A kind of heterojunction, its preparation method and application

A heterojunction, antimony sulfide technology, applied in final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as low photoelectric conversion efficiency of solar cells, improve transmission and collection efficiency, and facilitate the process. Feasible, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

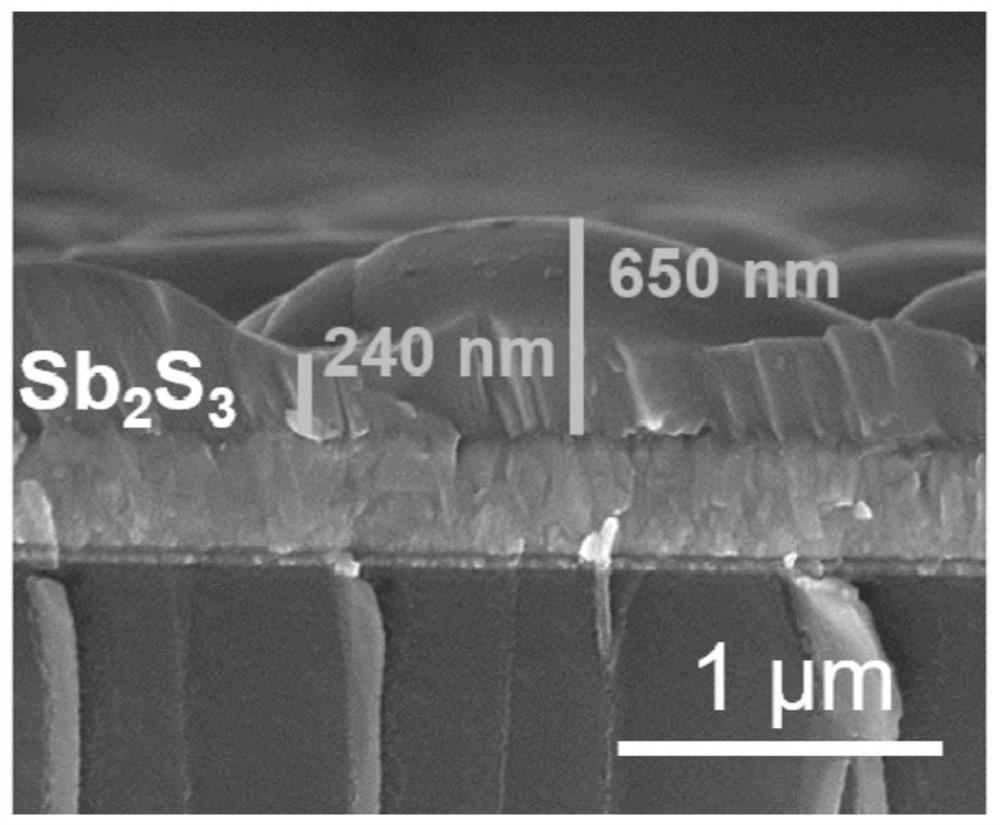

[0051] The present invention also provides the preparation method of the heterojunction, which exposes the substrate material to a crystal plane that matches the [hk1] orientation crystal plane of antimony sulfide, wherein h and k are integers, and 1 is the number 1 . At the same time, the substrate material also exposes atomic vacancies, which are oxygen vacancies or sulfur vacancies; the exposed oxygen vacancies or sulfur vacancies of the substrate material assist in inducing the epitaxial growth of antimony sulfide on the substrate surface.

[0052] In some embodiments, the substrate is annealed to cause a crystal phase transition to expose a crystal plane matching the [hk1] orientation crystal plane of the antimony sulfide, thereby inducing the epitaxial growth of the antimony sulfide on the substrate surface.

[0053] In some embodiments, the substrate is subjected to high-temperature annealing treatment to cause a crystal phase transition, from the traditional disordered...

Embodiment 1

[0074] A method for preparing a heterojunction comprising an antimony sulfide film epitaxially grown in [hk1] orientation, comprising the following steps:

[0075] (1) Substrate TiO 2 Preparation of: diisopropyl di(acetylacetonate) titanate (C 16 h 28 o 6 Ti) was mixed with absolute ethanol at a volume ratio of 1:9, and stirred for 24 hours to serve as a precursor solution. Wash the glass or conductive glass and spray the precursor solution at 450°C, where nitrogen is used as the carrier gas during the spraying process, and then kept at this temperature for 30 minutes and then cooled;

[0076] (2) Substrate TiO 2 Post-processing: the TiO described in step (1) 2 The sample is placed on a hot stage and annealed in air for 30-60 minutes at a temperature of 500°C.

