Halogen-free flame-retardant system for PA66 engineering plastic preparation, PA66 composite material and preparation thereof

An engineering plastic, PA66 technology, applied in the product PA66 engineering plastic composite material and its preparation, and the field of flame retardant system, can solve the problems of adverse environmental impact and achieve the effect of environmental friendliness and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

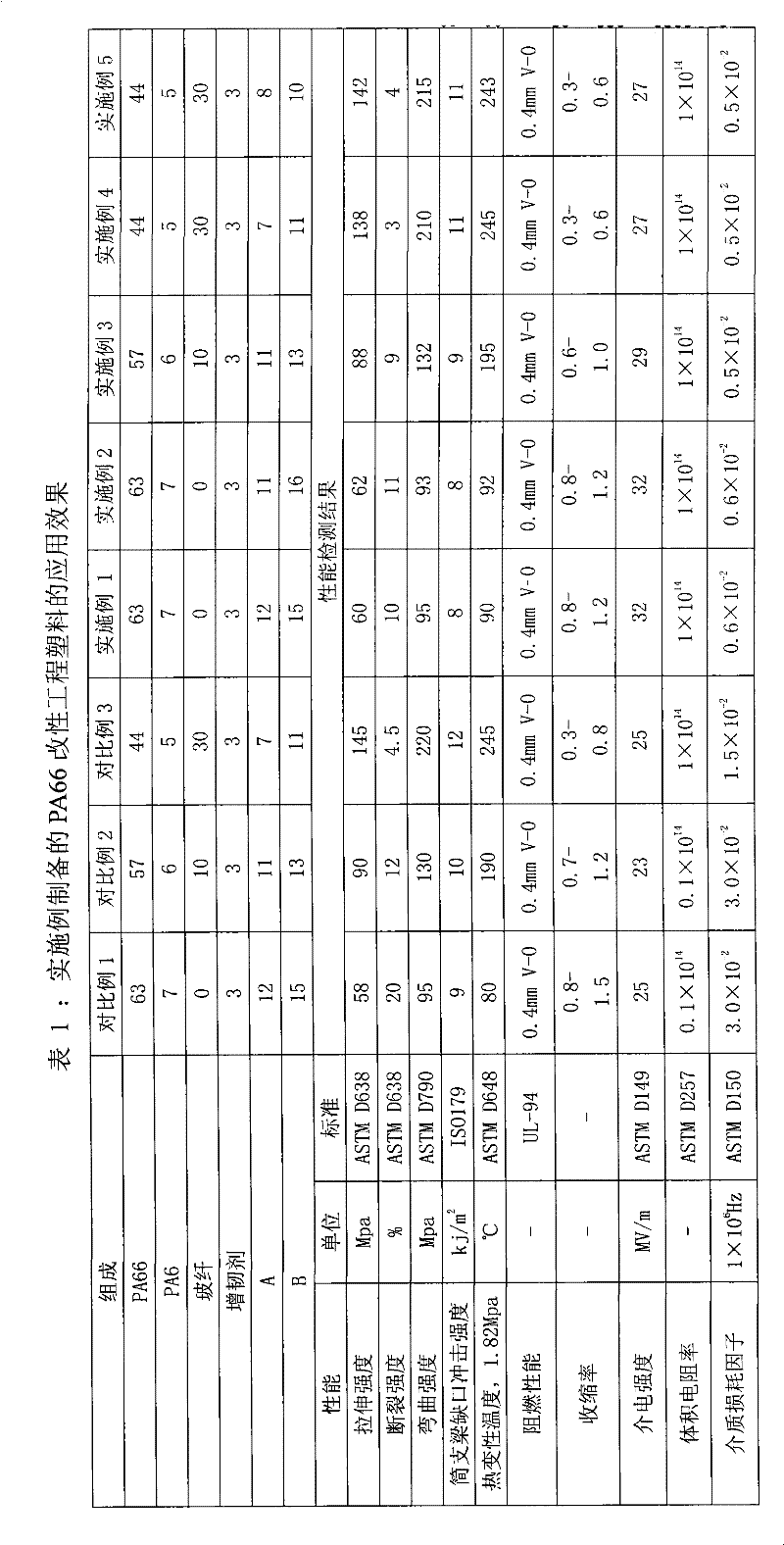

Embodiment 1

[0038] Component A: nucleating agent organic rare earth phosphate salt nucleating agent (R is ethyl) 0.6 kg, antioxidant 0.24 kg 1010 and 0.36 kg 168, external lubricant talc powder 0.96 kg and silicone powder 0.24 kg, carbon Black 4 kg, 5.6 kg PE; total 12 kg

