Thin-film deposition apparatus using discharge electrode and solar cell fabrication method

A discharge electrode and electrode technology, applied in the direction of discharge tube, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effects of suppressing film thickness distribution or film quality distribution, improving film quality distribution, and increasing film production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

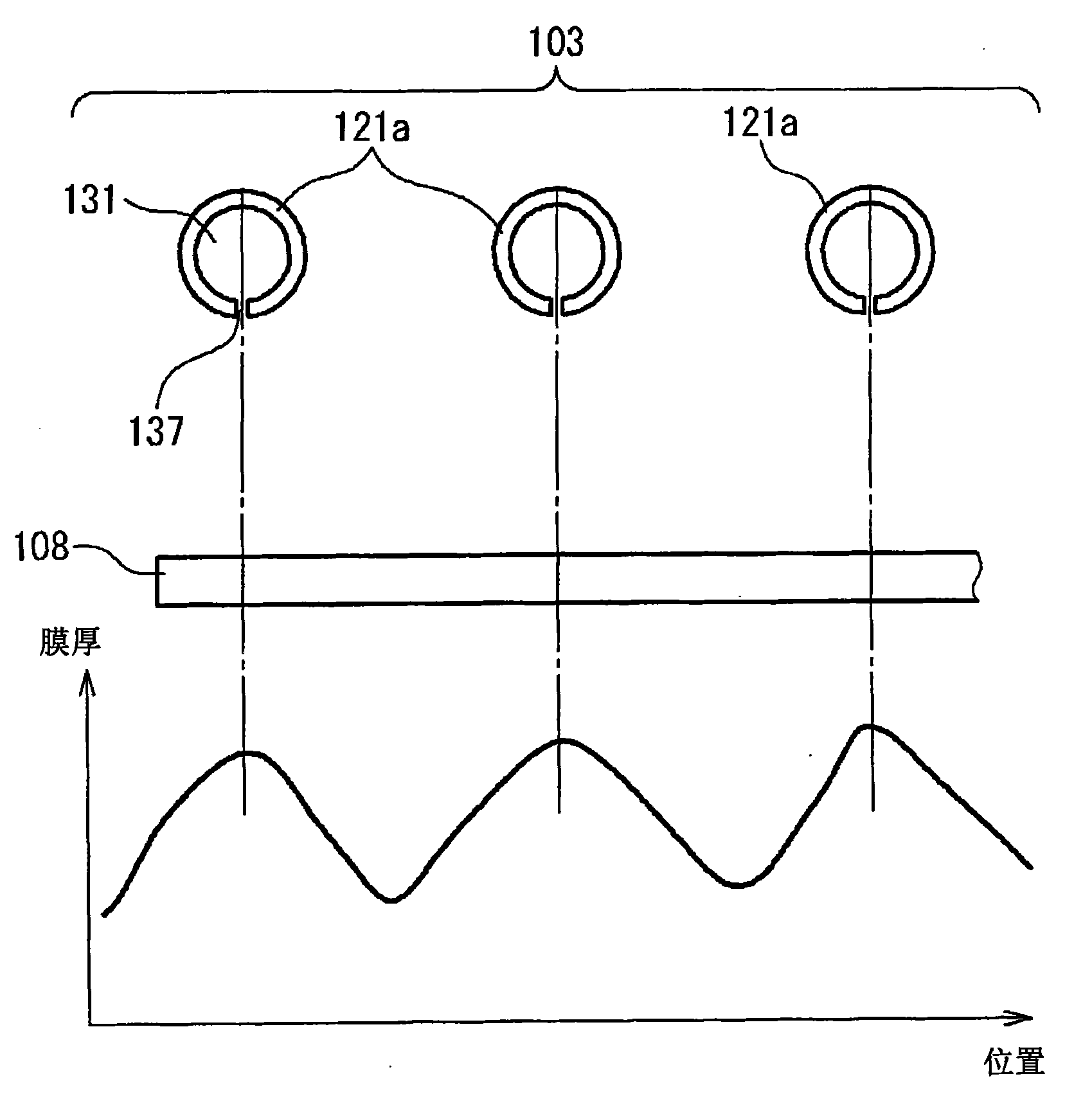

[0052] First, the configuration of the thin film manufacturing apparatus according to the first embodiment of the present invention will be described. Figure 4 It is a side sectional view showing a schematic configuration of a thin film manufacturing apparatus according to a first embodiment of the present invention. The thin film manufacturing device 1 is equipped with: a film forming chamber 6, a counter electrode 2, a vapor chamber 5, a vapor chamber holding mechanism 11, a discharge electrode 3, a protective plate 4, a support portion 7, and a high-frequency power supply transmission path 12 (12a, 12b ), coupler 13 (13a, 13b), high vacuum exhaust section 19, low vacuum exhaust section 17, and stage 18. The configuration related to gas supply is omitted in this figure.

