Method for recycle of copper alloy from waste circuit board and cyclic reconstruction of powder metallurgical product as well as device system thereof

A waste circuit board and powder metallurgy technology, which is applied in the field of environmental protection and resource recovery, can solve the problems of complex metal powder components, immature purification technology, difficulty in refining or recycling, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

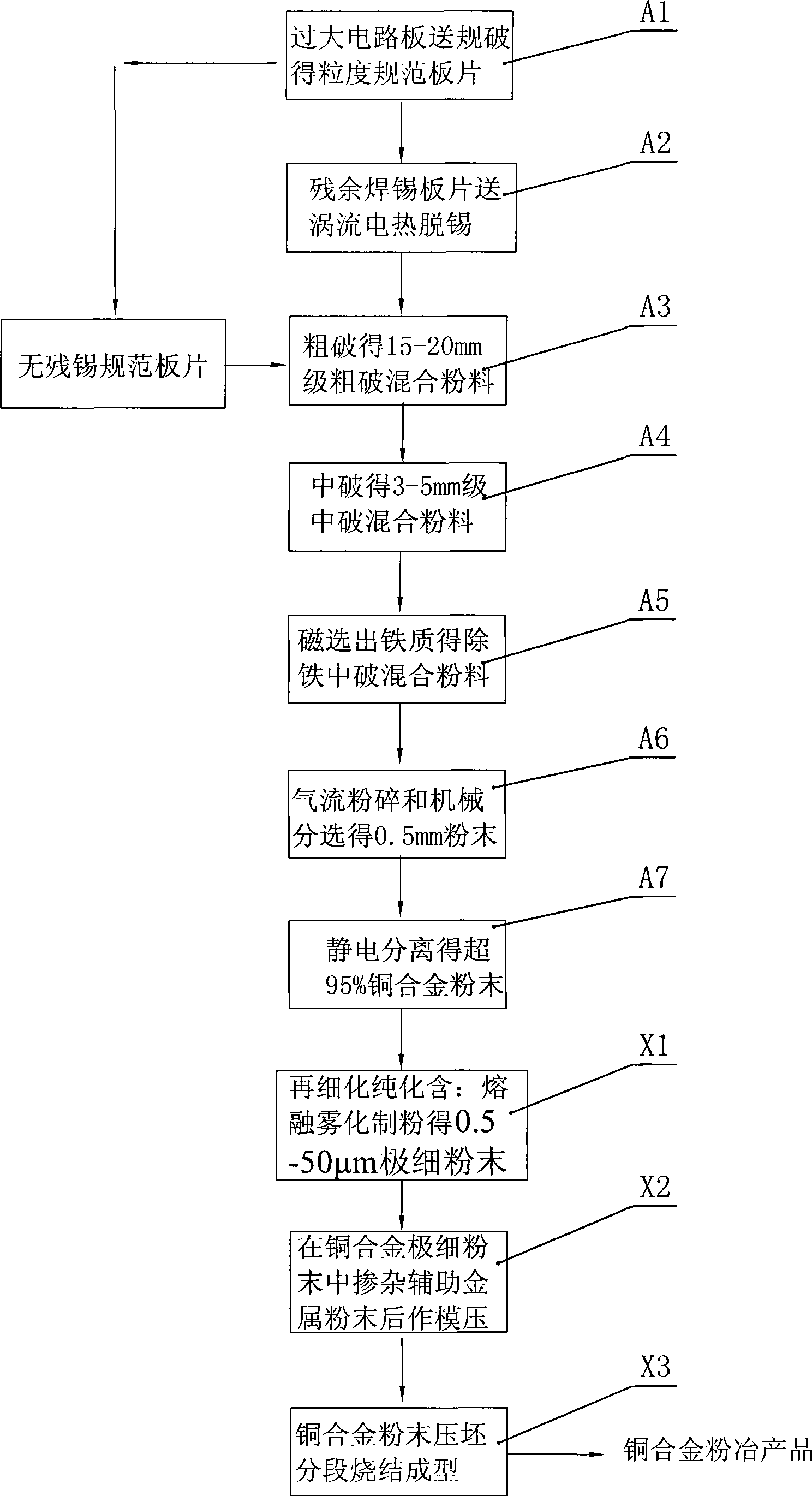

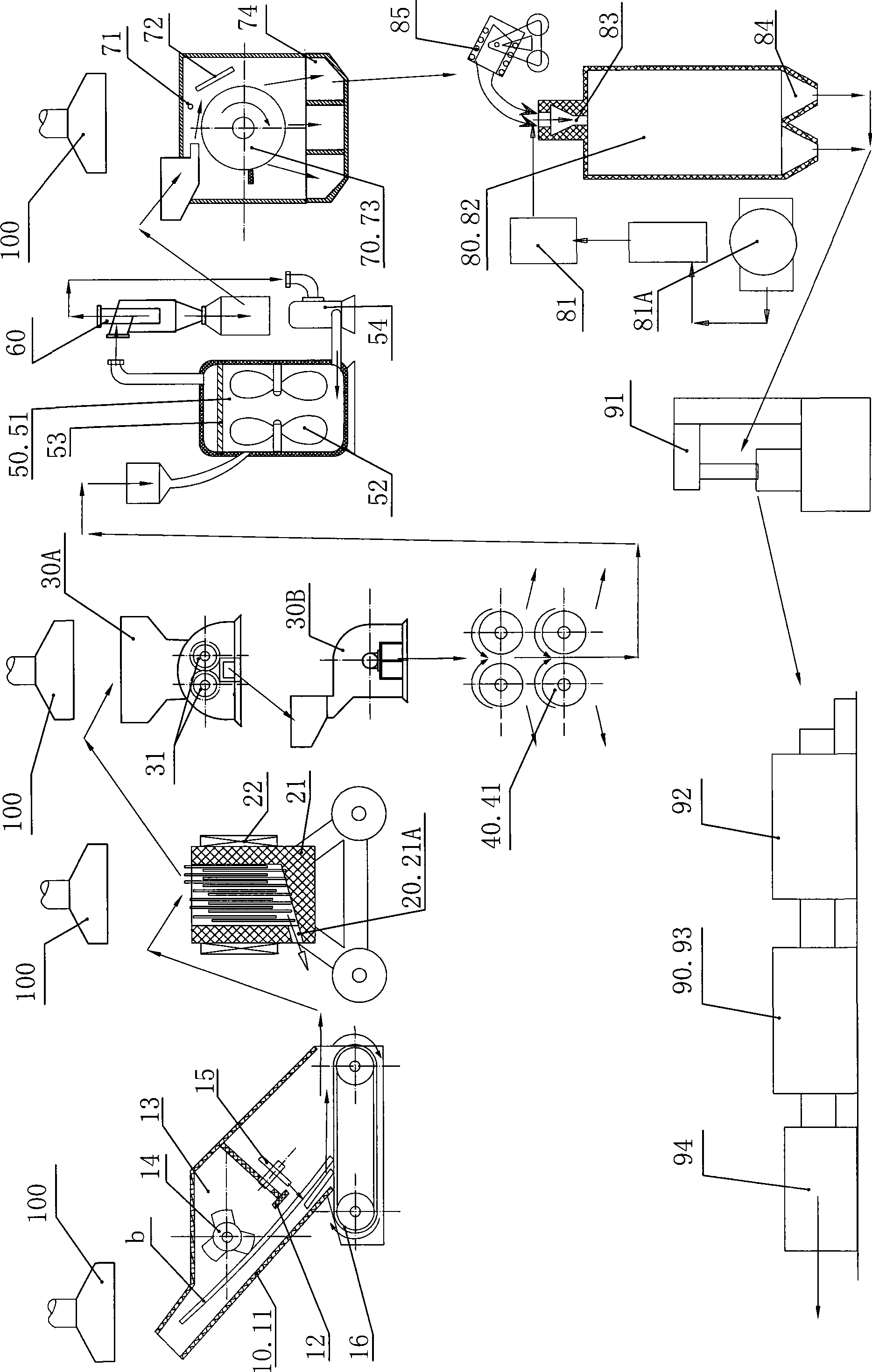

