Zirconium silicon oxide thin film with high dielectric coefficient, and preparation and use thereof

A high dielectric constant, silicon-oxygen technology, used in the field of microelectronic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1. High dielectric constant (ZrO 2 ) 0.5 (SiO 2 ) 0.5 The preparation method of thin film, its preparation steps are as follows:

[0044] a) (ZrO 2 ) 0.5 (SiO 2 ) 0.5 Ceramic target 4 is made of ZrO 2 , SiO 2 prepared by powder mixing solid phase sintering; in the ZrO 2 , SiO 2 After the powders are evenly mixed at a molar ratio of 0.5:0.5, ball milled for 18 hours, then sintered at 1400°C for 5 hours, cooled to make (ZrO 2 ) 0.5 (SiO 2 ) 0.5 Ceramic target 4;

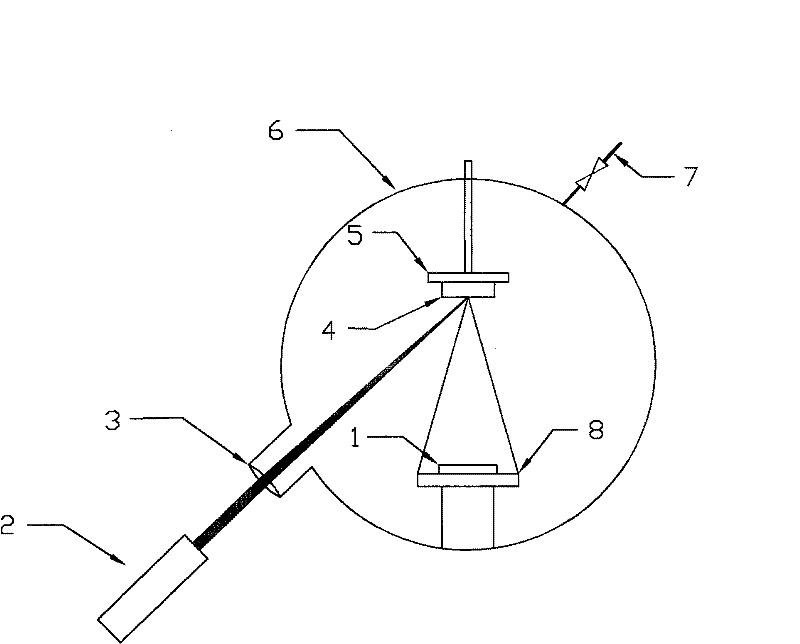

[0045] b) will (ZrO 2 ) 0.5 (SiO 2 ) 0.5 The ceramic target 4 is fixed in a pulsed laser deposition film-making system (such as figure 1 On the target stage 5 shown in ), the silicon substrate 1 is fixed on the substrate stage 8, and they are all placed in the growth chamber 6 of the pulsed laser deposition film-making system;

[0046] c) Use a vacuum pump to evacuate the growth chamber 6 to 1.0×10 through the interface valve 7 of the mechanical pump and the molecular pump -4 Bel...

Embodiment 2

[0049] Embodiment 2. High dielectric constant (ZrO 2 ) 0.8 (SiO 2 ) 0.2 The preparation method of thin film, its preparation steps are as follows:

[0050] a) (ZrO 2 ) 0.8 (SiO 2 ) 0.2 Ceramic target 4 is made of ZrO 2 , SiO 2 prepared by powder mixing solid phase sintering; in the ZrO 2 , SiO 2 After the powders were evenly mixed at a molar ratio of 0.8:0.2, ball milled for 15 hours, then sintered at 1350°C for 4 hours, cooled to produce (ZrO 2 ) 0.8 (SiO 2 ) 0.2 Ceramic target 4;

[0051] b) will (ZrO 2 ) 0.8 (SiO 2 ) 0.2 The ceramic target 4 is fixed in a pulsed laser deposition film-making system (such as figure 1 On the target stage 5 shown in ), the silicon substrate 1 is fixed on the substrate stage 8, and they are all placed in the growth chamber 6 of the pulsed laser deposition film-making system;

[0052]c) Use a vacuum pump to evacuate the growth chamber 6 to 1.0×10 through the interface valve 7 of the mechanical pump and the molecular pump -4 ...

Embodiment 3

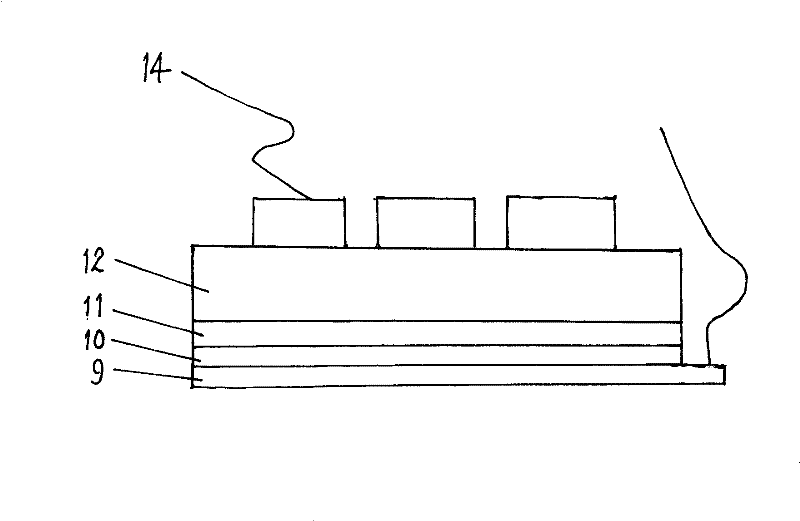

[0055] Embodiment 3. Use high dielectric constant (ZrO 2 ) x (SiO 2 ) 1-x The preparation method of the non-volatile memory memory element of the thin film, the specific preparation steps are as follows:

[0056] 1) Deposit a high dielectric constant (ZrO 2 ) 0.5 (SiO 2 ) 0.5 The thin film tunneling layer 10 has a thickness of 2-3 nanometers;

[0057] 2) In high dielectric constant (ZrO 2 ) 0.5 (SiO 2 ) 0.5 A layer of easily crystallized (ZrO 2 ) 0.8 (SiO 2 ) 0.2 A thin-film charge storage layer 11 with a thickness of 1-1.5 nanometers;

[0058] 3) Easy to crystallize (ZrO 2 ) 0.8 (SiO 2 ) 0.2 A layer of high dielectric constant (ZrO 2 ) 0.5 (SiO 2 ) 0.5 Thin film barrier layer 12, its thickness is 10-15 nanometer;

[0059] 4) Memory element at 800°C N 2 Medium rapid thermal annealing treatment for 5 minutes;

[0060] 5) Deposit the electrode film 13 on the above-mentioned memory element by magnetron sputtering on the stainless steel metal mask, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com