Double solvent for extracting, distilling and separating styrene in hydrocarbons mixture

A hydrocarbon mixture and composite solvent technology, applied in distillation purification/separation, organic chemistry, etc., can solve the problems of low industrial practical value and high cost, and achieve the effect of reducing polymerization and comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

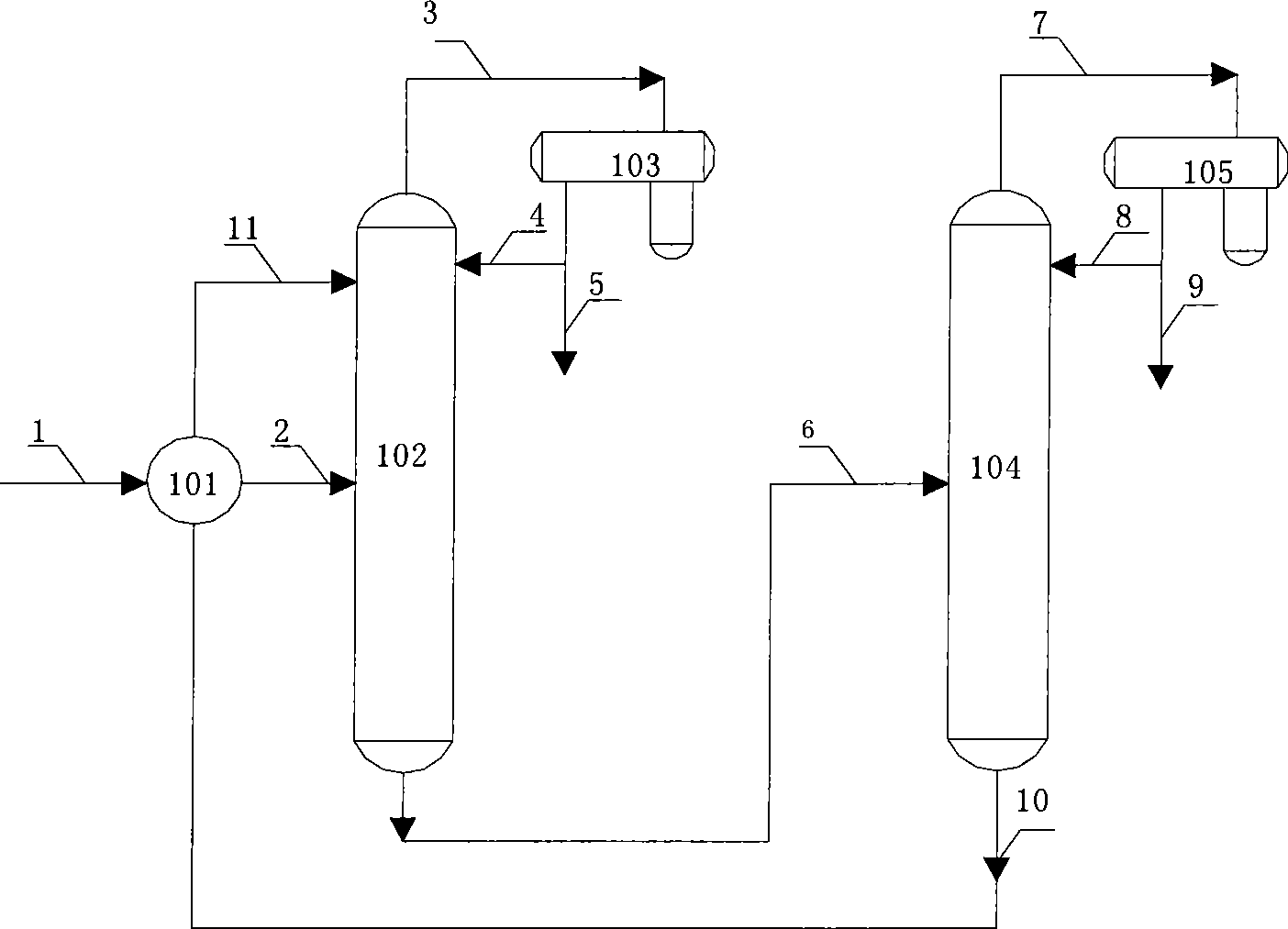

Method used

Image

Examples

example 1

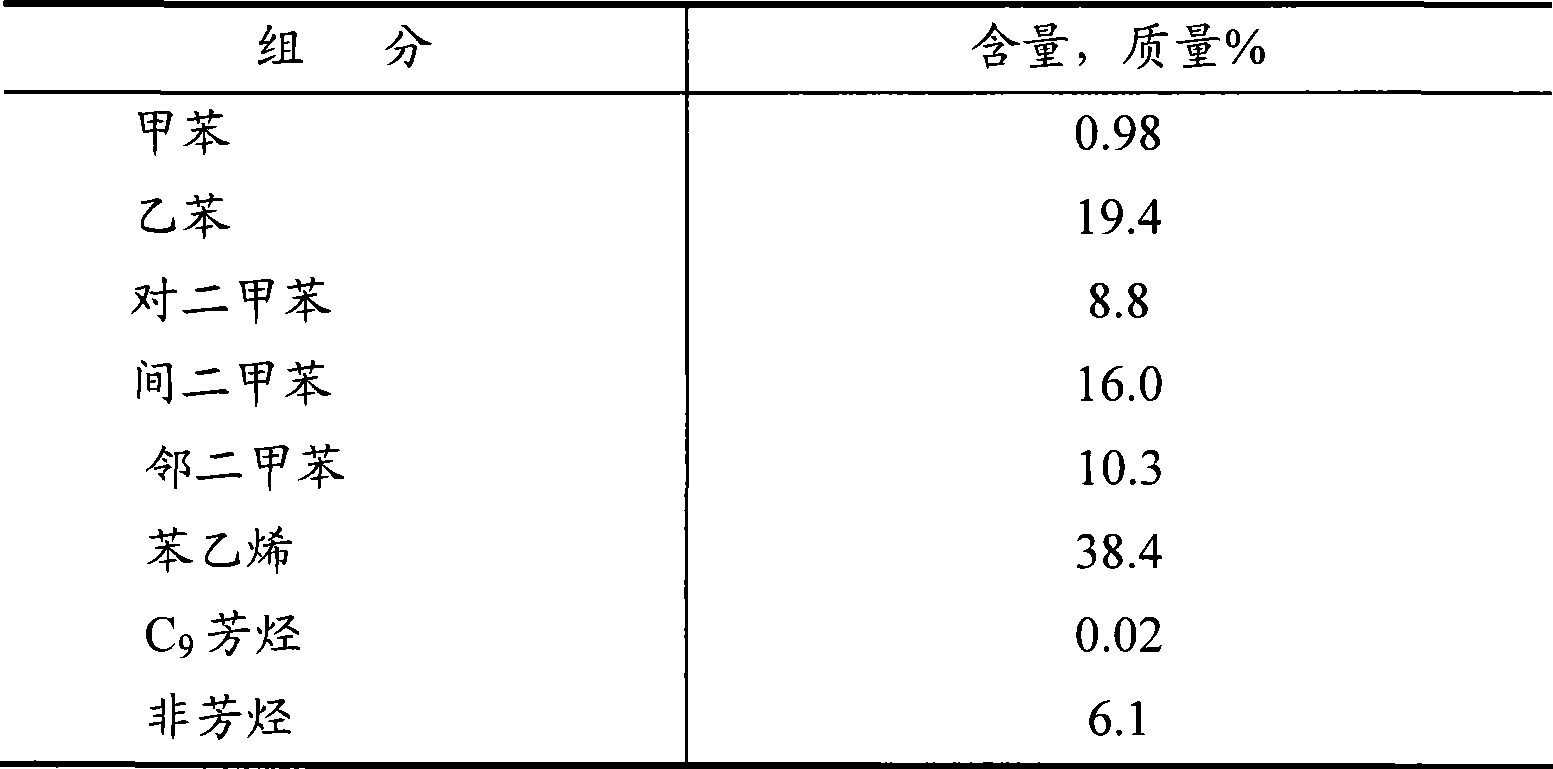

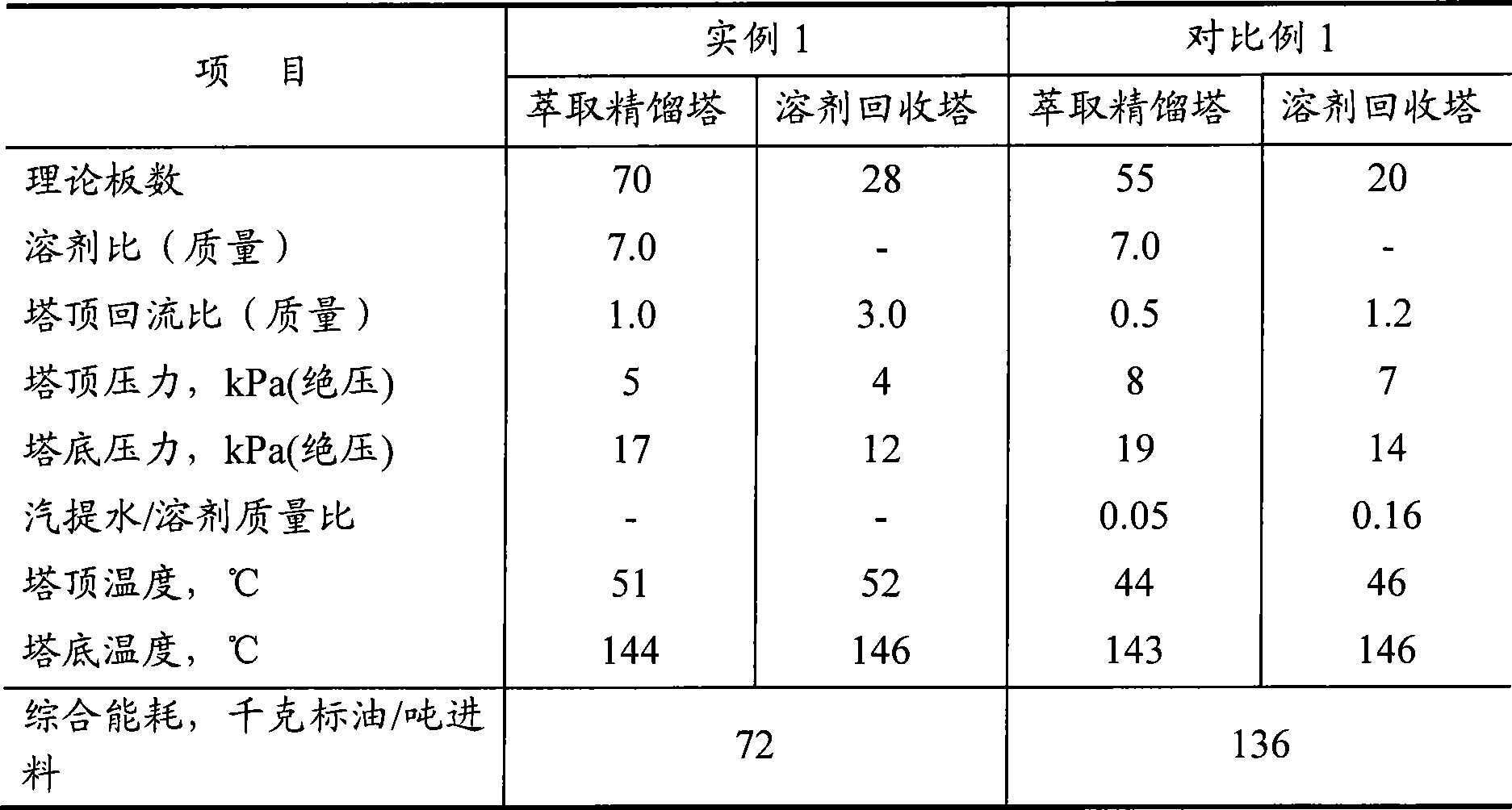

[0027] pyrolysis gasoline C 8 The distillate is used as raw material, and its composition is listed in Table 1. according to figure 1 In the process shown, extractive distillation is carried out on the raw material to recover styrene therein, and the purity of the separated styrene is required to be 99.9% by mass, and the recovery rate is 95% by mass. The composite solvent used contains 80% by mass of main solvent sulfolane and 20% by mass of co-solvent p-diethylbenzene, and the relative volatility of o-xylene / styrene