High wear resistance alloy for slitting roller and manufacturing method thereof

A high wear-resistant, rolling technology, applied in the field of high wear-resistant alloys, can solve the problems of large matrix splitting, loss of matrix protection, and unsatisfactory microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: According to the composition weight percentage in Table 1, smelting in a vacuum intermediate frequency induction furnace, the process steps are: put pig iron, scrap steel, ferrochrome, ferromolybdenum, ferrotungsten, niobium and other alloys into the smelting furnace for heating and melting , and put the ferro-vanadium into the furnace to heat and melt 20 minutes before the molten steel is released; raise the temperature of the molten iron in the smelting furnace to 1500°C-1600°C, add the ferrosilicon and ferromanganese in batches after the aluminum is fully deoxidized , rare earth and ferro-titanium are added by pouring into the bag; when the temperature rises to 1490-1520°C, aluminum is inserted again for deoxidation and then released; by centrifugal casting, when the centrifugal casting molten steel is formed in the mold barrel, when the temperature drops to 1350°C, the A powerful electromagnetic induction coil is added to the outside of the centrifugal ...

Embodiment 2

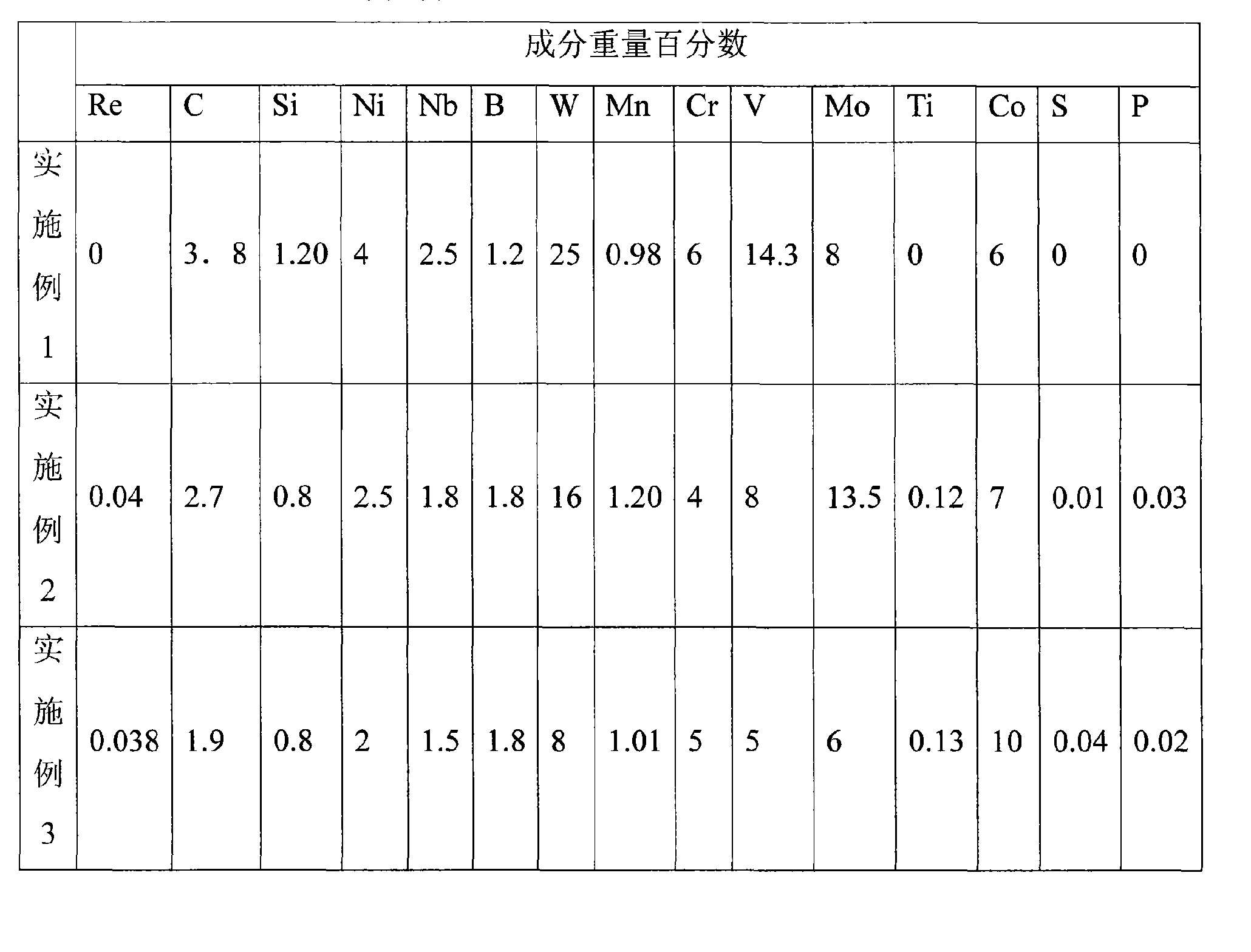

[0023] The process steps of embodiment 2 and embodiment 3 are the same as embodiment 1, and their composition weight percentages are shown in table 1.

