Preparation device and preparation method for widened self-supported silicon-oxygen-carbon thin film

A technology of silicon oxygen carbon thin film and preparation device, which is applied in the field of widened self-supporting silicon oxygen carbon thin film preparation device and preparation, to achieve the effect of simple operation, simple process and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

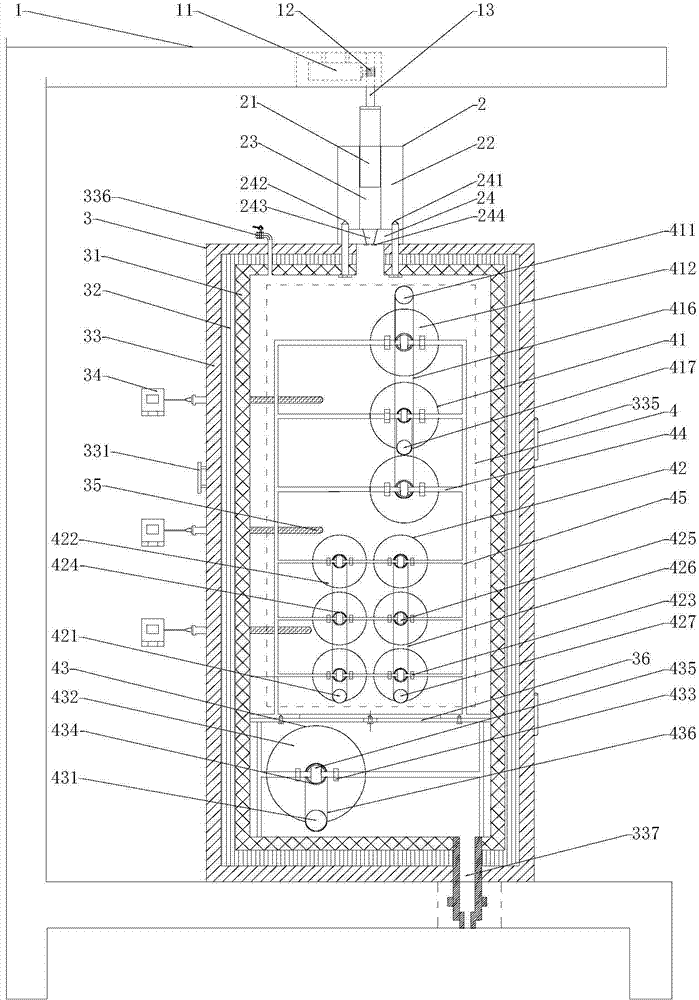

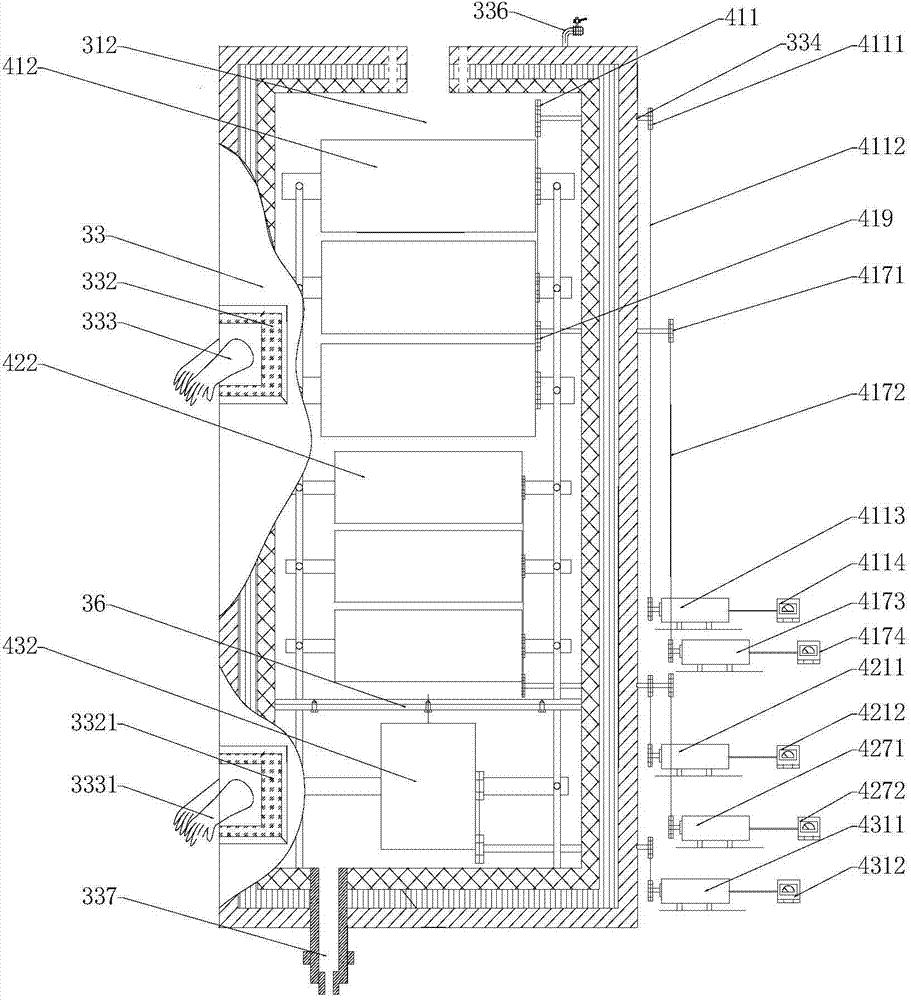

[0033] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] 1) Take 10g of PCS precursor, fix the size of the film spray port by adjusting the left and right splints under the film spray port, and then perform degassing treatment on PCS: the degassing device used should preferably be the structure described in Chinese patent ZL 2008100705331: Put the solid polycarbosilane into the barrel of the defoaming device, install the ejector rod 21, the upper sealing cover (not shown in the figure, refer to the patent ZL2008100705331, the same below), the gasket and the lower sealing cover, and use four screws lock tight. After assembly, put the defoaming device filled with solid polycarbosilane into the vacuum furnace, set the temperature rise program as the temperature rises from room temperature to 260°C in 100 minutes, then rises to 290-300°C in 20 minutes, and then keep warm at this te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com