[0053] The film forming chamber 6 is a vacuum container, and a film is formed on the substrate 8 inside. The film production chamber 6 is held on a table 18 .

[0054] The counter electrode 2 is a metal...

no. 2 Embodiment

[0139] Next, the configuration of a thin film manufacturing apparatus according to a second embodiment of the present invention will be described. In this embodiment, the structure of the discharge electrode 3 is different from that of the first embodiment.

[0140] Concerning the configuration of the thin film manufacturing apparatus of the second embodiment of the present invention, the configuration related to the supply of high-frequency power in the thin film manufacturing apparatus of the second embodiment of the present invention, and Figure 4 ~ Figure 6 The structure of the first embodiment shown is the same. Therefore, its description is omitted.

[0141] Figure 16 A cross-section ( Figure 5 BB profile). XYZ directions and Figure 5 The situation is the same. The vertical structure 21 (21a') in the second embodiment is based on the vertical structure 21 (21a) in the first embodiment, and the electrode main body 35 can be divided into the +Z side part, that is...

no. 3 Embodiment

[0146] Next, the configuration of a thin film manufacturing apparatus according to a third embodiment of the present invention will be described. In this embodiment, the structure of the discharge electrode 3 is different from that of the first and second embodiments.

[0147] Concerning the configuration of the thin film manufacturing apparatus of the third embodiment of the present invention, the configuration related to the supply of high-frequency power in the thin film manufacturing apparatus of the third embodiment of the present invention, and Figure 4 ~ Figure 6 The structure of the first embodiment shown is the same. Therefore, its description is omitted.