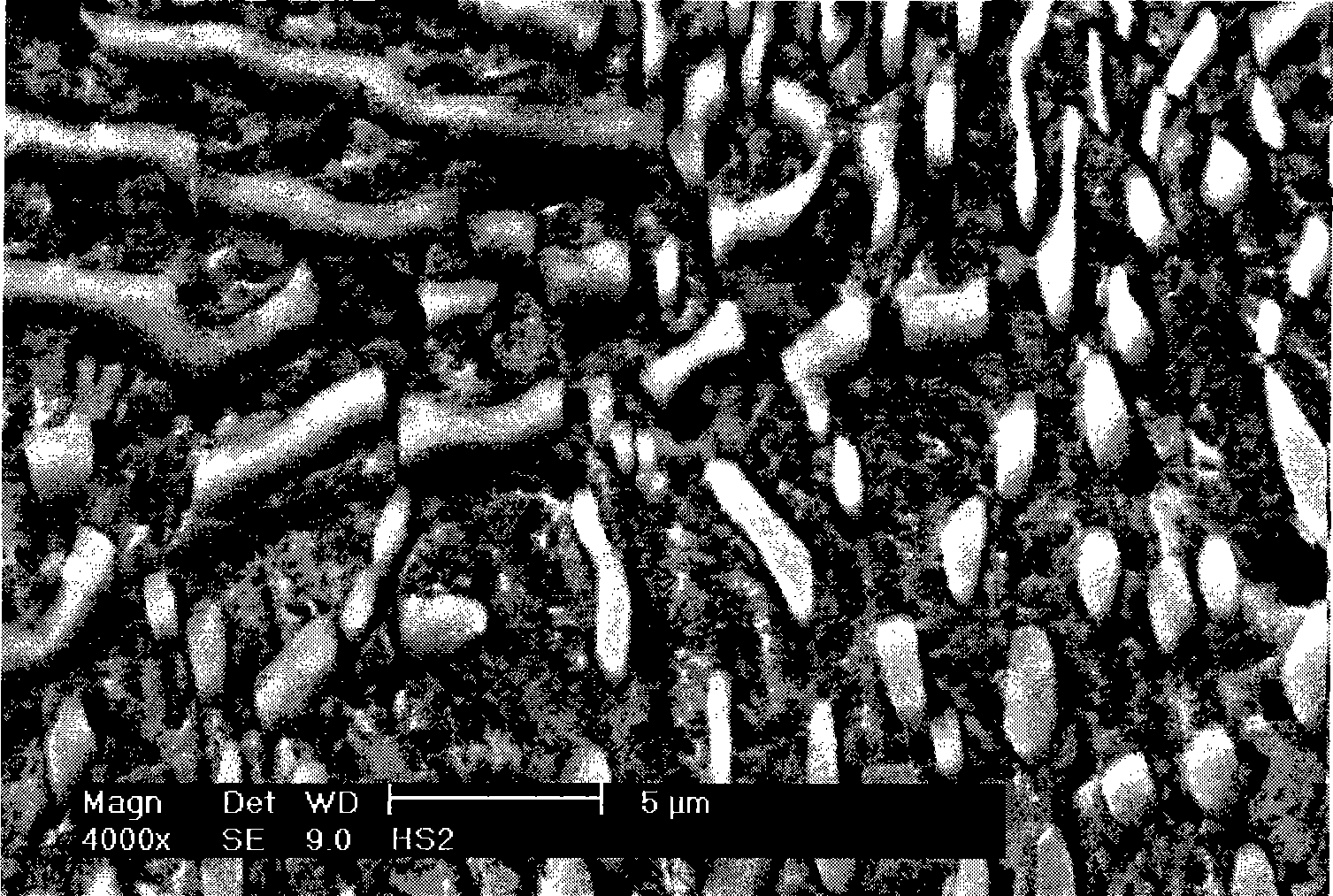

[0024] The metallographic structure diagram of the alloy that the present invention obtains is shown in figure 1 .

[0025] Table 1 Chemical Composition

[0026]

[0027] The rest is iron and unavoidable impurity elements.

[0028] The wedge-shaped test pieces of the alloys obtained in Example 1, Example 2, and Example 3 were wire-cut and ground into 10×10×55 mm samples. The mechanical properties and wear resistance are shown in Table 2. The wear test was carried out on a ML-10 pin-on-disk wear tester with a load of 1300g and an abrasive of 150 # Al 2 o 3 Water sandpaper, wear time 30min.

[0029] Table 2 Mechanical properties and wear resistance

[0030]

Hardness HRC Impact toughness α

k(J / cm2) Abrasion (mg) Example 1 68.0 9.6 0.75 Example 2 66.0 8.3 1.15 Example 3 62.7 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com