL of paraffin oil to it, wipe off the impurities on the surface of the sodium metal, then place it on a watch glass and weigh 2.0g of sodium with a balance, put it directly into the three-necked bottle, add 1.0mL tetrachlorethylene, stir evenly; then connect the thermometer with the thermowell, and plug it into a bottle mouth on the side of the three-necked bottle. One end of the tube is...

Embodiment 2

[0053] Embodiment 2 - the preparation of graphene

[0054] Graphene is prepared with the experimental device identical with embodiment 1, and concrete preparation method comprises the following steps:

[0055] 1. Synthesis of graphene

[0056] Add 50mL of diphenyl ether into the dried ground three-neck bottle, wipe off the impurities on the surface of metallic sodium, then place it on a watch glass and weigh 2.3g (0.1 mole) of sodium with a balance, and put it directly into the three-necked bottle , add tetrachlorethylene 0.016g (0.001 mole), stir evenly; 2 5min, then, switch on the cooling water of the spherical condenser connected to the there-necked flask, start heating the there-necked flask with an electric heating mantle, and at the same time stir the system at a slow speed so that the sodium can be stirred as a whole, and heat to 160°C (the temperature is regulated by controlling the power of the electric heating mantle), and the reaction is stopped after maintaining...

Embodiment 3

[0060] Embodiment 3 - the preparation of graphene

[0061] The device used in the preparation of graphene in this embodiment includes: three-necked grinding bottle (250mL, reaction kettle), spherical condenser, electric heating mantle, high-purity nitrogen cylinder (providing nitrogen), capillary glass tube, thermometer sleeve, rubber tube And thermometer (0-400°C), bubbling device. Concrete preparation method comprises the following steps:

[0062] 1. Synthesis of graphene

[0063] First add 50mL of paraffin oil to the three-neck bottle with ground mouth dried in an oven, wipe off the impurities on the surface of the metallic sodium, then place it on a watch glass and weigh 2.0g of sodium with a balance, and put it directly into the three-necked bottle. Add 2ml of tetrachlorethylene into the bubbling device, open the pressure reducing valve of the nitrogen bottle, and blow nitrogen gas at a speed of about 100 bubbles per minute, then connect the cooling water of the spheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com