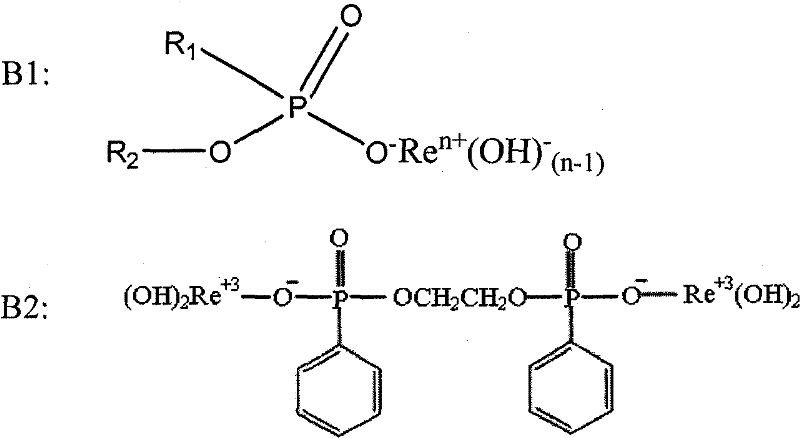

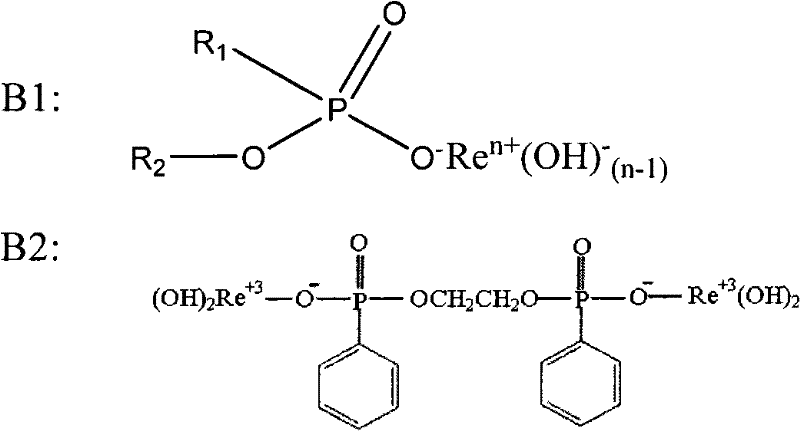

[0039] B component: 15 kg, composed of 10 kg B1(R 1 Ethyl, R 2 It is isopropyl), 3.3 kg of MPP, 1.7 kg of zinc borate, and Re is lanthanum.

[0040] 63 kg of PA66 resin, 7 kg of PA6 resin, 3 kg of maleic anhydride grafted polyethylene as a toughening agent.

[0041] After mixing the above ingredients uniformly, they are introduced into a 53mm twin-screw extruder, extruded, cooled, and pelletized to obtain the final product of Example 1.

Embodiment 2

[0043] A component: nucleating agent organic rare earth phosphate salt nucleating agent (R is ethyl) 0.55 kg, antioxidant 0.22 kg 1010 and 0.33 kg 168, external lubricant talc powder 0.88 kg and silicone powder 0.22 kg, carbon Black 3.7 kg, 5.1 kg PE; 11 kg in total

[0044] B component: 16 kg, mixed with 10.7 kg B2, 3.6 kg MPP and 1.7 kg zinc borate, Re is lanthanum.

[0045] 63 kg of PA66 resin, 7 kg of PA6 resin, 3 kg of maleic anhydride grafted polyethylene as a toughening agent.

[0046] After mixing the above ingredients uniformly, they are introduced into a 53mm twin-screw extruder, extruded, cooled, and pelletized to obtain the final product of Example 2.

Embodiment 3

[0048] A component: nucleating agent organic rare earth phosphate salt nucleating agent (R is ethyl) 0.55 kg, antioxidant 0.22 kg 1010 and 0.33 kg 168, external lubricant talc powder 0.88 kg and silicone powder 0.22 kg, carbon Black 3.7 kg, 5.1 kg PE; 11 kg in total

[0049] B component: 13 kg, mixed with 8.7 kg B2, 2.9 kg MPP, and 1.4 kg zinc borate, Re is lanthanum.

[0050] 57 kg of PA66 resin, 6 kg of PA6 resin, 3 kg of maleic anhydride grafted polyethylene as a toughening agent, and 10 kg of glass fiber.

[0051] After mixing the above ingredients uniformly, they are introduced into a 53mm twin-screw extruder, extruded, cooled, and pelletized to obtain the final product of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com