SCR granular catalyst substrate and preparation method thereof

A catalyst and granular technology, which is applied in the field of SCR granular catalyst matrix and its preparation, can solve the problems of activated carbon discomfort and other problems, and achieve the effects of low cost, simple preparation process and good loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

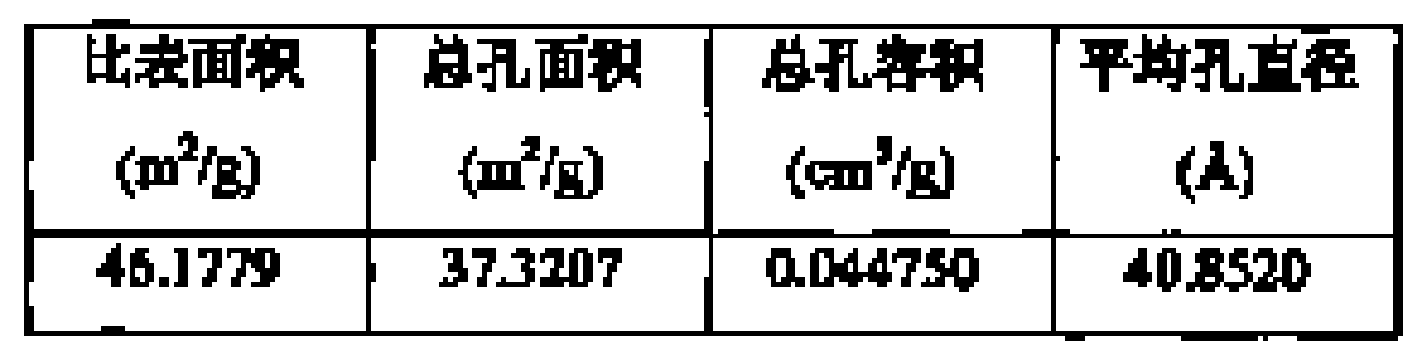

Embodiment 1

[0029] In this embodiment, the SCR granular catalyst substrate includes the following components by mass percentage:

[0030] Base material 88%

[0031] Binder 5%

[0032] Structural aid 4%

[0033] water 3%

[0034] Wherein, the base material is silicon carbide, the binder is carboxymethyl cellulose, and the structural aid is glass fiber.

[0035] The preparation method of the present embodiment comprises the following steps:

[0036] a. Add carboxymethyl cellulose, glass fiber and water to silicon carbide, stir for 1 hour to evenly form catalyst matrix raw materials;

[0037] b. Complete the airtight aging of the evenly stirred catalyst matrix raw materials in a sealed plastic bag for 24 hours, so that the adhesive and the raw materials are evenly combined;

[0038] c. Compress the stale catalyst substrate raw material, and dry it at 105°C for 6 hours, so that the water absorption rate is less than or equal to 1%;

[0039] d. Calcining the dried catalyst substrate raw ...

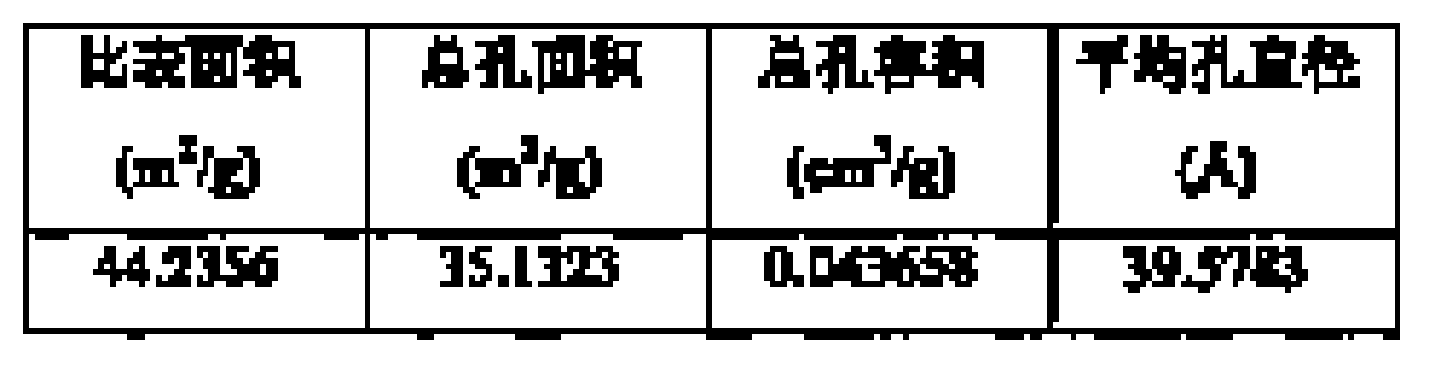

Embodiment 2

[0043] In this embodiment, the SCR granular catalyst substrate includes the following components by mass percentage:

[0044] Base material 93%

[0045] Binder 3%

[0046] Structural aid 1%

[0047] water 3%

[0048] Wherein, the matrix material is silicon carbide, the binder is starch, and the structural aid is carbon fiber.

[0049] The preparation method of the present embodiment comprises the following steps:

[0050] a. Add starch, carbon fiber and water to the silicon carbide, and stir for 1 hour to evenly form the catalyst matrix raw material;

[0051] b. Put the homogeneously stirred catalyst matrix raw materials in a sealed plastic bag to complete airtight aging for 12 hours, so that the adhesive and raw materials can be evenly combined;

[0052] c. Compress the stale catalyst substrate raw material, and dry it at 105°C for 2 hours, so that the water absorption rate is less than or equal to 1%;

[0053] d. Calcining the dried catalyst substrate raw material at 1...

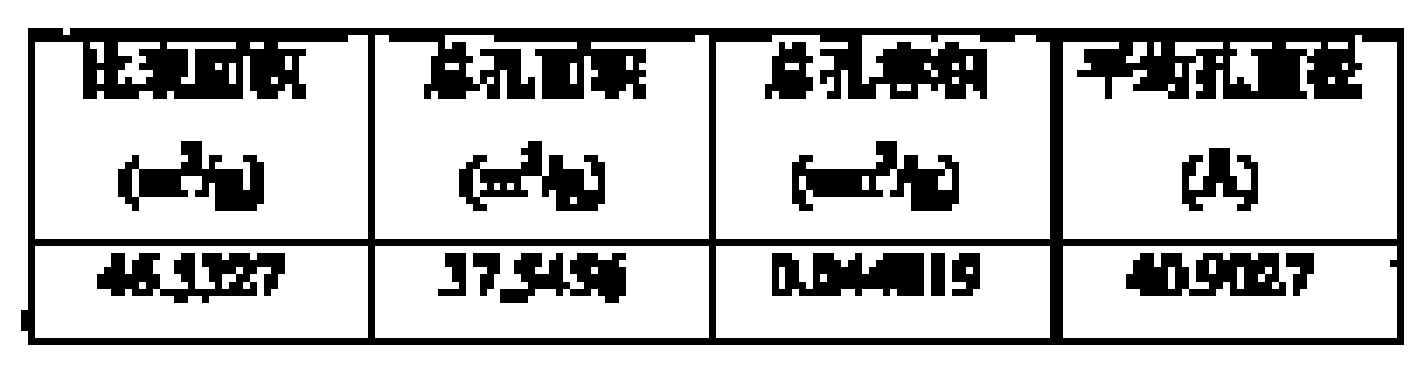

Embodiment 3

[0057] In this embodiment, the SCR granular catalyst substrate includes the following components by mass percentage:

[0058] Base material 80%

[0059] Binder 8%

[0060] Structural aid 4%

[0061] Water 8% of which,

[0062] The matrix material is silicon carbide, the binder is polyvinyl alcohol, and the structural aid is glass fiber.

[0063] The preparation method of the present embodiment comprises the following steps:

[0064] a. Add polyvinyl alcohol, glass fiber and water to the silicon carbide, stir for 1 hour to evenly form the catalyst matrix raw material;

[0065] b. Put the homogeneously stirred catalyst matrix raw materials in a sealed plastic bag to complete airtight staleness for 48 hours, so that the adhesive and raw materials can be evenly combined;

[0066] c. Compress the stale catalyst substrate raw material, and dry it at 105°C for 8 hours, so that the water absorption rate is less than or equal to 1%;

[0067] d. Calcinate the dried catalyst substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com