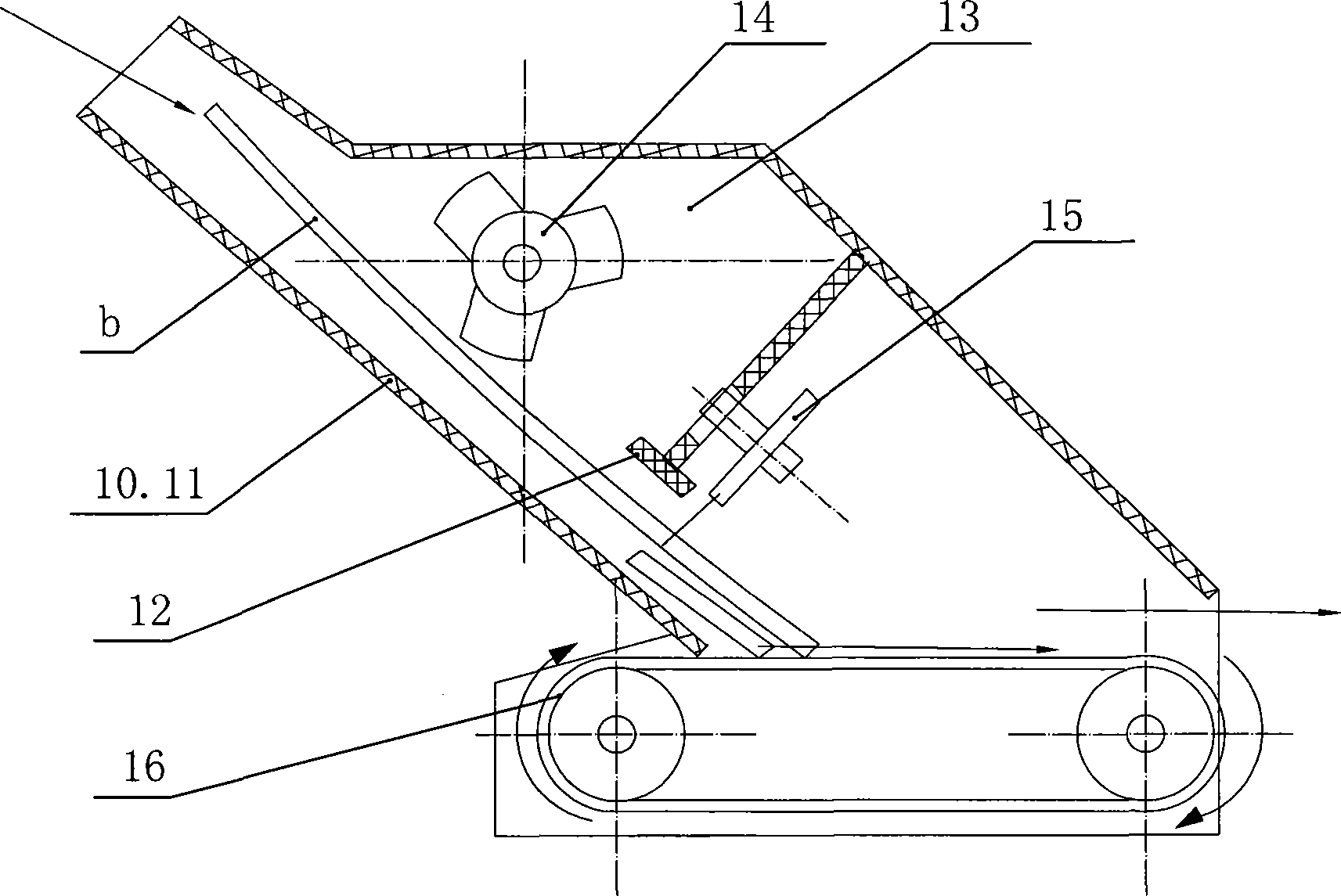

[0026] Such as figure 1 , which is a schematic block diagram showing the principle of an embodiment of the method for recycling copper alloys from waste circuit boards and recycling powder metallurgy products according to the present invention. The method includes, in order:

[0027] A1): Pre-regulate the oversized circuit boards discarded on electronic equipment to obtain standardized circuit boards with a length of no more than 0.5m; A2): Divide the circuit boards with residual solder in batches Put it into an eddy current electric heating detinning furnace for detinning; A3): Coarsely crush the circuit board to obtain a coarsely crushed powder with a particle size of 15-20mm; A4): send the coarsely crushed powder to medium crushing to obtain a mediumly crushed powder with a particle size of 3-5mm , A5): Carry out magnetic separation on the mixed intermediate crushing powder to remove iron, and obtain the intermediate crushing mixed powder for iron removal, A6): perform hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com