Purification method of ultra-pure silicon dioxide sol

A technology of pure silica and purification method, which is applied in the field of purification of ultra-high-purity silica sol, can solve problems such as high cost, adverse effects of chip polishing, and environmental pollution, and achieve short purification time, good purification effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

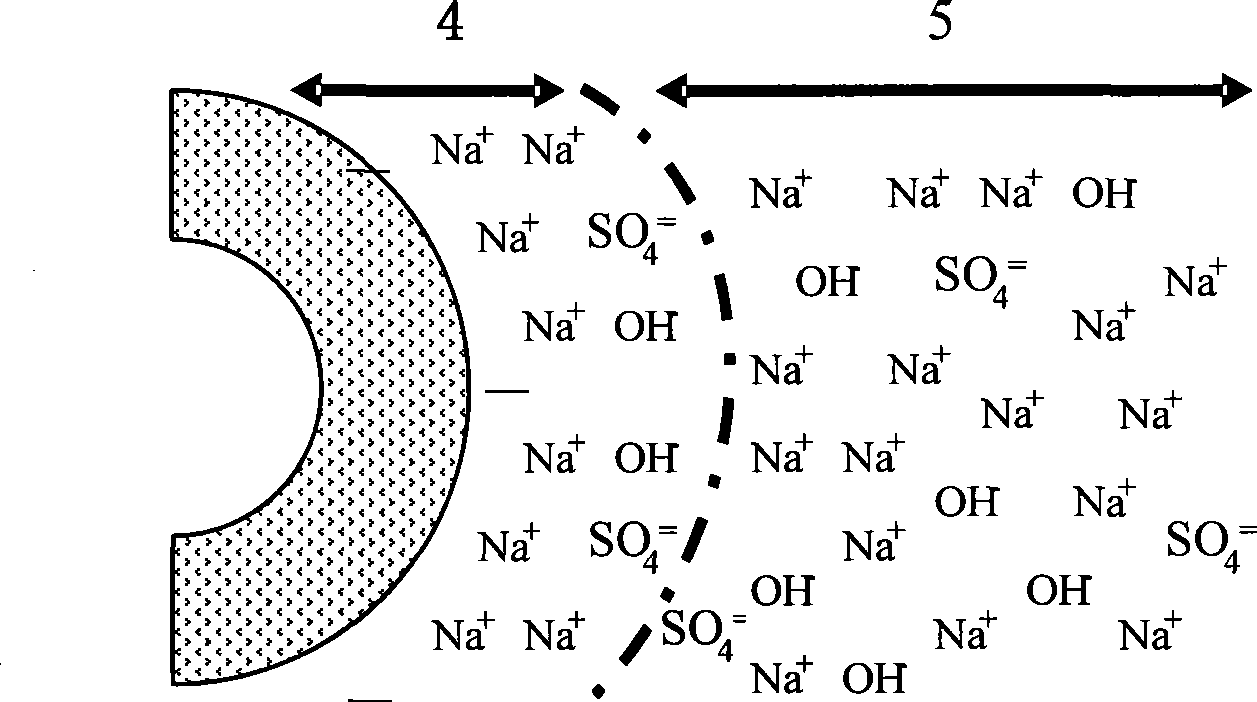

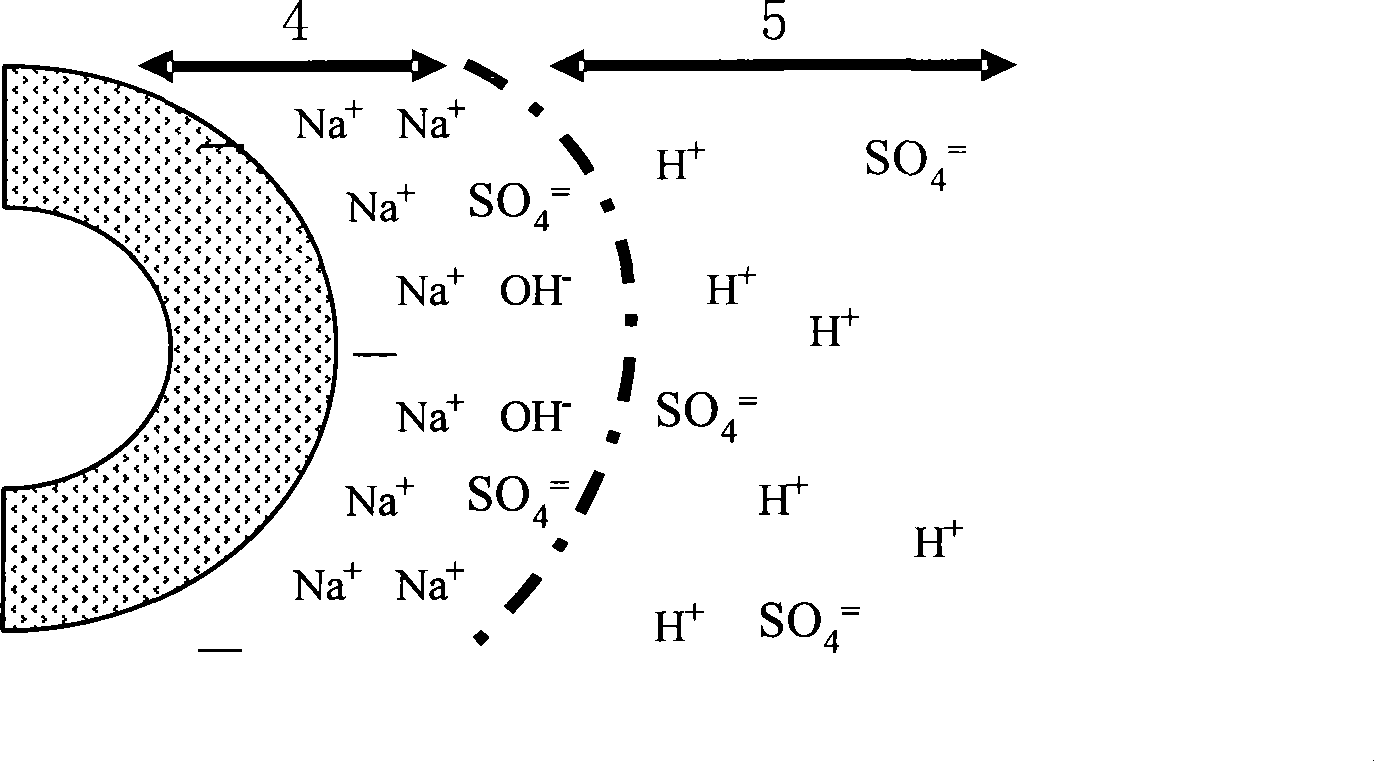

[0050] Strong-acid cation exchange resins have exchange groups -SO on the resin skeleton 3 The cation exchange resin for H is Dowex 50W; the strong base anion exchange resin has an exchange group -N on the resin skeleton. + (CH 3 ) 3 Cl - or -N + (CH 3 ) 3 C 2 h 4 OHCl - Anion exchange resin, choose Dowex 1 for use, strong acid and strong base mixed bed resin is the mixed bed resin of Dowex 50W and Dowex 1.

[0051] The silicon dioxide content of the silica sol to be purified is 30%, the particle size is 30nm, the metal ion content is about 4000ppm, and the anion content is about 1000ppm. The purification method steps of the ultra-high-purity silica sol are as follows,

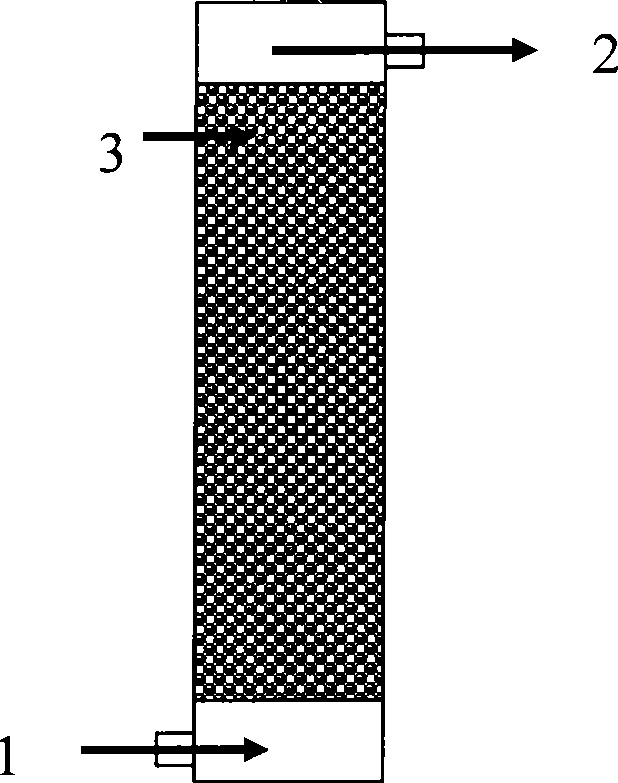

[0052] (1) strong acid type cation exchange resin, strong base type anion exchange resin and strong acid strong base mixed bed resin (in the strong acid strong base mixed bed resin, the volume ratio of strong acid type cation exchange resin and strong base type anion exchange resin is 2.0: 1) Filled ...

Embodiment 2

[0066] Strong-acid cation exchange resins have exchange groups -SO on the resin skeleton 3 The cation exchange resin for H is Amberlite IR-120; the strong base anion exchange resin has an exchange group -N on the resin skeleton. + (CH 3 ) 3 Cl - or -N + (CH 3 ) 3 C 2 h 4 OHCl - The anion-exchange resin for use is Amberlite IRA-400, and the strong acid and strong base mixed bed resin is the mixed bed resin of Amberlite IR-120 and Amberlite IRA-400.