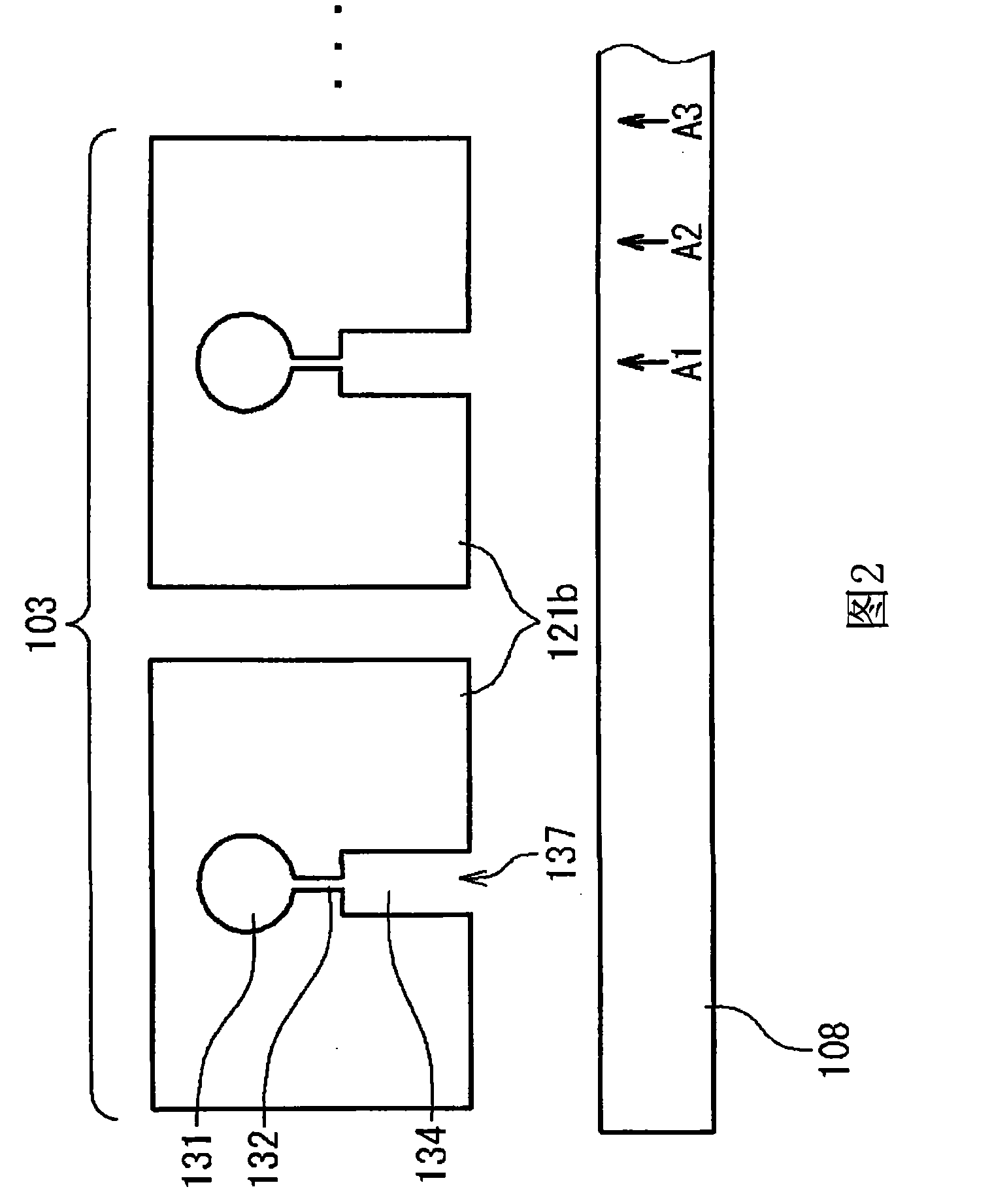

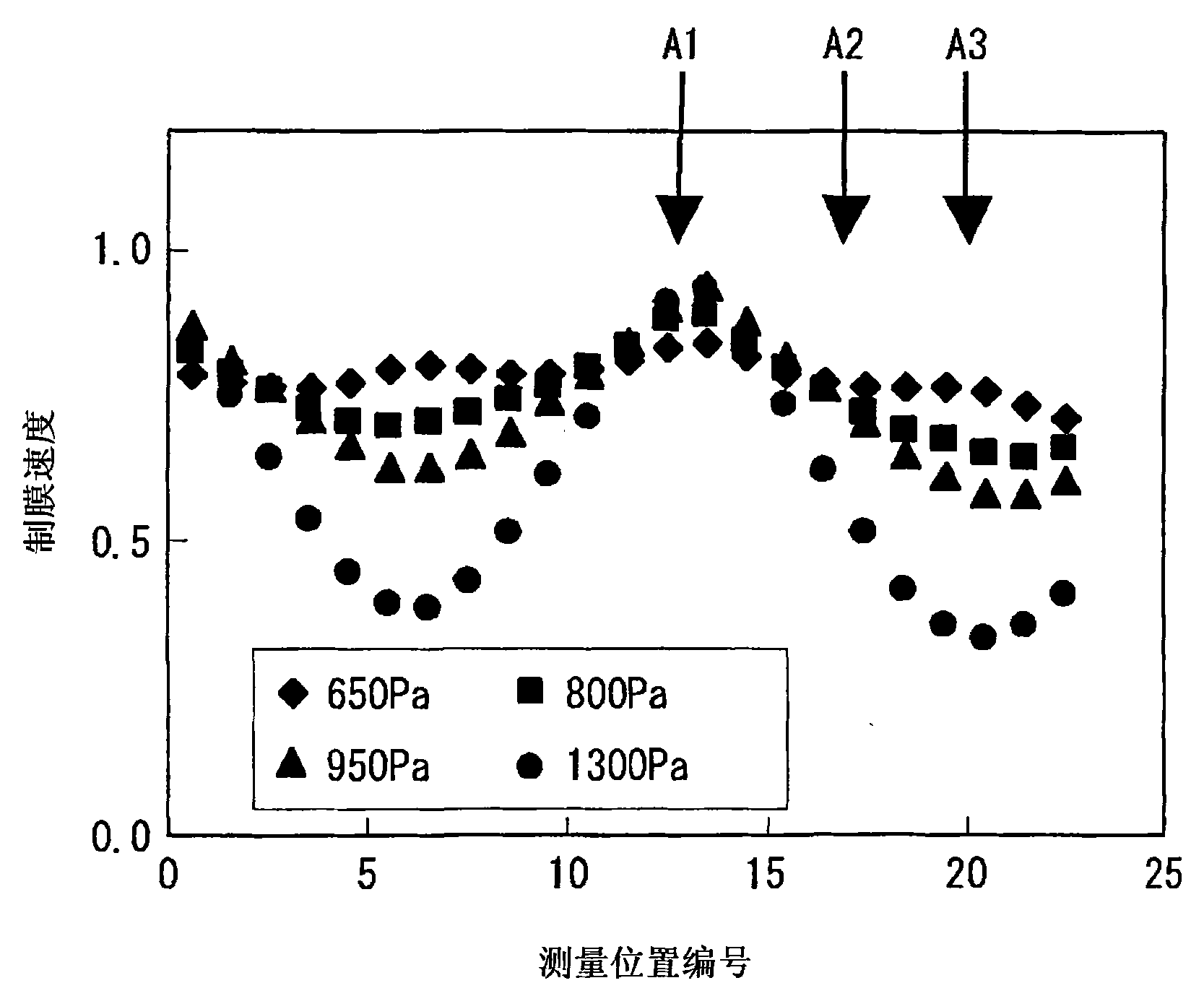

[0148] Figure 17 A cross-section ( Figure 5 BB profile). XYZ directions and Figure 5 The situation is the same. The plurality of vertical structures 21 (21b) of the discharge electrode 3a in the third embodiment each include an electrode main body 71 as a +Z side portion, a gas block 76 as a -Z side porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com