of the raw material is 1.65 as determined by experiments. The operating conditions and energy consumption of the extractive distillation tower and solvent recovery tower are shown in Table 2.

example 2

[0036] By the method of example 1 from pyrolysis gasoline C 8 Separation of styrene in the fraction, the difference is that the composite solvent used contains 85% by mass of the main solvent 2-methylpyrrolidone and 15% by mass of co-solvent trimethylene, and the relative volatility of o-xylene / styrene measured by the experiment is 1.67 , See Table 3 for the operating conditions and energy consumption of the extractive distillation tower and the solvent recovery tower when the styrene purity and yield are the same as in Example 1.

[0037] table 3

[0038]

[0039] As can be seen from Table 3, the composite solvent can effectively reduce the temperature at the bottom of the two towers of the extractive distillation tower and the solvent recovery tower, and minimize the polymerization loss of styrene. On the premise of reaching the same product purity and recovery rate, Compared with Comparative Example 1, the operating energy consumption is reduced by 38%.

example 3

[0041] By the method of example 1 from pyrolysis gasoline C 8 Separation of styrene in the fraction, the difference is that the n-butylbenzene containing 60 mass % N-methylpyrrolidone, 15 mass % diethylene glycol and 25 mass % n-butylbenzene in the composite solvent that adopts, wherein main solvent is N-methyl pyrrolidone and Diethylene glycol, cosolvent is n-butylbenzene, and the o-xylene / styrene relative volatility of experimental measurement is 1.67, and the operation of extraction rectification tower, solvent recovery tower is all the same under the situation of example 1 in styrene purity and yield Conditions and energy consumption are shown in Table 4.

[0042] Table 4

[0043]

[0044] As can be seen from Table 4, under the premise of achieving the same product purity and recovery rate, the operating energy consumption of the composite solvent used in the present invention is significantly reduced by 42% compared with Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com