Fuel battery using hydration non-perfluocarbon hydrocarbon ion-exchange membrane

A technology of hydrocarbons and fuel cells, applied in fuel cells, fuel cell components, battery electrodes, etc., can solve the problems of fuel cell performance degradation and instability, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

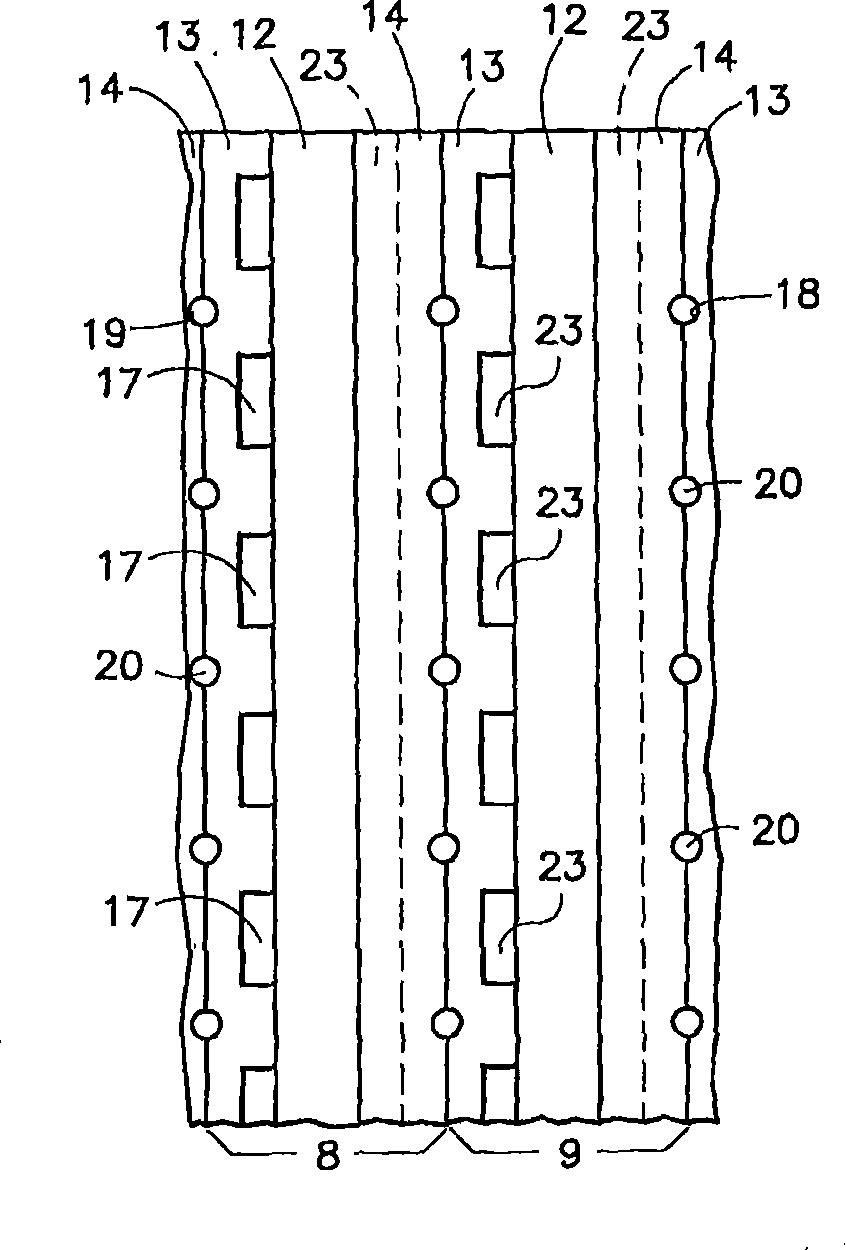

[0021] refer to figure 1 , shows part of a pair of fuel cells 8,9. Each fuel cell has a set of electrode assemblies 12 , porous and hydrophilic fuel reactant gas flow field plates 13 and porous and hydrophilic oxidant reactant gas flow field plates 14 . The fuel reactant gas flow field plate 13 contains fuel flow channels 17 and grooves 18 which, together with the grooves 19 in the oxidant reactant gas flow field plate 14, form channels 20 for hydrating the liquid state of the membrane. water and used to remove product water from the cathode. The oxidant reactant gas flow field plate 14 has an oxidant reactant gas flow field channel 23 .

[0022] Channels 20 may be of large cross-section, sufficient to carry sufficient water to convectively cool the fuel cell by transferring sensible heat to the water. This can be achieved with a coolant pump, heat exchanger and controls, or this can be achieved in a passive system that has no pump and relies on convection or other passive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com