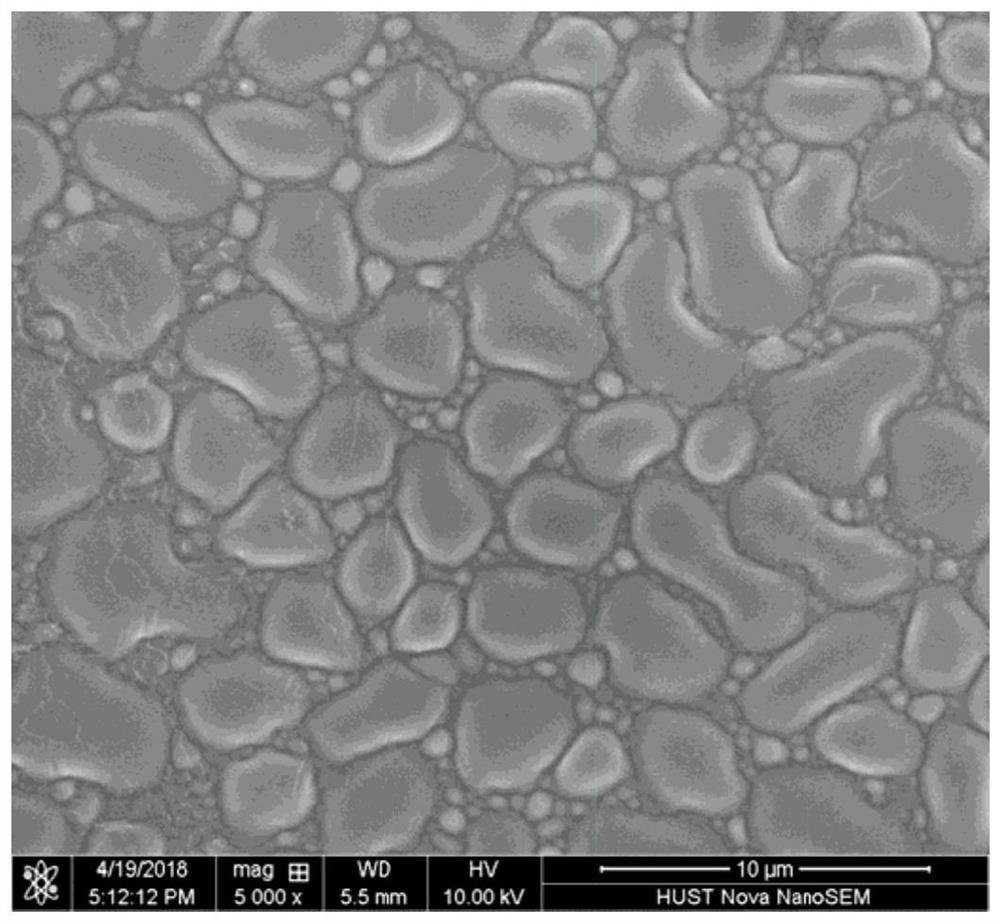

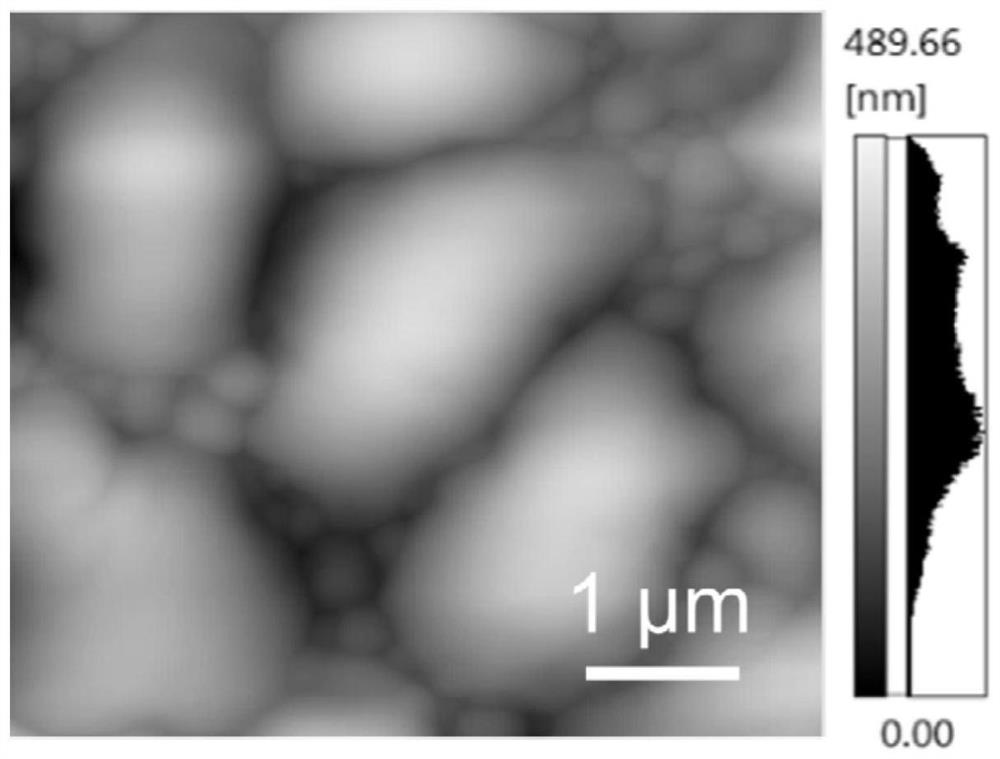

[0077] (3) Preparation of antimony sulfide film: Weigh 0.42g of antimony sulfide powder, sieve it three times with a 50-mesh sieve, so that the antimony sulfide powder can be evenly dispersed, and then sprinkle t...

Embodiment 2

[0083] A method for preparing a heterojunction comprising an antimony sulfide film epitaxially grown in [hk1] orientation, comprising the following steps:

[0084] (1) Substrate TiO 2 Preparation of: diisopropyl di(acetylacetonate) titanate (C 16 h 28 o 6Ti) was mixed with absolute ethanol at a volume ratio of 1:9, and stirred for 24 hours to serve as a precursor solution. Wash the glass or conductive glass and spray the precursor solution at 450°C, where nitrogen is used as the carrier gas during the spraying process, and then kept at this temperature for 30 minutes and then cooled;

[0085] (2) Substrate TiO 2 Post-processing: the TiO described in step (1) 2 The sample is placed on a hot stage and annealed in air for 30-60 minutes at a temperature of 500°C.

[0086] (3) Preparation of antimony sulfide film: Weigh 0.42g of antimony sulfide powder, sieve it three times with a 50-mesh sieve, so that the antimony sulfide powder can be evenly dispersed, and then sprinkle th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com