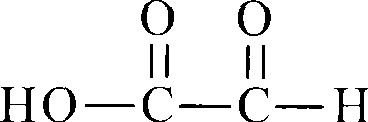

Method for preparing ethanol acid by catalytic oxidation of biformyl

A technology of glyoxal catalysis and glyoxylic acid, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve problems such as unsatisfactory yield of glyoxylic acid and low conversion rate of glyoxylic acid , to achieve the effect of stable quality, improved conversion rate and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Prepare the catalyst: Add 10g of ammonium metavanadate, 5g of ammonium dichromate, 2.5g of ammonium niobium oxalate and 20g of water into a reactor with stirring and a thermometer, dissolve under stirring, add 20g of 20-100 mesh (0.0009- 0.00018m) coarse-porous microsphere silica gel, maintained at 20-30°C for 24 hours, filtered the obtained catalyst precursor and dried at 80°C for 4 hours, then placed in a tube furnace, introduced nitrogen, and maintained at a temperature of 250±10°C for activation After 3 hours, 35 g of activated catalysts were prepared and cooled to room temperature for use;

[0023] 2. In the autoclave with heating, stirring and thermometer, add 40wt% glyoxal 95.5g (0.66mol) respectively, step (1) catalyst 1g, import oxygen, control reaction pressure 0.15MPa, temperature 55 ± 5 ℃, reacted for 6 hours, filtered the obtained reaction product at room temperature, and left the mother liquor after removing the catalyst overnight;

[0024] 3. Filter t...

Embodiment 2

[0026] 1. Prepare the catalyst: Add 10g of ammonium metavanadate, 2g of ammonium dichromate, 1g of ammonium niobium oxalate and 25g of water into a reactor with stirring and a thermometer, dissolve under stirring, add 20g of 20-100 mesh (0.0009-0.00018 m) Coarse-porous microsphere silica gel, maintained at 20-30°C for 24 hours, filtered the obtained catalyst precursor and dried at 90°C for 2.5 hours, then placed in a tube furnace, introduced nitrogen, and maintained at a temperature of 280±10°C for activation 2 Hours, 30 g of activated catalysts were prepared and cooled to room temperature for use.

[0027] 2. In the autoclave with heating, stirring and thermometer, add 50wt% glyoxal 152.5g (1.31mol) respectively, step (1) catalyst 2g, import oxygen, control reaction pressure 0.13MPa, temperature 60 ± 5 ℃, reacted for 4 hours, filtered the obtained reaction product at room temperature, and left the mother liquor after removing the catalyst overnight;

[0028] 3. Filter the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com