[0067] The silicon dioxide content of the silica sol to be purified is 40%, the particle size is 30nm, the metal ion content is about 2000ppm, and the anion content is about 600ppm. The purification method steps of the ultra-high-purity silica sol are as follows,

[0068] (1) strong acid type cation exchange resin, strong base type anion exchange resin and strong acid strong base mixed bed resin (in the strong acid strong base mixed bed resin, the volume ratio of strong acid type cation exchange resin and strong base type ...

Embodiment 3

[0078] Strong-acid cation exchange resins have exchange groups -SO on the resin skeleton 3 The cation exchange resin of H is Amberlyst 15; the strong base anion exchange resin has an exchange group -N on the resin skeleton. + (CH 3 ) 3 Cl - or -N + (CH 3 ) 3 C 2 h 4 OHCl - The anion-exchange resin for use is Amberlite IRA-410, and the strong acid and strong base mixed bed resin is the mixed bed resin of Amberlyst 15 and Amberlite IRA-410.

[0079] The silicon dioxide content of the silica sol to be purified is 30%, the particle size is 10nm, the metal ion content is about 3400ppm, and the anion content is about 450ppm. The purification method steps of the ultra-high-purity silica sol are as follows,

[0080] (1) strong acid type cation exchange resin, strong base type anion exchange resin and strong acid strong base mixed bed resin (in the strong acid strong base mixed bed resin, the volume ratio of strong acid type cation exchange resin and strong base type anion exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com